Are you gearing up for an interview for a Welder Tech position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Welder Tech and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

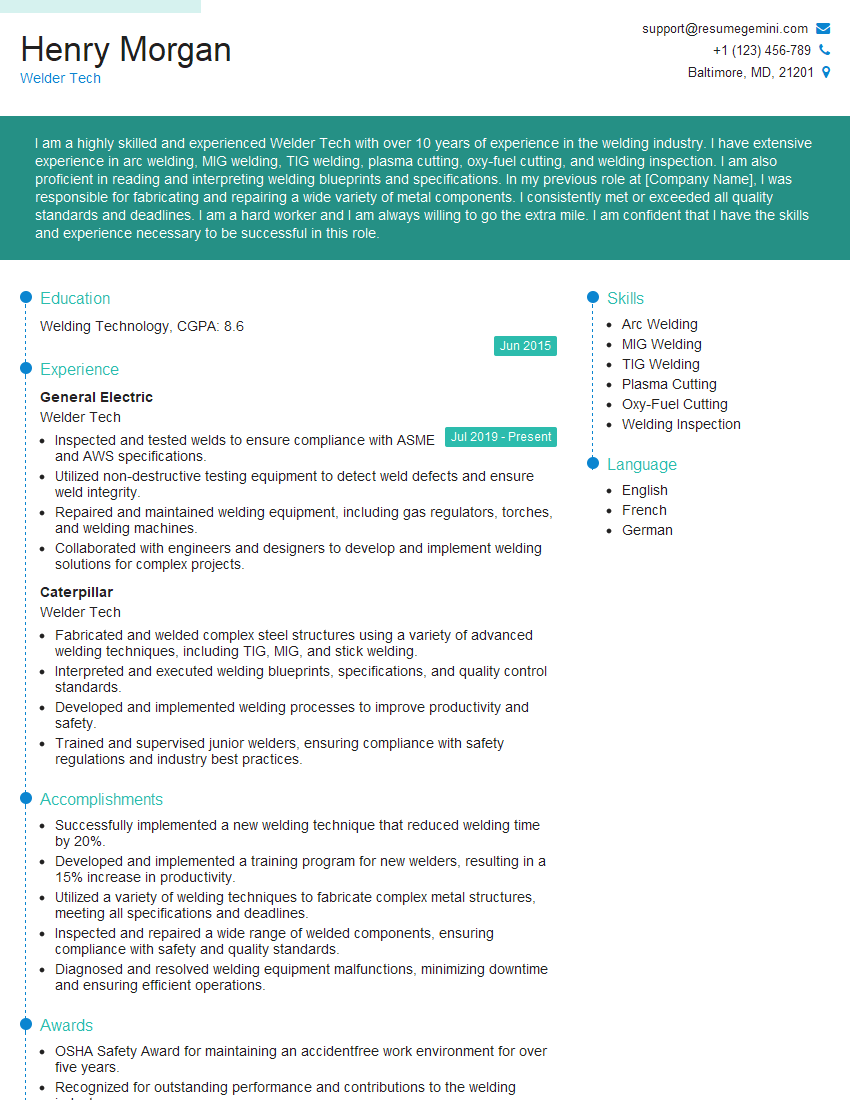

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welder Tech

1. Tell me about your experience with different welding processes?

- I have worked with a variety of welding processes, including MIG, TIG, and stick welding.

- I have experience welding a wide range of materials, including steel, aluminum, and stainless steel.

2. What are the different types of welds and when would you use each type?

Fusion welding

- Melting the base metal

- Used to create strong, permanent joints

Solid-state welding

- Applying pressure without melting the base metal

- Used to create bonds that are less strong than fusion welds

Brazing

- Melting a filler metal that has a lower melting point than the base metal

- Used to join dissimilar metals or create leak-proof seals

3. What are the safety precautions that you take when welding?

- Wear appropriate personal protective equipment, including a welding helmet, gloves, and clothing.

- Ensure that the work area is well-ventilated.

- Inspect equipment regularly and make sure it is in good working order.

4. What are the most common welding defects and how do you prevent them?

- Porosity: Caused by gases trapped in the weld metal. Prevent by using clean materials and shielding the weld from the atmosphere.

- Cracking: Caused by excessive stress or heat. Prevent by using proper welding techniques and preheating the base metal.

- Undercutting: Caused by the weld metal not fully penetrating the base metal. Prevent by using the correct welding parameters and techniques.

5. What types of welding codes and standards are you familiar with?

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.2: Structural Welding Code – Aluminum

- ASME Boiler and Pressure Vessel Code

6. How do you stay up-to-date on the latest welding technologies and techniques?

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Participate in online forums and discussion groups.

7. What is your experience with welding in different positions?

- I have experience welding in all positions, including flat, horizontal, vertical, and overhead.

- I am proficient in using a variety of welding techniques, including MIG, TIG, and stick welding, in all positions.

8. What is your experience with welding different types of materials?

- I have experience welding a variety of materials, including steel, aluminum, stainless steel, and cast iron.

- I am familiar with the different welding techniques and parameters required for each type of material.

9. What is your experience with welding in different environments?

- I have experience welding in a variety of environments, including indoors, outdoors, and in confined spaces.

- I am able to adapt my welding techniques and procedures to meet the specific requirements of each environment.

10. What is your experience with welding to different specifications?

- I have experience welding to a variety of specifications, including AWS, ASME, and ISO.

- I am familiar with the different requirements of each specification and am able to meet or exceed them.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welder Tech.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welder Tech‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welder Techs are responsible for welding and fabricating metal structures, and their work plays a crucial role in various industries, including construction, manufacturing, and transportation. The key responsibilities of a Welder Tech include:

1. Welding and Fabrication

Performing welding and fabrication tasks using various welding processes, such as arc welding, MIG welding, and TIG welding.

- Reading and interpreting engineering drawings to understand the required specifications.

- Selecting appropriate welding techniques and materials based on the project requirements.

2. Quality Control

Ensuring the quality of welds and fabricated components through visual inspection and non-destructive testing.

- Inspecting welds for defects, such as cracks, porosity, and undercuts, using visual aids and measuring tools.

- Conducting non-destructive testing, such as radiography, ultrasonic testing, and magnetic particle testing, to identify any internal flaws or defects.

3. Safety and Compliance

Adhering to all safety regulations and guidelines related to welding and fabrication, including proper use of personal protective equipment and following established safety protocols.

- Wearing appropriate personal protective equipment, such as welding helmets, gloves, and protective clothing, to minimize exposure to fumes, sparks, and heat.

- Following established safety procedures to prevent accidents and ensure a safe working environment.

4. Material Handling and Setup

Handling and setting up welding equipment, materials, and workpieces, including preparing and cleaning surfaces for welding.

- Setting up and adjusting welding equipment, such as welding machines, torches, and gas regulators, according to the required welding parameters.

- Preparing and cleaning workpieces by removing rust, dirt, and other contaminants to ensure proper weld quality.

Interview Tips

To prepare for a Welder Tech interview, it’s important to understand the key responsibilities of the role and to highlight your relevant skills and experience. Here are some interview tips and hacks that can help you ace the interview:

1. Research the Company and Position

Before the interview, take the time to thoroughly research the company you’re applying to and the specific Welder Tech position. This will help you understand the company’s culture, values, and the specific requirements of the role.

- Visit the company’s website to learn about their history, mission, and products or services.

- Read industry news and articles to stay up-to-date on the latest trends and technologies in welding.

2. Practice Your Welding Skills

If possible, practice your welding skills before the interview. This will help you feel confident and demonstrate your abilities to the interviewer. You can practice on scrap metal or take a welding class at a local community college.

- Set up a welding station in your garage or workshop.

- Practice different welding techniques, such as arc welding, MIG welding, and TIG welding.

3. Prepare for Common Interview Questions

There are certain interview questions that are commonly asked in Welder Tech interviews. By preparing for these questions, you can give well-thought-out and confident answers.

- Tell me about your experience with welding and fabrication.

- What are your strengths and weaknesses as a welder?

- Why are you interested in this position at our company?

4. Highlight Your Safety Knowledge and Compliance

Safety is of paramount importance in welding. Make sure to emphasize your knowledge of safety regulations and your commitment to following established safety protocols.

- Explain your understanding of the Occupational Safety and Health Administration (OSHA) regulations for welding.

- Describe your experience with using personal protective equipment and following safety procedures.

5. Ask Questions

At the end of the interview, ask thoughtful questions to demonstrate your interest in the position and the company. This is also an opportunity to clarify any information or address any concerns you may have.

- What are the company’s safety standards and procedures?

- What are the opportunities for professional development and advancement within the company?

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welder Tech interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.