Are you gearing up for an interview for a Welding Lead Burner position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Welding Lead Burner and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

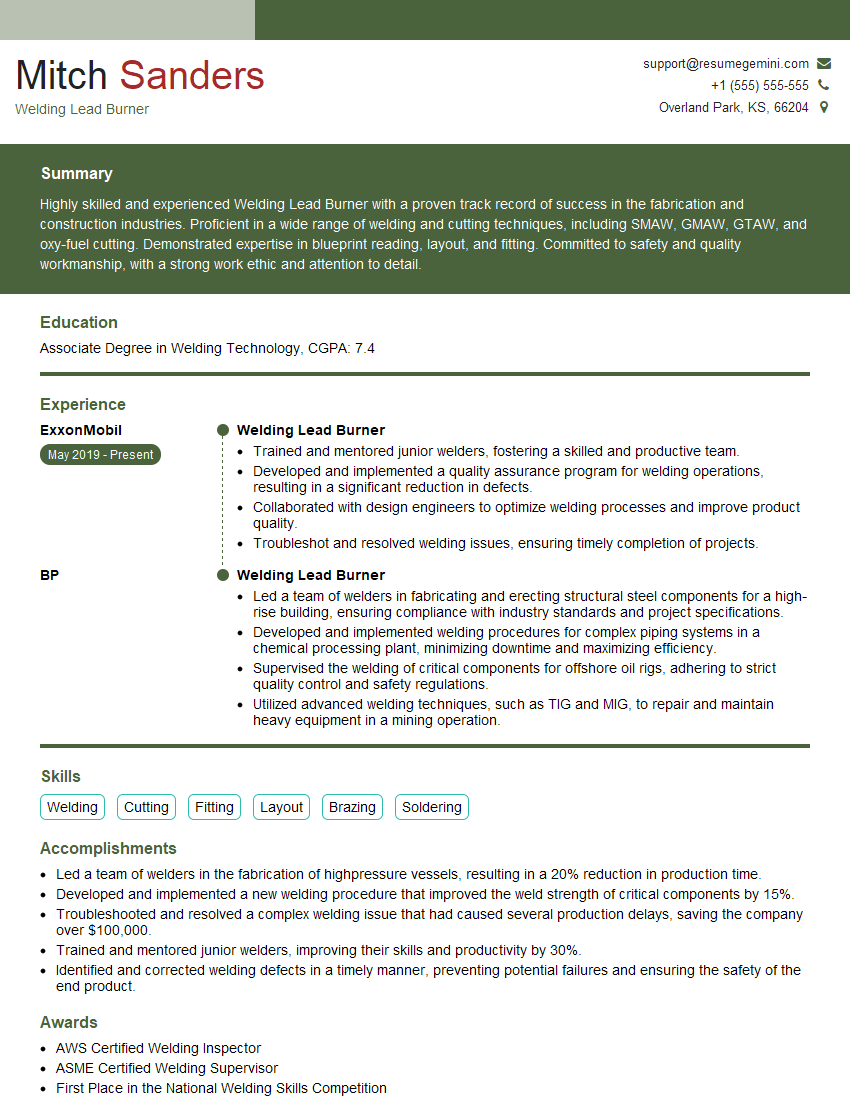

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Lead Burner

1. How do you ensure the quality of your welds?

To ensure the quality of my welds, I follow a strict welding procedure specification (WPS) and adhere to industry standards. I conduct thorough visual inspections of the welds to identify any defects or inconsistencies. I also perform non-destructive testing methods, such as ultrasonic and radiographic testing, to detect internal flaws that may not be visible to the naked eye. By implementing these quality control measures, I can ensure the integrity and reliability of my welds.

2. What are the different types of welding processes you are familiar with?

I am proficient in various welding processes, including:

- Shielded metal arc welding (SMAW)

- Gas tungsten arc welding (GTAW)

- Gas metal arc welding (GMAW)

- Flux-cored arc welding (FCAW)

- Submerged arc welding (SAW)

Each process has its own advantages and applications, and I am well-versed in selecting the appropriate process based on the specific requirements of the project.

3. How do you handle working with different materials?

Working with different materials requires an understanding of their unique properties and characteristics. I have experience welding a wide range of materials, including:

- Steel

- Stainless steel

- Aluminum

- Copper

- Titanium

I adjust my welding techniques and parameters accordingly to achieve optimal results and ensure the longevity of the welded joints.

4. What safety precautions do you take when welding?

Safety is paramount in welding. I strictly adhere to the following safety precautions:

- Wearing appropriate personal protective equipment (PPE), including welding helmet, gloves, and protective clothing

- Ensuring proper ventilation to prevent inhalation of harmful fumes

- Inspecting equipment regularly to ensure it is in good working condition

- Following established safety protocols and procedures

- Being aware of potential hazards and taking steps to mitigate risks

By adhering to these safety precautions, I minimize the risk of accidents and injuries.

5. How do you stay updated on the latest welding techniques and industry best practices?

To stay updated on the latest welding techniques and industry best practices, I:

- Attend industry conferences and seminars

- Read trade publications and technical journals

- Participate in online forums and discussion groups

- Seek guidance from experienced welders and industry experts

- Enroll in continuing education courses and workshops

By continually expanding my knowledge and skills, I ensure that I am utilizing the most effective and efficient welding practices.

6. What are some of the challenges you have faced as a Welding Lead Burner?

One of the challenges I have faced as a Welding Lead Burner is working with intricate and complex structures. These structures require precise welds and attention to detail to ensure structural integrity. I have also encountered situations where the materials being welded have different thicknesses or properties, which necessitates adjusting my techniques and parameters accordingly. Additionally, working in confined spaces or at heights can pose challenges, but I take extra precautions to ensure safety and quality.

7. How do you ensure that your welds meet the required specifications?

To ensure that my welds meet the required specifications, I:

- Thoroughly review the specifications and drawings before starting any work

- Select the appropriate welding process, materials, and equipment for the job

- Perform pre-weld inspections to verify the cleanliness and preparation of the joint

- Follow the welding procedure specification (WPS) and use proper welding techniques

- Conduct post-weld inspections to ensure that the welds meet the required dimensions, strength, and quality standards

By adhering to these steps, I can consistently produce welds that meet or exceed the specified requirements.

8. What is your approach to troubleshooting welding problems?

My approach to troubleshooting welding problems is systematic and methodical:

- First, I identify the symptoms of the problem and gather information about the welding process, materials, and equipment used

- Next, I analyze the possible causes of the problem based on my knowledge and experience

- I then conduct tests or inspections to confirm the root cause of the problem

- Once the root cause is identified, I develop and implement corrective actions to resolve the problem and prevent it from recurring

This approach allows me to quickly and effectively troubleshoot welding problems and ensure the quality of my work.

9. How do you prioritize your tasks and manage your time effectively?

I prioritize my tasks based on their urgency, importance, and deadlines. I use a combination of planning, organization, and time management techniques to ensure that I complete all tasks on time and to a high standard:

- I create a daily or weekly to-do list and break down large tasks into smaller, manageable ones

- I allocate specific time slots for different tasks and stick to the schedule as much as possible

- I minimize distractions and interruptions during work sessions

- I delegate tasks to others when appropriate to optimize efficiency

- I regularly review my progress and make adjustments to my schedule as needed

By effectively managing my time and tasks, I can maximize my productivity and deliver results on schedule.

10. How do you work effectively as part of a team?

I am a highly collaborative and team-oriented individual. I believe that working effectively as part of a team is essential for success in any project. Here are some of the key qualities that I bring to a team environment:

- Excellent communication skills

- Ability to actively listen and understand different perspectives

- Willingness to share knowledge and expertise

- Ability to compromise and find common ground

- Strong work ethic and commitment to team goals

I am confident that I can contribute positively to your team and work effectively with others to achieve the best possible results.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Lead Burner.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Lead Burner‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Lead Burners are skilled professionals who use specialized equipment to join metal components. Their responsibilities include:

1. Welding and Cutting Metals

Using various welding and cutting techniques, such as arc welding, MIG welding, TIG welding, and oxy-fuel cutting.

2. Fabricating and Repairing Metal Structures

Creating and repairing metal components, such as pipes, tanks, and machinery.

3. Reading and Interpreting Technical Drawings

Understanding the specifications and dimensions of the metal structures to be welded or cut.

4. Maintaining Equipment

Ensuring that all welding and cutting equipment is in good working condition.

5. Safety Compliance

Following all safety regulations and guidelines while performing welding and cutting operations.

Interview Tips

To prepare for an interview for a Welding Lead Burner position, consider these tips:

1. Research the Company and Position

Familiarize yourself with the company’s industry, products or services, and the specific requirements of the Welding Lead Burner role.

2. Highlight Your Skills and Experience

Emphasize your welding and cutting abilities, including the specific techniques you are proficient in. Provide examples of projects where you demonstrated your skills.

3. Prepare for Technical Questions

Review common welding and cutting techniques, equipment, and safety procedures. Practice answering questions that assess your technical knowledge.

4. Showcase Your Safety Awareness

Stress the importance of safety in your work and highlight your understanding of industry safety standards and best practices.

5. Practice Communication Skills

Welding Lead Burners often work with engineers, supervisors, and other team members. Demonstrate your ability to communicate effectively and clearly.

6. Dress Professionally

First impressions matter. Dress appropriately for the interview, even if the work environment is casual.

7. Be Enthusiastic and Confident

Convey your passion for welding and your eagerness to contribute to the company’s success.

Next Step:

Now that you’re armed with the knowledge of Welding Lead Burner interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Welding Lead Burner positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini