Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welding Estimator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welding Estimator so you can tailor your answers to impress potential employers.

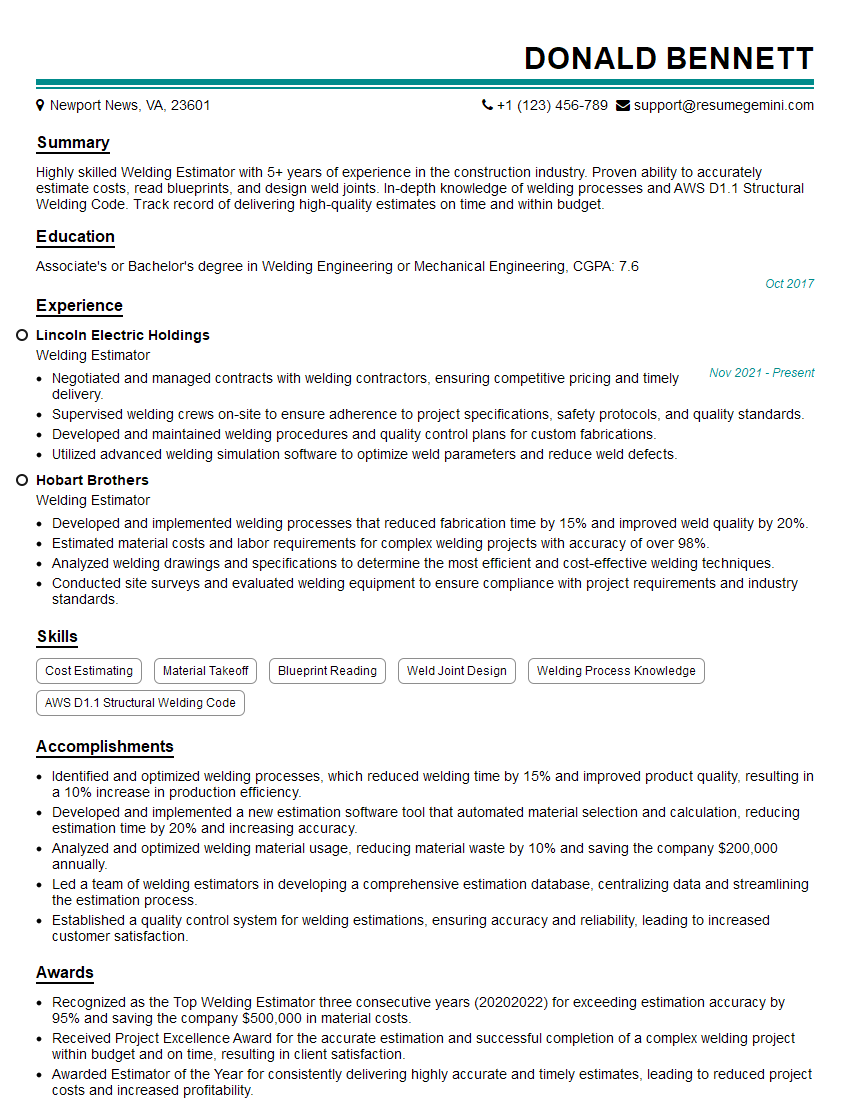

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Estimator

1. What is the difference between MIG and TIG welding?

- MIG (Metal Inert Gas) welding uses a continuously fed wire electrode that is melted by an electric arc and then deposited into the weld joint.

- TIG (Tungsten Inert Gas) welding uses a non-consumable tungsten electrode to create an arc that melts the metal to be joined.

- MIG welding is faster and more versatile than TIG welding, but TIG welding produces higher quality welds.

2. What are the different types of welding joints?

Types of Welding Joints

- Butt Joint: Two pieces of metal are joined together edge-to-edge.

- Edge Joint: Two pieces of metal are joined together by overlapping their edges.

- Corner Joint: Two pieces of metal are joined together at a 90-degree angle.

- T-Joint: A piece of metal is joined to another piece of metal at a 90-degree angle.

Factors to consider when selecting a welding joint

- The strength of the joint

- The appearance of the joint

- The cost of the joint

3. What are the different factors that affect the cost of a welding project?

- The type of welding process

- The materials being welded

- The thickness of the materials

- The size of the project

- The complexity of the project

- The location of the project

4. What are the different types of welding defects?

- Porosity: Small holes or bubbles in the weld metal.

- Slag inclusions: Pieces of slag that are trapped in the weld metal.

- Cold lap: A weld that has not been completely melted together.

- Undercut: A groove that is melted into the base metal next to the weld.

- Overcut: A groove that is melted into the base metal above the weld.

5. What are the different types of welding codes and standards?

- AWS D1.1: Structural Welding Code – Steel

- AWS D1.2: Structural Welding Code – Aluminum

- AWS D1.3: Structural Welding Code – Stainless Steel

- ASME Boiler and Pressure Vessel Code

- API Standard 1104: Welding of Pipelines and Related Facilities

6. What is the difference between a welding procedure and a welding specification?

- A welding procedure is a detailed set of instructions that specifies the welding process, materials, and techniques to be used for a specific welding application.

- A welding specification is a document that defines the requirements for a welded product, including the welding procedure, materials, and quality control.

7. What is the role of a welding engineer?

- Design welding processes and procedures

- Specify welding materials and equipment

- Develop welding quality control programs

- Troubleshoot welding problems

- Supervise welding personnel

8. What is the difference between a welding inspector and a welding engineer?

- A welding inspector is responsible for ensuring that welds meet the requirements of the welding code or specification.

- A welding engineer is responsible for designing welding processes and procedures that meet the requirements of the welding code or specification.

9. What are the different types of welding software?

- Welding simulation software: This software can be used to simulate the welding process and predict the results of different welding parameters.

- Welding design software: This software can be used to design welding joints and calculate the welding parameters.

- Welding inspection software: This software can be used to inspect welds and identify defects.

10. What are the different types of welding automation?

- Manual welding: This is the most common type of welding, in which the welder manually controls the welding torch and the welding process.

- Semi-automatic welding: In this type of welding, the welder controls the welding torch, but the welding process is automated.

- Automatic welding: In this type of welding, the welding process is completely automated.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Estimator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Estimator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Estimators play a crucial role in the welding industry. They are responsible for accurately estimating the cost of welding projects, taking into account factors such as labor, materials, and equipment. This helps ensure that welding projects are completed within budget and on time.

1. Estimate Welding Costs

The primary responsibility of a Welding Estimator is to estimate the cost of welding projects. This involves analyzing project blueprints, specifications, and other relevant documents to determine the scope of the project and the materials and labor required.

- Determine the type of welding required (e.g., MIG, TIG, Arc) and the welding materials needed.

- Estimate the labor hours required for the project, based on the complexity of the weld and the experience of the welders.

2. Negotiate and Finalize Contracts

Once the cost estimate is complete, the Welding Estimator negotiates with clients to finalize the contract. This involves discussing payment terms, delivery schedules, and any other relevant details.

- Explain the cost estimate to clients and answer any questions they may have.

- Negotiate pricing and payment schedules.

3. Manage Projects

In some cases, Welding Estimators also manage welding projects. This involves overseeing the work of welders, ensuring that the project is completed on time and within budget.

- Coordinate with welders and other contractors to ensure smooth project execution.

- Monitor project progress and make adjustments as needed.

4. Stay Up-to-Date on Welding Technologies

The welding industry is constantly evolving, so Welding Estimators must stay up-to-date on the latest welding technologies and best practices. This ensures that they can provide accurate cost estimates and effectively manage welding projects.

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

Interview Tips

To ace a Welding Estimator interview, it is essential to be well-prepared and demonstrate your knowledge and skills. Here are some tips:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific Welding Estimator position. This will help you understand the company’s culture, their welding capabilities, and their target market.

- Visit the company’s website and social media pages.

- Read industry news and articles about the company.

2. Highlight Your Technical Skills

During the interview, be sure to highlight your technical skills and knowledge of welding. This includes your experience with different welding processes, materials, and equipment.

- Provide examples of welding projects you have estimated and the techniques you used.

- Discuss your knowledge of welding codes and standards.

3. Demonstrate Your Negotiation Skills

Negotiation is an important part of a Welding Estimator’s job. In the interview, be prepared to discuss your negotiation experience and how you approach negotiations.

- Explain how you prepare for negotiations and gather information.

- Share examples of successful negotiations you have conducted.

4. Ask Thoughtful Questions

Asking thoughtful questions at the end of the interview shows that you are engaged and interested in the position. It also gives you an opportunity to learn more about the company and the role.

- Ask about the company’s welding equipment and capabilities.

- Inquire about the company’s growth plans and how the Welding Estimator position fits into those plans.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Estimator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Estimator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.