Feeling lost in a sea of interview questions? Landed that dream interview for Welding Machine Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Welding Machine Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

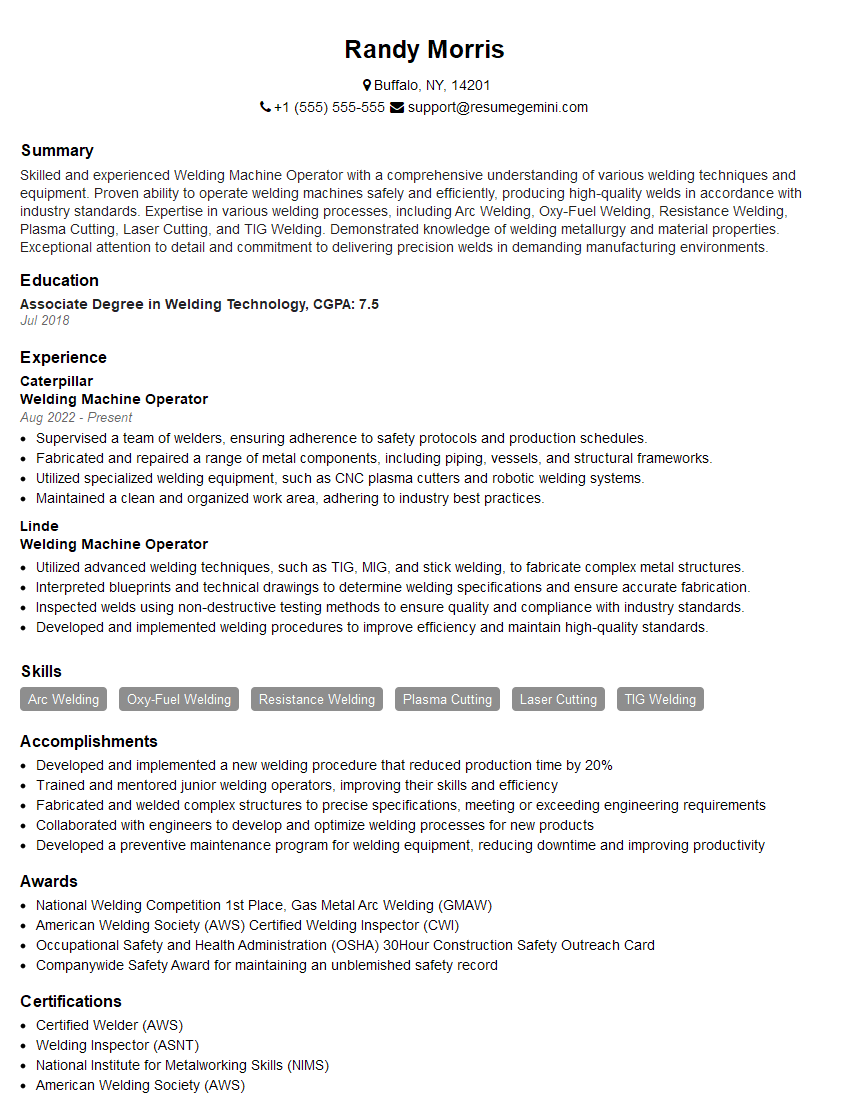

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Machine Operator

1. Explain the different types of welding processes and their applications?

- Arc welding uses an electric arc to melt the metal and create a weld. It is a versatile process that can be used for a variety of metals, and it produces strong, durable welds.

- Gas welding uses a fuel gas, such as acetylene or propane, to heat the metal and create a weld. It is a slower process than arc welding, but it produces high-quality welds.

- Resistance welding uses pressure and heat to create a weld. It is a fast process that is often used for mass production.

- Solid-state welding uses pressure and heat to create a weld without melting the metal. It is a strong and durable process that is often used for joining dissimilar metals.

2. What are the key factors that affect the quality of a weld?

Preparation of the materials

- The surfaces of the materials to be welded must be clean and free of contaminants, such as oil or dirt.

- The edges of the materials must be properly aligned and fitted.

Welding process

- The correct welding process must be selected for the materials and application.

- The welding parameters, such as the heat input and travel speed, must be properly set.

Welder’s skill

- A skilled welder will be able to produce high-quality welds consistently.

- Welders must be trained and certified.

3. What are the most common welding defects and how can they be prevented?

The most common welding defects are:

- Porosity is caused by gas bubbles that are trapped in the weld metal. It can be prevented by using a shielding gas to protect the weld from the atmosphere.

- Inclusions are foreign objects that are trapped in the weld metal. They can be prevented by cleaning the materials to be welded and by using a shielding gas.

- Cracking is caused by the weld metal cooling too quickly or by the presence of impurities. It can be prevented by preheating the materials to be welded and by using a slow cooling rate.

- Undercut is caused by the weld metal not penetrating completely into the base metal. It can be prevented by using a higher heat input.

- Overcut is caused by the weld metal penetrating too deeply into the base metal. It can be prevented by using a lower heat input.

4. What are the different types of welding equipment and their uses?

- Arc welding machines are used to create an electric arc between the welding electrode and the base metal. They can be used for a variety of welding processes, including SMAW, GMAW, and GTAW.

- Gas welding equipment includes a torch, a fuel gas, and a shielding gas. It is used for gas welding and brazing.

- Resistance welding machines use pressure and heat to create a weld. They are often used for mass production.

- Solid-state welding machines use pressure and heat to create a weld without melting the metal. They are often used for joining dissimilar metals.

5. What are the safety precautions that must be taken when welding?

- Wear appropriate personal protective equipment, including a welding helmet, gloves, and clothing.

- Ensure that the welding area is well-ventilated.

- Use a fire extinguisher to protect against fire.

- Be aware of the hazards of welding fumes and gases.

- Follow all safety procedures and guidelines.

6. What are the different types of welding joints and their strengths?

- Butt joint is a joint where the edges of the two pieces of metal are aligned and welded together.

- Edge joint is a joint where the edges of the two pieces of metal are overlapped and welded together.

- Corner joint is a joint where the two pieces of metal are joined at a right angle and welded together.

- T-joint is a joint where one piece of metal is perpendicular to the other and welded together.

- Lap joint is a joint where one piece of metal overlaps the other and welded together.

7. What are the different types of welding consumables and their uses?

- Welding electrodes are used to create an electric arc between the welding electrode and the base metal. They are made of a variety of materials, including steel, stainless steel, and aluminum.

- Welding wire is used for GMAW and GTAW welding. It is made of a variety of materials, including steel, stainless steel, and aluminum.

- Welding flux is used to protect the weld from the atmosphere. It is made of a variety of materials, including borax, fluorspar, and silica.

- Welding gas is used to protect the weld from the atmosphere. It is made of a variety of gases, including argon, helium, and carbon dioxide.

8. What are the different types of welding techniques and their applications?

- SMAW (Shielded Metal Arc Welding) is a manual welding process that uses a consumable electrode to create an electric arc between the electrode and the base metal.

- GMAW (Gas Metal Arc Welding) is a semi-automatic welding process that uses a consumable wire electrode to create an electric arc between the electrode and the base metal.

- GTAW (Gas Tungsten Arc Welding) is a manual welding process that uses a non-consumable tungsten electrode to create an electric arc between the electrode and the base metal.

- FCAW (Flux-Cored Arc Welding) is a semi-automatic welding process that uses a consumable wire electrode that contains flux.

- SAW (Submerged Arc Welding) is a semi-automatic welding process that uses a consumable wire electrode and a granular flux that is submerged in the weld area.

9. What are the different types of welding codes and standards?

- AWS D1.1 is a welding code that is used for structural steel welding.

- AWS D1.2 is a welding code that is used for stainless steel welding.

- AWS D1.3 is a welding code that is used for aluminum welding.

- ASME Boiler and Pressure Vessel Code is a welding code that is used for the fabrication of boilers and pressure vessels.

- API 1104 is a welding code that is used for the fabrication of pipelines.

10. What is the future of welding?

- Automated welding is becoming increasingly popular, as it can improve productivity and quality.

- New welding technologies are being developed all the time, such as laser welding and plasma welding.

- The welding industry is constantly evolving, and new innovations are always being made.

- Welding is a vital part of the manufacturing industry, and it is expected to continue to grow in the future.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Machine Operators play a crucial role in manufacturing and construction industries by operating welding machines to join and repair metal components. Their key job responsibilities include:

1. Welding and Assembly

Operate welding machines to join metal components using specific welding techniques such as MIG, TIG, or arc welding.

- Interpret blueprints and welding specifications to ensure accuracy and quality control.

- Assemble and position metal pieces for welding, using jigs, fixtures, or hand tools.

2. Quality Control

Inspect welds visually or using testing equipment to ensure they meet specified standards for strength and appearance.

- Make necessary adjustments to welding parameters or techniques to achieve optimal weld quality.

- Maintain and calibrate welding equipment to ensure consistent and accurate welding performance.

3. Maintenance and Repair

Perform scheduled maintenance and minor repairs on welding equipment to prevent breakdowns and maintain optimal efficiency.

- Troubleshoot and resolve welding problems to minimize downtime and production delays.

- Clean and maintain welding areas, ensuring adherence to safety regulations and best practices.

4. Safety Compliance

Prioritize workplace safety by adhering to established safety protocols and wearing appropriate protective gear.

- Ensure compliance with industry regulations and best practices related to welding operations.

- Follow emergency procedures and respond effectively to accidents or incidents.

Interview Tips

Preparing thoroughly for a job interview is essential for showcasing your skills and making a positive impression on the hiring manager.

1. Research the Company and Role

Research the company’s website, industry news, and social media platforms to gain insights into their culture, values, and current projects.

- Review the job description thoroughly to understand the specific requirements and qualifications for the Welding Machine Operator role.

- Identify areas where your skills and experience align with the job responsibilities.

2. Practice Common Interview Questions

Anticipate common interview questions related to your welding experience, technical skills, and workplace behavior.

- Prepare thoughtful answers that highlight your strengths, qualifications, and enthusiasm for the role.

- Consider using the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific examples of your accomplishments.

3. Showcase Your Technical Skills

Emphasize your proficiency in welding techniques, equipment operation, and quality control procedures.

- Quantify your experience by providing specific numbers and metrics that demonstrate your productivity and efficiency.

- Be prepared to discuss different types of welding techniques, materials, and welding equipment.

4. Highlight Your Safety Awareness

Welding involves potential hazards, so interviewers will assess your safety consciousness and adherence to industry regulations.

- Demonstrate your understanding of workplace safety protocols, including the use of personal protective equipment (PPE).

- Emphasize your commitment to maintaining a clean and organized work environment.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.