Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welder Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welder Operator so you can tailor your answers to impress potential employers.

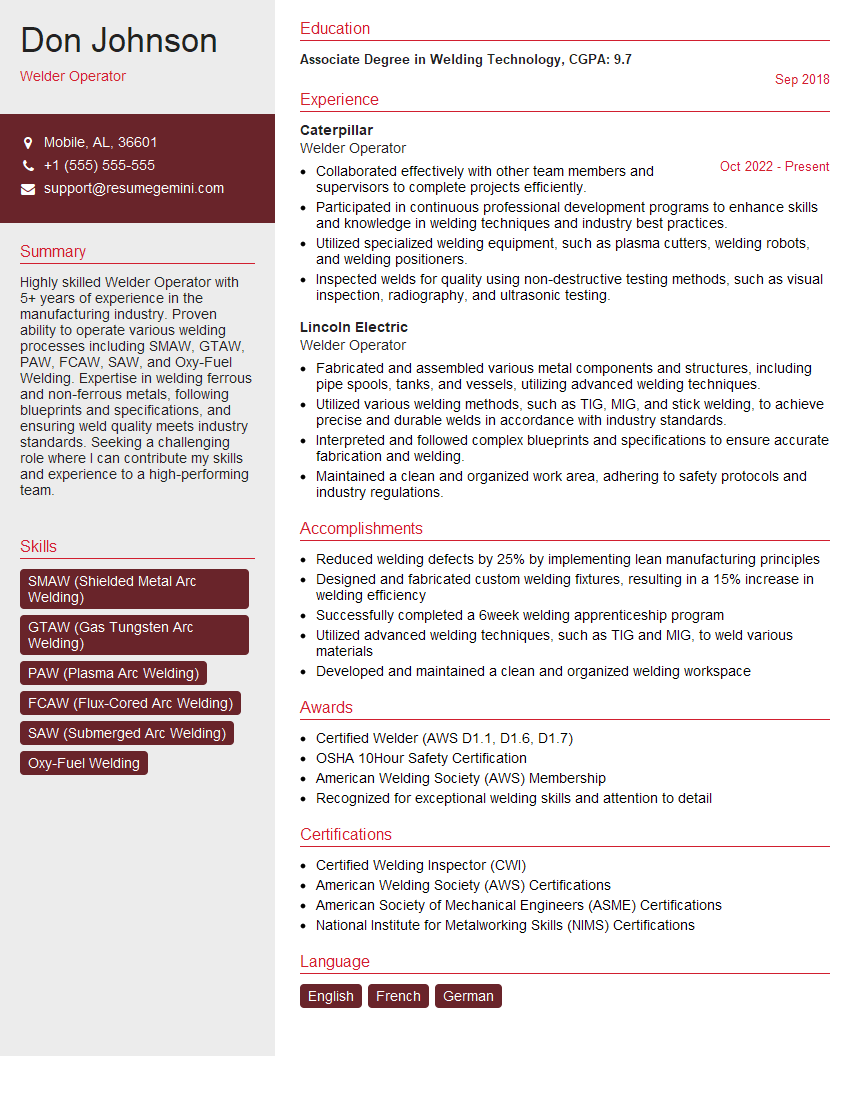

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder Operator

1. Explain the different types of welding processes and when each is typically used?

There are several welding processes, each with its own applications. Some common types include:

- Shielded Metal Arc Welding (SMAW): Uses consumable electrodes covered in flux and is suitable for various metals and thicknesses.

- Gas Metal Arc Welding (GMAW): Uses a continuous wire electrode and a shielding gas, suitable for thin to medium-thick metals.

- Gas Tungsten Arc Welding (GTAW): Uses a non-consumable tungsten electrode and a shielding gas, providing high-quality welds for thin metals.

- Flux-Cored Arc Welding (FCAW): Uses a tubular electrode filled with flux, offering versatility and high productivity.

- Submerged Arc Welding (SAW): Uses a consumable electrode covered in granular flux, providing high deposition rates and deep penetration.

2. How do you determine the correct welding parameters for a specific application?

Determining welding parameters involves considering:

- Material Type: Thickness, composition, and weldability.

- Joint Design: Type of joint, edge preparation, and fit-up.

- Welding Process: Specific process used and its capabilities.

- Equipment: Power source, welding machine, and accessories.

- Code or Standard: Requirements and specifications for the application.

3. What are the common welding defects and how do you prevent them?

Welding defects can include:

- Porosity: Holes or voids in the weld metal, prevented by proper shielding and clean materials.

- Inclusions: Foreign materials trapped in the weld, prevented by using clean materials and proper welding techniques.

- Cracking: Fracture in the weld or base metal, prevented by selecting the appropriate materials and welding parameters.

- Undercut: Groove along the edge of the weld, prevented by using proper welding techniques and avoiding excessive heat input.

- Burn-through: Penetration of the base metal by the weld, prevented by controlling heat input and using the correct parameters.

4. Describe the safety precautions that must be taken when welding.

- Wear appropriate personal protective equipment (PPE), including helmet, gloves, and protective clothing.

- Ensure proper ventilation to remove welding fumes and gases.

- Inspect equipment before use and follow safe operating procedures.

- Secure workpieces to prevent movement and accidents.

- Be aware of potential fire hazards and have firefighting equipment nearby.

5. How do you interpret welding symbols on blueprints?

Welding symbols on blueprints provide information about the weld joint, including:

- Reference Line: Indicates the location of the weld.

- Arrow: Shows the direction of welding.

- Weld Symbol: Specifies the type of weld.

- Tail: Provides additional information, such as the weld size.

- Dimensions: Indicates the length, width, and height of the weld.

6. How do you troubleshoot common welding problems, such as spatter or cold welds?

Troubleshooting welding problems involves identifying the root cause and implementing corrective actions:

- Spatter: Excessive welding spatter can be caused by high voltage settings, incorrect shielding gas, or contaminated materials.

- Cold Welds: Incomplete fusion or lack of penetration can result from low heat input, improper welding techniques, or poor joint preparation.

- Porosity: Holes in the weld can be caused by moisture or contamination, improper shielding gas, or excessive heat input.

- Cracking: Fractures in the weld can be caused by residual stresses, improper heat treatment, or excessive heat input.

7. How do you maintain and calibrate welding equipment?

- Regularly inspect and clean equipment, including torches, nozzles, and cables.

- Calibrate welding machines according to manufacturer’s instructions to ensure accurate settings.

- Use appropriate consumables and shielding gases of the correct quality.

- Follow recommended maintenance schedules and consult with qualified technicians for repairs.

8. What are the different types of welding joints and when are they used?

Common welding joints include:

- Butt Joint: Joining two pieces of metal end-to-end.

- Edge Joint: Joining two pieces of metal along their edges.

- Tee Joint: Joining two pieces of metal at a right angle.

- Corner Joint: Joining two pieces of metal at a 90-degree angle.

- Lap Joint: Overlapping two pieces of metal and welding them together.

9. How do you comply with quality standards and codes in welding?

- Understand and follow industry standards, such as AWS D1.1 or ASME Boiler and Pressure Vessel Code.

- Qualify welding procedures and welders to ensure they meet the required standards.

- Inspect welds according to codes and specifications.

- Maintain documentation of welding procedures, qualifications, and inspections.

- Work closely with quality control personnel to ensure compliance.

10. How do you stay up-to-date with the latest welding techniques and technologies?

- Attend industry conferences, workshops, and training sessions.

- Read technical journals and publications.

- Network with other welders and industry professionals.

- Seek opportunities to work on projects that involve new or advanced welding technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welder Operators are responsible for welding various metal components and structures in a production or fabrication environment. Their responsibilities include:

1. Welding Tasks

Welders follow blueprints and work orders to perform a range of welding tasks, including:

- Joining metal parts using different welding techniques, such as MIG, TIG, and Arc welding

- Ensuring weld quality meets specifications and industry standards

- Preparing welding surfaces by cleaning, grinding, and assembling parts

2. Machine Operation

Welders operate welding machines and equipment to complete their tasks, including:

- Setting up and calibrating welding machines

- Selecting and installing appropriate welding electrodes and shielding gases

- Monitoring welding parameters, such as voltage, amperage, and travel speed

3. Quality Control

Welders play a vital role in quality control by:

- Inspecting welds for defects and imperfections

- Conforming to established welding procedures and safety regulations

- Documenting welding activities and maintaining records

4. Collaboration and Communication

Welders collaborate and communicate with colleagues, including:

- Working closely with engineers and fabricators to understand welding requirements

- Communicating any potential issues or delays to supervisors

- Maintaining a clean and organized work area

Interview Tips

To prepare effectively for a Welder Operator interview, consider the following tips:

1. Technical Knowledge and Skills

Ensure you have a strong understanding of welding principles, techniques, and safety practices. Familiarize yourself with different welding machines and their capabilities.

- Highlight your experience with various welding techniques (e.g., MIG, TIG, Arc) and the types of metals you have worked with.

- Provide examples of projects where you demonstrated proficiency in welding, fabrication, and quality control.

2. Industry Knowledge

Research the welding industry and stay updated on current trends and advancements. This shows your interest and enthusiasm for the field.

- Discuss your knowledge of welding codes, standards, and regulations.

- Show your understanding of the applications of welding in different industries, such as construction, automotive, and manufacturing.

3. Safety and Hazard Awareness

Emphasize your commitment to safety and your knowledge of welding-related hazards. Describe how you prioritize safety measures in your work.

- Share your experience in following safety protocols, using personal protective equipment, and maintaining a clean work environment.

- Explain how you assess and mitigate potential risks associated with welding.

4. Problem-Solving and Critical Thinking

Welding often involves problem-solving and critical thinking. Highlight your ability to analyze and troubleshoot welding issues.

- Describe how you approached and resolved welding defects or challenges in previous roles.

- Provide examples of how you applied problem-solving techniques to improve welding processes or outcomes.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.