Are you gearing up for an interview for a Welder, Metal Fab position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Welder, Metal Fab and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

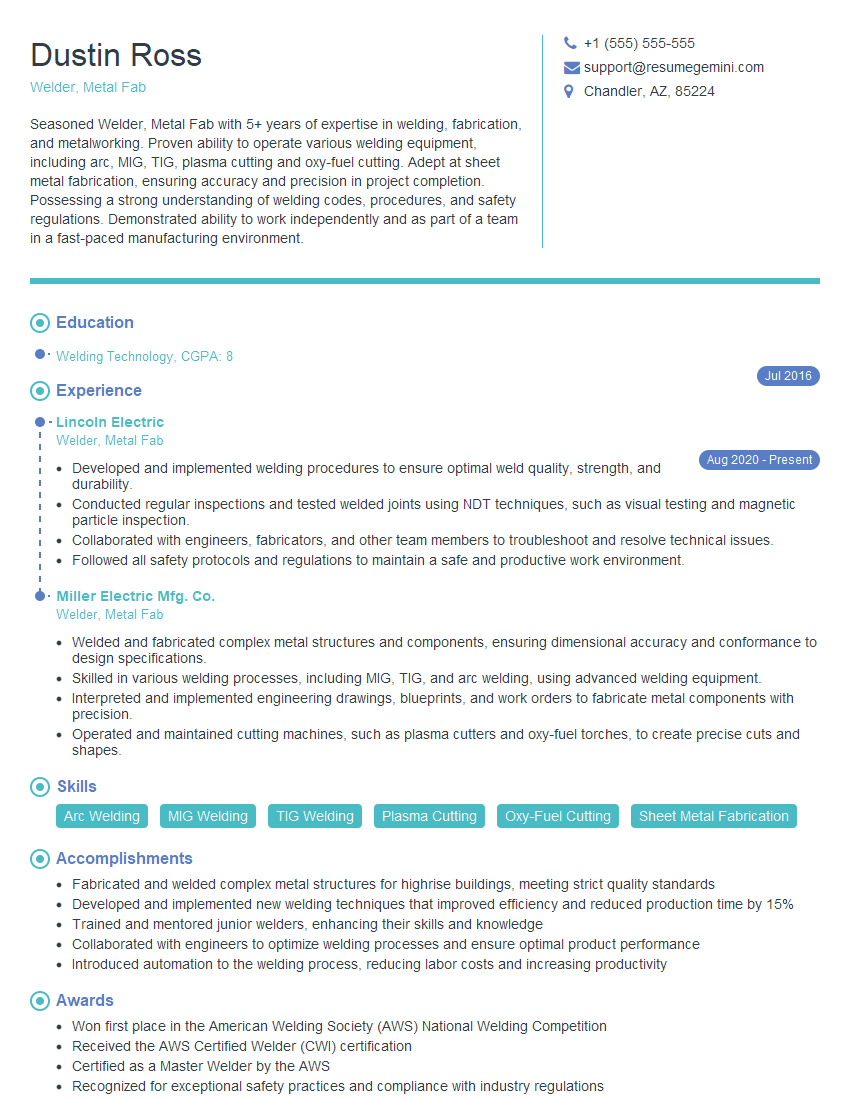

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder, Metal Fab

1. What are the different types of welding processes you are familiar with?

I am proficient in various welding processes, including:

- Gas Metal Arc Welding (GMAW)

- Gas Tungsten Arc Welding (GTAW)

- Shielded Metal Arc Welding (SMAW)

- Flux-Cored Arc Welding (FCAW)

2. Can you describe the steps involved in preparing and welding a metal workpiece?

Surface Preparation

- Clean and degrease the surface

- Remove any rust, paint, or other contaminants

Joint Preparation

- Bevel or edge the joint to create a proper groove

- Ensure proper fit-up and alignment

Welding

- Select appropriate welding parameters (amperage, voltage, wire speed)

- Properly position the torch or electrode

- Maintain a consistent travel speed

Post-Weld Inspection

- Visually inspect the weld for any defects

- Perform non-destructive testing (e.g., dye penetrant or ultrasonic) if necessary

3. What are the safety precautions you observe while welding?

Maintaining a safe work environment while welding is crucial. I adhere to the following precautions:

- Wear appropriate protective gear (e.g., welding helmet, gloves, fire-resistant clothing)

- Inspect equipment before use

- Ensure proper ventilation to avoid fume inhalation

- Ground the workpiece properly

- Keep flammable materials away from the welding area

4. How do you inspect welds for quality?

I utilize various techniques to ensure weld quality:

- Visual inspection for any visible defects (e.g., cracks, porosity)

- Dye penetrant testing to identify surface-breaking cracks

- Ultrasonic testing to detect internal defects

- Radiographic testing for a comprehensive evaluation of weld soundness

5. What are the different joint designs used in metal fabrication?

In metal fabrication, various joint designs are employed depending on the application and load requirements:

- Butt joint

- Edge joint

- T-joint

- Corner joint

- Lap joint

6. How do you calculate the appropriate welding parameters for a given welding process?

Determining optimal welding parameters is crucial. I consider the following factors:

- Material thickness and composition

- Joint design

- Welding process and equipment

- Filler metal properties

- Desired weld quality

7. What are some common defects that can occur in welding and how do you prevent them?

Common Defects

- Porosity

- Cracks

- Undercut

- Slag inclusions

Prevention Measures

- Proper surface preparation and joint fit-up

- Optimizing welding parameters

- Using high-quality filler metal

- Ensuring proper shielding gas coverage

- Minimizing welding time and heat input

8. How do you stay updated on the latest welding techniques and industry best practices?

To maintain my expertise, I engage in continuous learning and development:

- Attend industry conferences and workshops

- Read technical articles and journals

- Participate in online training programs

- Seek mentorship from experienced welders

9. Can you describe your experience in welding different types of metals?

My experience encompasses welding a wide range of ferrous and non-ferrous metals:

- Carbon steel

- Stainless steel

- Aluminum

- Titanium

- Copper alloys

10. How do you handle welding complex assemblies and structures?

Welding complex assemblies requires a systematic approach:

- Proper planning and sequencing

- Accurate measurement and alignment

- Welding in smaller sections to minimize distortion

- Use of jigs and fixtures for precision

- Regular inspection and quality control

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder, Metal Fab.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder, Metal Fab‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding and metal fabrication professionals play a vital role in industries ranging from construction and manufacturing to automotive and aerospace. They possess specialized skills and knowledge in welding, metalworking, and fabrication techniques, enabling them to create, repair, and maintain metal structures and components.

1. Welding and Fabrication

Welders and metal fabricators are responsible for joining metal pieces using various welding methods, including arc welding, MIG welding, TIG welding, and spot welding. They cut, shape, and form metal using tools and machinery, such as saws, grinders, and press brakes, to create complex structures and components.

- Perform welding and fabrication operations according to blueprints and specifications.

- Read and interpret technical drawings and instructions.

2. Quality Control and Inspection

Welders and metal fabricators must adhere to strict quality standards and ensure that their work meets industry requirements. They perform quality control inspections on welds and fabricated components, using tools such as calipers, gauges, and non-destructive testing equipment.

- Conduct visual and dimensional inspections to ensure welds and components meet specifications.

- Perform non-destructive testing (NDT) to evaluate weld quality and identify defects.

3. Material Handling and Equipment Maintenance

Welders and metal fabricators work with heavy materials and equipment, so they must possess the ability to handle and move them safely. They are also responsible for maintaining their own equipment, ensuring that it is in good working order and calibrated to meet industry standards.

- Handle and transport materials and equipment safely and efficiently.

- Perform basic equipment maintenance and repairs.

4. Safety and Compliance

Welders and metal fabricators work in potentially hazardous environments, so they must adhere to all safety regulations and procedures. They are required to wear proper personal protective equipment (PPE), such as welding helmets, gloves, and respirators.

- Follow safety procedures and wear appropriate PPE.

- Comply with industry regulations and standards.

Interview Tips

Preparing for an interview is crucial to showcase your skills and experience effectively. Here are some tips to help you ace your interview for a Welder, Metal Fab position:

1. Research the Company and Position

Learn about the company’s history, values, and products or services. This will help you understand their business and how your skills and experience align with their needs.

- Visit the company’s website and social media pages.

- Read industry news and articles.

2. Practice Your Answers to Common Interview Questions

Prepare for questions about your welding and metal fabrication experience, skills, and qualifications. Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples.

- Tell me about your experience in welding and metal fabrication.

- What are your strengths and weaknesses as a welder?

- Can you describe a challenging welding project you worked on?

3. Highlight Your Skills and Experience

Emphasize your welding and metal fabrication skills, including the specific welding methods you are proficient in and your experience with different materials. Quantify your accomplishments whenever possible to demonstrate your impact on the job.

- I have over 5 years of experience in arc welding and MIG welding.

- I have fabricated complex metal structures for the construction industry.

4. Show Enthusiasm and Passion

Let the interviewer know that you are passionate about welding and metal fabrication. Describe why you enjoy the work and how it aligns with your career goals. Explain how you stay up-to-date with the latest industry trends and technologies.

- I am passionate about welding and enjoy the challenge of creating something new.

- I am constantly learning about new welding techniques and technologies.

5. Dress Professionally and Arrive on Time

First impressions matter, so dress professionally for your interview. Arrive on time and be prepared to answer questions confidently and enthusiastically. Being punctual and well-dressed shows that you are serious about the position and respect the interviewer’s time.

- Wear a suit or business casual attire.

- Arrive at least 15 minutes early for your interview.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welder, Metal Fab interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!