Feeling lost in a sea of interview questions? Landed that dream interview for Welding Equipment Repairer Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Welding Equipment Repairer Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

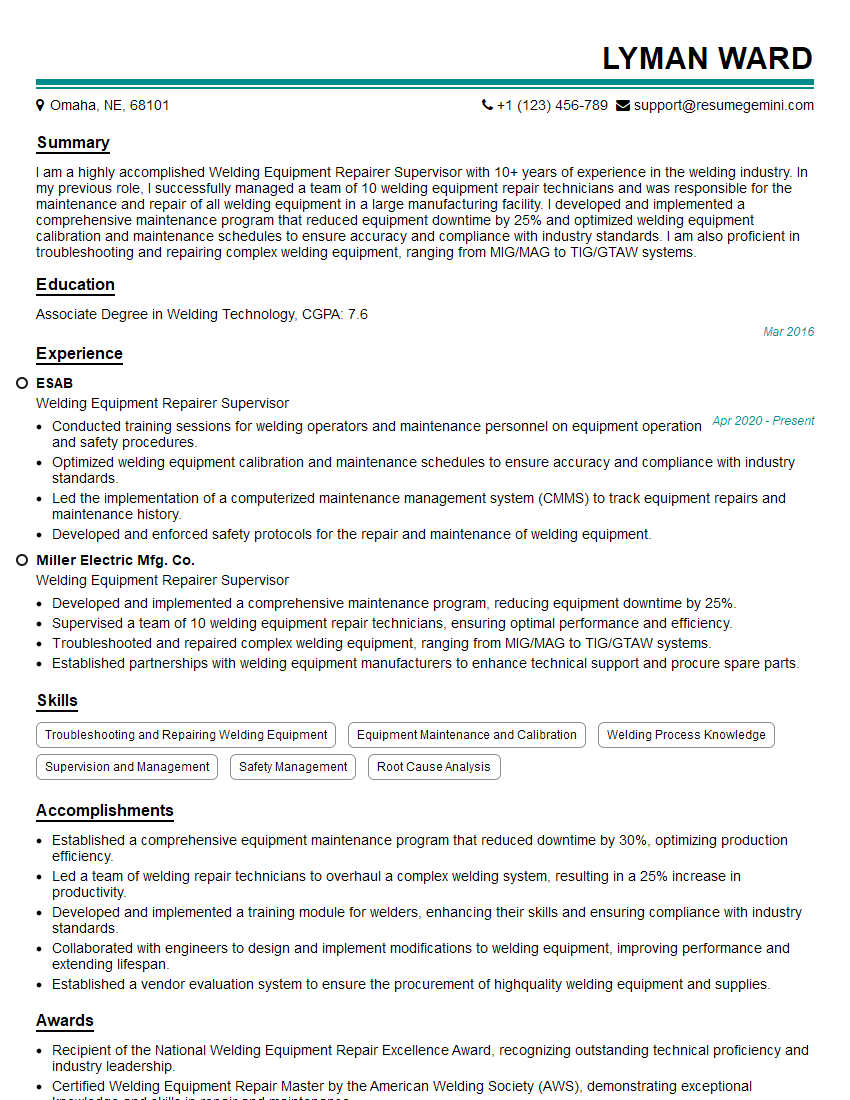

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Equipment Repairer Supervisor

1. Describe the process of troubleshooting a welding equipment malfunction.

- Begin by gathering information about the problem, including the symptoms and any error codes.

- Inspect the equipment for any loose or damaged connections, wires, or components.

- Test the equipment using a multimeter or other diagnostic tools to identify the faulty component.

- Replace or repair the faulty component and reassemble the equipment.

- Conduct a final test to ensure that the equipment is functioning properly.

2. Explain the different types of welding equipment and their applications.

Gas Metal Arc Welding (GMAW)

- Versatile process suitable for a wide range of materials, including steel, aluminum, and stainless steel.

- Uses a shielding gas to protect the weld from contamination.

Gas Tungsten Arc Welding (GTAW)

- Precision welding process that produces high-quality welds.

- Uses a tungsten electrode and a shielding gas.

- Suitable for welding thin materials and critical components.

Shielded Metal Arc Welding (SMAW)

- Simple and inexpensive welding process.

- Uses a covered electrode that melts and creates a protective slag over the weld.

- Suitable for welding thick materials and outdoor applications.

3. Discuss the safety precautions that must be taken when working with welding equipment.

- Wear appropriate protective gear, including gloves, eye protection, and a welding helmet.

- Work in a well-ventilated area to avoid exposure to welding fumes.

- Ground the welding equipment properly to prevent electrical shock.

- Handle hot equipment with care and allow it to cool before touching it with bare hands.

- Store welding equipment and materials safely to prevent accidents.

4. Describe the skills and knowledge required to be a successful Welding Equipment Repairer Supervisor.

- In-depth knowledge of welding equipment and repair procedures.

- Strong troubleshooting and diagnostic skills.

- Ability to read and interpret technical drawings and schematics.

- Excellent communication and interpersonal skills.

- Supervisory and leadership experience.

5. Explain how you would manage a team of Welding Equipment Repairers.

- Set clear expectations and goals for the team.

- Provide training and support to ensure the team is performing at their best.

- Monitor the team’s progress and provide feedback.

- Address any issues or concerns promptly and fairly.

- Promote a positive and supportive work environment.

6. Discuss the latest advancements in welding equipment technology.

- Advanced welding robots that automate welding processes, improving efficiency and accuracy.

- Laser welding technology that offers precise and high-speed welding.

- Virtual reality training simulators that provide immersive training experiences for welders.

- Wireless welding helmets that offer increased safety and comfort for welders.

7. Explain how you stay up-to-date with the latest welding equipment and repair techniques.

- Attend industry conferences and exhibitions.

- Read trade publications and online resources.

- Consult with equipment manufacturers and suppliers.

- Engage in continuing education programs.

8. Describe a challenging welding equipment repair experience and how you overcame it.

- Provide a specific example of a complex repair.

- Explain the steps you took to diagnose and troubleshoot the problem.

- Describe how you used your skills and knowledge to find a solution.

- Discuss the outcome of the repair and what you learned from the experience.

9. What are your strengths and weaknesses as a Welding Equipment Repairer Supervisor?

Strengths

- Excellent troubleshooting and diagnostic skills.

- Strong leadership and management abilities.

- Commitment to safety and quality.

Weaknesses

- Limited experience with certain types of welding equipment.

- Working in high-stress environments.

10. Why are you interested in this position and what makes you a good fit for our company?

- Express enthusiasm for the position and the company’s reputation.

- Highlight your relevant skills and experience.

- Explain how your qualifications align with the company’s needs.

- Indicate your commitment to the company’s values and goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Equipment Repairer Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Equipment Repairer Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

As a Welding Equipment Repairer Supervisor, you will be responsible for overseeing and directing a team of welding equipment repairers, ensuring that all equipment is maintained in optimal condition and any repairs are carried out efficiently and safely.

1. Management and Supervision

Establish and implement policies and procedures for the welding equipment repair department.

- Hire, train, and evaluate welding equipment repairers.

- Assign and oversee welding equipment repair projects.

- Monitor welding equipment repairer performance and provide feedback.

2. Technical Expertise

Diagnose and troubleshoot welding equipment problems and determine appropriate repair methods.

- Supervise the repair of welding equipment, including power sources, wire feeders, and torches.

- Ensure that welding equipment meets safety standards and regulations.

- Stay up-to-date on welding equipment technology and repair techniques.

3. Communication and Coordination

Communicate effectively with welding equipment repairers, customers, and other departments.

- Coordinate with customers to schedule repairs and provide updates.

- Liaise with other departments to obtain necessary parts and support.

- Prepare and maintain documentation related to welding equipment repairs.

4. Quality Control

Inspect and test welding equipment after repairs to ensure they meet specifications.

- Establish and maintain quality control standards for welding equipment repairs.

- Monitor the quality of welding equipment repairs and take corrective action as needed.

- Provide training and support to welding equipment repairers to improve repair quality.

Interview Tips

To ace your interview for a Welding Equipment Repairer Supervisor position, follow these tips:

1. Research the Company and Position

Familiarize yourself with the company’s products, services, and industry standing.

- Review the job description thoroughly and identify the key responsibilities and qualifications.

- Prepare specific examples of your experience that demonstrate your ability to meet the requirements of the role.

2. Highlight Your Technical Expertise

Emphasize your knowledge of welding equipment, repair techniques, and safety standards.

- Provide examples of complex welding equipment repairs you have successfully completed.

- Discuss your experience with troubleshooting and diagnosing welding equipment problems.

- Showcase your understanding of welding codes and regulations.

3. Demonstrate Leadership and Management Skills

Convey your ability to lead and motivate a team of welding equipment repairers.

- Describe your experience in supervising and evaluating employees.

- Explain how you establish and maintain a positive and productive work environment.

- Provide examples of your success in implementing new policies and procedures.

4. Emphasize Communication and Customer Service

Highlight your communication and interpersonal skills, particularly with customers.

- Explain how you effectively communicate technical information to non-technical audiences.

- Provide examples of how you have successfully resolved customer issues and built strong relationships.

- Discuss your experience in coordinating with other departments and external vendors.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Equipment Repairer Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.