Are you gearing up for a career in Welding, Brazing, and Burning Machine Repairer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Welding, Brazing, and Burning Machine Repairer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

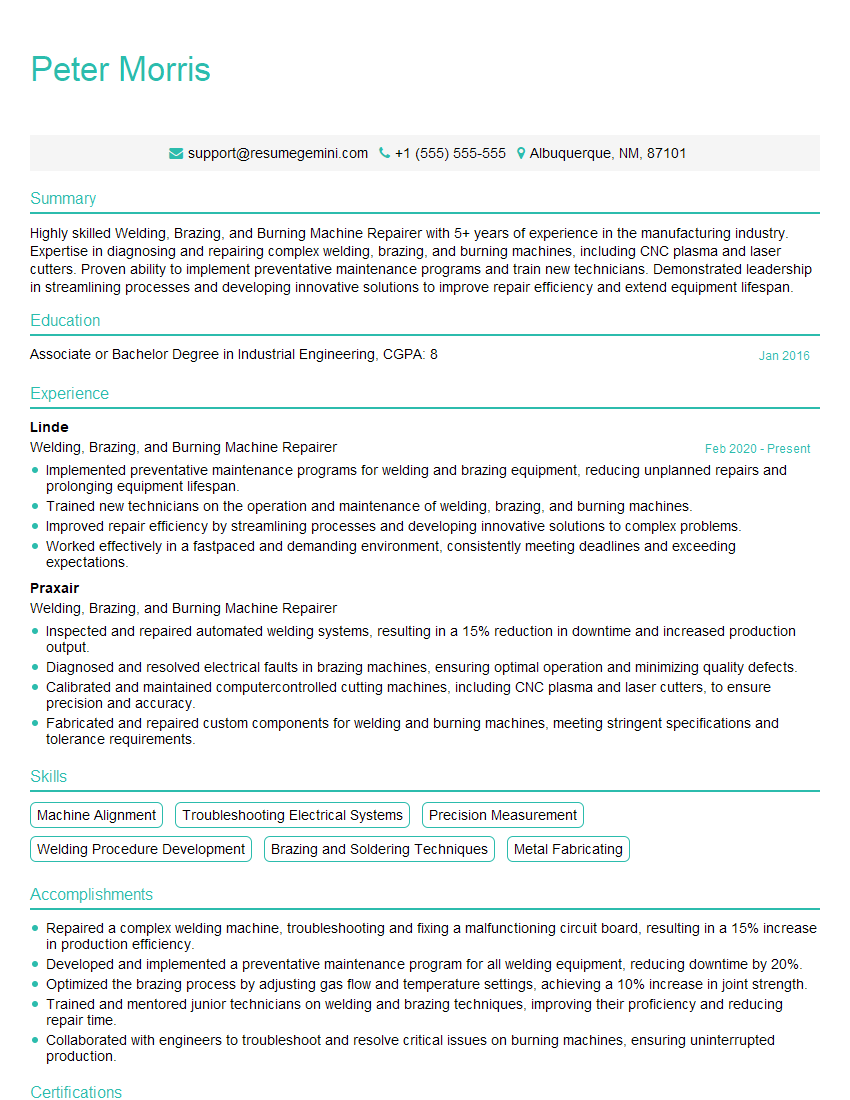

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding, Brazing, and Burning Machine Repairer

1. How do you determine the correct welding process for a specific application?

When selecting the appropriate welding process, several factors must be considered, including:

- The type of metal being welded

- The thickness of the metal

- The desired joint strength

- The availability of equipment and materials

2. What are the most common welding defects, and how can they be prevented?

Porosity

- Caused by gas entrapment during welding

- Prevented by proper shielding gas selection and welding technique

Inclusions

- Caused by foreign matter in the weld

- Prevented by proper cleaning of the welding area and consumables

3. How do you ensure the quality of your welds?

To ensure the quality of my welds, I follow strict quality control procedures, including:

- Visual inspection of welds for defects

- Non-destructive testing (NDT) to detect hidden defects

- Destructive testing to determine the strength and integrity of welds

4. What are the safety precautions that must be taken when welding?

When welding, it is essential to take the following safety precautions:

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, and fire-resistant clothing

- Ensure proper ventilation to avoid inhalation of welding fumes

- Handle welding equipment safely to prevent electrical shock or burns

- Store and use welding materials properly to prevent fires or explosions

5. What types of brazing and burning equipment are you familiar with?

I am familiar with a wide range of brazing and burning equipment, including:

- Oxy-acetylene torches

- Propane torches

- Induction brazing equipment

- Laser brazing equipment

6. How do you troubleshoot problems with welding, brazing, and burning machines?

When troubleshooting problems with welding, brazing, and burning machines, I follow a systematic approach, including:

- Identifying the symptoms of the problem

- Inspecting the equipment for potential causes

- Consulting technical manuals or seeking expert advice

- Testing and replacing components as necessary

7. What are the latest advancements in welding, brazing, and burning technology?

I stay up-to-date on the latest advancements in welding, brazing, and burning technology, including:

- Robotic welding systems

- Laser welding and cutting

- Hybrid welding processes

- New materials and alloys

8. How do you stay up-to-date on the latest welding, brazing, and burning techniques?

To stay up-to-date on the latest welding, brazing, and burning techniques, I:

- Attend industry conferences and workshops

- Read technical journals and articles

- Consult with experts in the field

- Experiment with new techniques and technologies

9. What is your preferred welding process, and why?

My preferred welding process is gas tungsten arc welding (GTAW) because it provides:

- Excellent weld quality and precision

- Versatility in welding various metals

- Control over the welding arc and heat input

10. How do you handle working with different types of metals?

When working with different types of metals, I:

- Adjust the welding parameters (e.g., heat input, travel speed) to suit the specific metal

- Use appropriate filler materials and shielding gases

- Consider the metallurgical properties of the metals to prevent defects or failures

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding, Brazing, and Burning Machine Repairer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding, Brazing, and Burning Machine Repairer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Welding, Brazing, and Burning Machine Repairer plays a critical role in maintaining the proper functioning of welding, brazing, and burning machines in various industries. Their primary responsibilities encompass the following:

1. Machine Maintenance and Repair

• Inspect, troubleshoot, diagnose, and repair a wide range of welding, brazing, and burning machines and their components.

• Perform preventative maintenance tasks, such as lubrication, calibration, and replacement of worn parts.

- Example: Inspecting and adjusting gas flow regulators on a plasma cutting machine to ensure optimal cutting performance.

- Example: Troubleshooting and resolving electrical faults in a welding power source to restore its operation.

2. Installation and Commissioning

• Install and commission new or overhauled welding, brazing, and burning machines.

• Ensure proper alignment, grounding, and connection to power and gas sources.

- Example: Installing and commissioning a CNC plasma cutting table, ensuring its accurate movement and efficient cutting operations.

- Example: Connecting a gas-powered brazing torch to an oxygen and acetylene supply, adjusting pressures for optimal flame characteristics.

3. Technical Support and Training

• Provide technical support to end users, assisting with machine operation, troubleshooting, and safety procedures.

• Conduct training for operators on the safe and proper use of welding, brazing, and burning machines.

- Example: Troubleshooting a welding machine over the phone, guiding the operator through step-by-step diagnostics to identify and resolve the issue.

- Example: Conducting a hands-on training session on the operation of a laser cutter, emphasizing safety precautions and best practices for efficient material processing.

4. Safety Compliance

• Ensure that all welding, brazing, and burning operations comply with industry safety standards and regulations.

• Conduct regular safety inspections and implement corrective actions as required.

- Example: Verifying that all welding booths are equipped with proper ventilation and personal protective equipment.

- Example: Training operators on the proper handling and storage of flammable gases used in welding processes.

Interview Tips

To ace the interview for a Welding, Brazing, and Burning Machine Repairer position, it’s crucial to prepare thoroughly. Here are some valuable tips:

1. Research the Company and Industry

• Gather information about the company, its products or services, and the specific industry it operates in.

• Understand the company’s mission, values, and recent developments.

- Example: Research the company’s website, industry news, and social media presence to gain insights into their operations and market position.

- Example: Read industry publications and attend webinars to stay updated on the latest trends and best practices in welding technology.

2. Practice Common Interview Questions

• Prepare answers to common interview questions, such as “Tell me about yourself” and “Why are you interested in this position?”

• Practice answering technical questions related to your skills and experience in welding, brazing, and burning machine repair.

- Example: Practice describing your experience in troubleshooting and repairing a specific type of welding machine, highlighting your diagnostic and problem-solving abilities.

- Example: Prepare an example of a successful repair project you completed, emphasizing your attention to detail and commitment to quality.

3. Showcase Your Skills and Experience

• Highlight your expertise in welding, brazing, and burning machine repair techniques.

• Quantify your accomplishments and provide specific examples to demonstrate your impact.

- Example: Quantify your experience by stating the number of machines you repaired or commissioned, or the percentage improvement you achieved in machine uptime.

- Example: Provide specific examples of complex repairs or troubleshooting challenges you successfully resolved, demonstrating your problem-solving abilities.

4. Emphasize Safety and Compliance

• Emphasize your commitment to safety and compliance with industry regulations.

• Highlight your knowledge of safety protocols and your experience in ensuring safe work practices.

- Example: Explain your role in conducting safety inspections and implementing corrective actions to maintain a safe work environment.

- Example: Describe your experience in training operators on the proper handling and storage of welding gases and equipment.

Next Step:

Now that you’re armed with the knowledge of Welding, Brazing, and Burning Machine Repairer interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Welding, Brazing, and Burning Machine Repairer positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini