Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welding Instructor position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

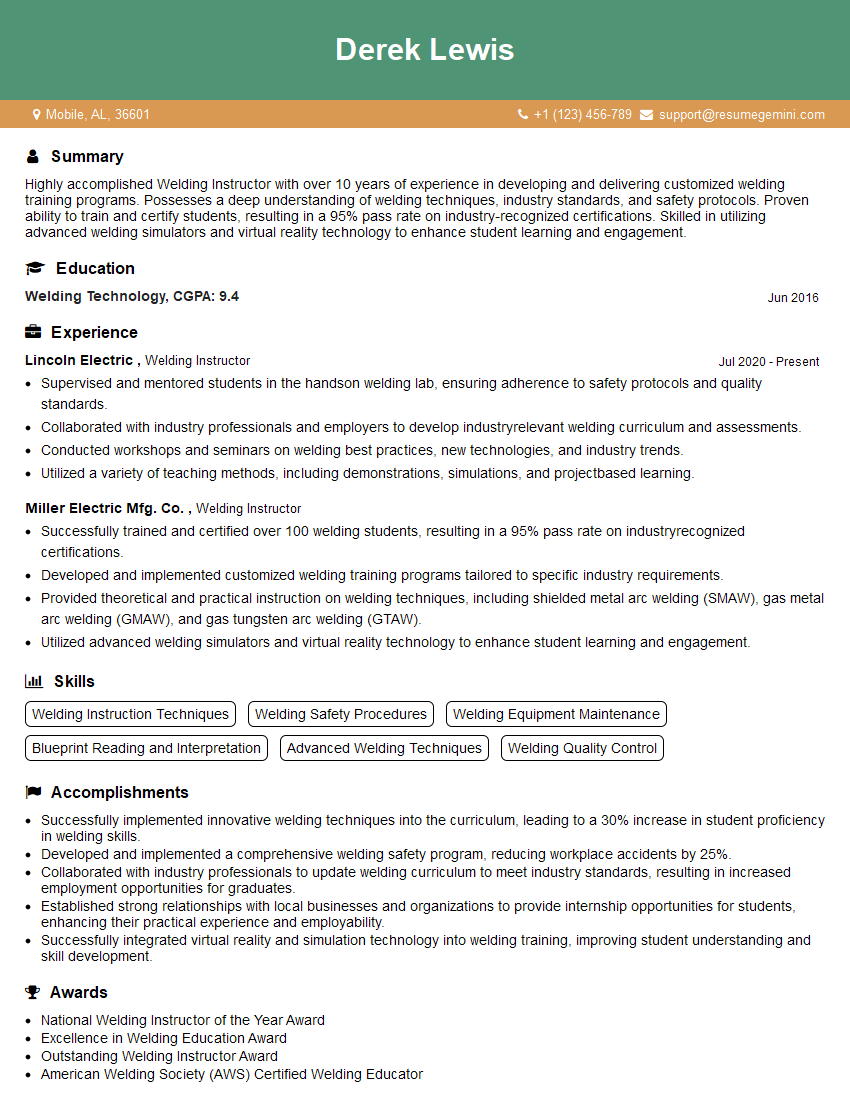

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Instructor

1. Describe the different types of welding processes and their applications?

As a seasoned Welding Instructor, I am well-versed in the diverse array of welding processes, each with its unique applications and advantages. Let me elaborate on the most commonly used techniques:

- Shielded Metal Arc Welding (SMAW), also known as stick welding, is a versatile process suitable for a wide range of metals. It utilizes a consumable electrode that melts and creates an arc, producing a welded joint.

- Gas Metal Arc Welding (GMAW), or MIG welding, employs a continuously fed wire electrode and a shielding gas to protect the weld pool from contamination. This process offers high deposition rates and is commonly used in automotive and manufacturing industries.

- Gas Tungsten Arc Welding (GTAW), or TIG welding, utilizes a non-consumable tungsten electrode and a shielding gas to produce high-quality welds. It is ideal for precision welding of thin materials, such as stainless steel and aluminum.

- Flux-Cored Arc Welding (FCAW) combines the characteristics of SMAW and GMAW. It utilizes a tubular electrode filled with flux, providing shielding and additional alloying elements to the weld.

2. How do you assess and evaluate the quality of a weld?

Visual Inspection

- Examining the weld surface for defects such as cracks, undercuts, and porosity.

- Verifying proper bead size, shape, and penetration.

Destructive Testing

- Tensile Testing: Measuring the weld’s strength by pulling it apart.

- Bend Testing: Evaluating the weld’s ductility by bending it until it fails.

- Impact Testing: Assessing the weld’s toughness by hitting it with a weighted pendulum.

Non-Destructive Testing

- Radiographic Testing (RT): Using X-rays or gamma rays to reveal internal defects.

- Ultrasonic Testing (UT): Utilizing sound waves to detect flaws and measure thickness.

- Magnetic Particle Testing (MT): Applying magnetic particles to highlight surface and near-surface cracks.

3. Explain the importance of safety in welding operations?

Safety is paramount in welding operations to protect both the welder and the surrounding environment. Here are key safety considerations:

- Protective Gear: Wearing appropriate personal protective equipment, including a welding helmet, gloves, and fire-resistant clothing, is essential to prevent exposure to sparks, fumes, and radiation.

- Ventilation: Ensuring adequate ventilation is crucial to remove harmful fumes and gases produced during welding.

- Fire Prevention: Maintaining a clean and organized workspace, using fire extinguishers, and following proper storage guidelines for flammable materials helps prevent fires.

- Electrical Safety: Inspecting equipment regularly, ensuring proper grounding, and following lockout/tagout procedures minimizes electrical hazards.

4. How do you train and certify welding students?

My approach to training and certifying welding students is comprehensive, combining theoretical knowledge with practical hands-on experience:

- Classroom Instruction: Covering welding principles, safety procedures, and industry standards.

- Hands-On Practice: Providing students with ample opportunities to practice various welding techniques under supervision.

- Performance Assessments: Evaluating students’ skills through practical tests and welding qualification exams.

- Industry Certifications: Preparing students for industry-recognized certifications, such as those offered by the American Welding Society (AWS).

5. Describe your experience in developing and implementing welding curricula?

Throughout my career, I have been actively involved in developing and implementing welding curricula that align with industry needs:

- Needs Analysis: Conducting thorough research and gathering feedback from industry professionals to identify current and future skill requirements.

- Curriculum Design: Creating comprehensive curricula that cover essential welding concepts, techniques, and safety protocols.

- Lesson Planning: Developing detailed lesson plans that clearly outline learning objectives, activities, and assessments.

- Implementation and Evaluation: Implementing curricula, monitoring student progress, and making data-driven adjustments to improve effectiveness.

6. How do you stay up-to-date with advancements in welding technology?

Staying current with advancements in welding technology is critical for effective instruction:

- Industry Events: Attending welding conferences, exhibitions, and workshops to learn about new techniques and equipment.

- Professional Development: Participating in continuing education courses and workshops to enhance my knowledge and skills.

- Technical Literature: Reading industry publications, journals, and white papers to keep abreast of the latest research and best practices.

- Networking: Connecting with welding professionals, researchers, and manufacturers to exchange ideas and stay informed about emerging technologies.

7. How do you handle students with different learning styles and abilities?

To cater to students with diverse learning styles and abilities, I employ a flexible and individualized approach:

- Assessment: Assessing students’ learning styles through surveys or observations to tailor my teaching methods.

- Visual Learners: Using visual aids, diagrams, and videos to enhance comprehension.

- Auditory Learners: Incorporating discussions, lectures, and group activities to facilitate learning.

- Kinesthetic Learners: Providing hands-on practice, demonstrations, and simulations to reinforce concepts.

8. Describe your role in managing a welding lab?

As a Welding Instructor, I have successfully managed welding labs, ensuring a safe and productive learning environment:

- Equipment Maintenance: Establishing and implementing regular maintenance schedules for welding equipment.

- Safety Compliance: Enforcing safety protocols, conducting regular inspections, and maintaining a clean and organized workspace.

- Inventory Management: Ordering and managing welding supplies, consumables, and personal protective equipment.

- Student Supervision: Providing guidance, monitoring progress, and ensuring students adhere to safety regulations.

9. How do you promote a positive and collaborative learning environment?

To foster a positive and collaborative learning environment, I implement the following strategies:

- Respectful Interactions: Establishing clear expectations and promoting respectful communication among students and myself.

- Group Projects: Assigning group projects to encourage teamwork and collaboration.

- Peer Feedback: Facilitating peer feedback sessions to provide constructive criticism and support.

- Recognition of Success: Acknowledging and celebrating students’ achievements to build confidence and motivation.

10. How do you assess your own teaching effectiveness?

I continuously assess my teaching effectiveness to identify areas for improvement:

- Student Feedback: Regularly collecting student feedback through surveys or informal discussions.

- Self-Reflection: Observing my teaching practices, identifying strengths and areas for growth.

- Peer Observation: Inviting colleagues to observe my classes and provide constructive feedback.

- Data Analysis: Analyzing student performance data to evaluate the effectiveness of my teaching methods.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Instructor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Instructor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Instructors play a vital role in shaping the skills and knowledge of future welders. Their responsibilities encompass:

1. Instruction and Training

Develop and deliver engaging lesson plans on welding principles, techniques, and safety protocols.

- Demonstrate proper welding techniques while emphasizing safety.

- Supervise students during practical welding exercises, providing guidance and feedback.

2. Assessment and Evaluation

Monitor students’ progress and assess their welding skills through assignments, quizzes, and tests.

- Grade student work and provide constructive feedback to improve their understanding.

- Develop and maintain grading rubrics to ensure fair and consistent assessments.

3. Curriculum Development

Collaborate with other instructors and industry professionals to update and enhance the welding curriculum.

- Research and identify emerging welding technologies and best practices.

- Develop instructional materials and resources to support student learning.

4. Safety Management

Enforce strict safety protocols and maintain a safe learning environment in the welding workshop.

- Conduct regular safety inspections and address any potential hazards.

- Instruct students on proper safety gear, equipment handling, and emergency procedures.

Interview Tips

To ace an interview for a Welding Instructor position, it’s crucial to showcase your expertise, passion, and commitment to student success. Here are some tips:

1. Research and Preparation

Thoroughly research the institution, its welding program, and the specific job description.

- Familiarize yourself with their curriculum, equipment, and any unique features.

- Prepare questions to demonstrate your interest and understanding of the program.

2. Highlight Your Skills and Experience

Emphasize your proficiency in various welding techniques, safety practices, and teaching methodologies.

- Provide specific examples of successful lesson plans, student evaluations, or industry collaborations.

- Discuss your ability to motivate and inspire students to achieve their full potential.

3. Showcase Your Passion and Commitment

Express your enthusiasm for welding and your desire to share your knowledge with others.

- Explain why you believe teaching is your calling and how you make a difference in students’ lives.

- Describe your involvement in professional welding organizations or industry initiatives.

4. Anticipate Common Questions

Prepare for common interview questions related to welding techniques, safety, and instructional methods.

- Practice answering questions about your teaching philosophy and how you handle challenging students.

- Be ready to discuss your plans for integrating new technologies or industry best practices into the curriculum.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Instructor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.