Feeling lost in a sea of interview questions? Landed that dream interview for Welding Machine Operator/Tender but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Welding Machine Operator/Tender interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

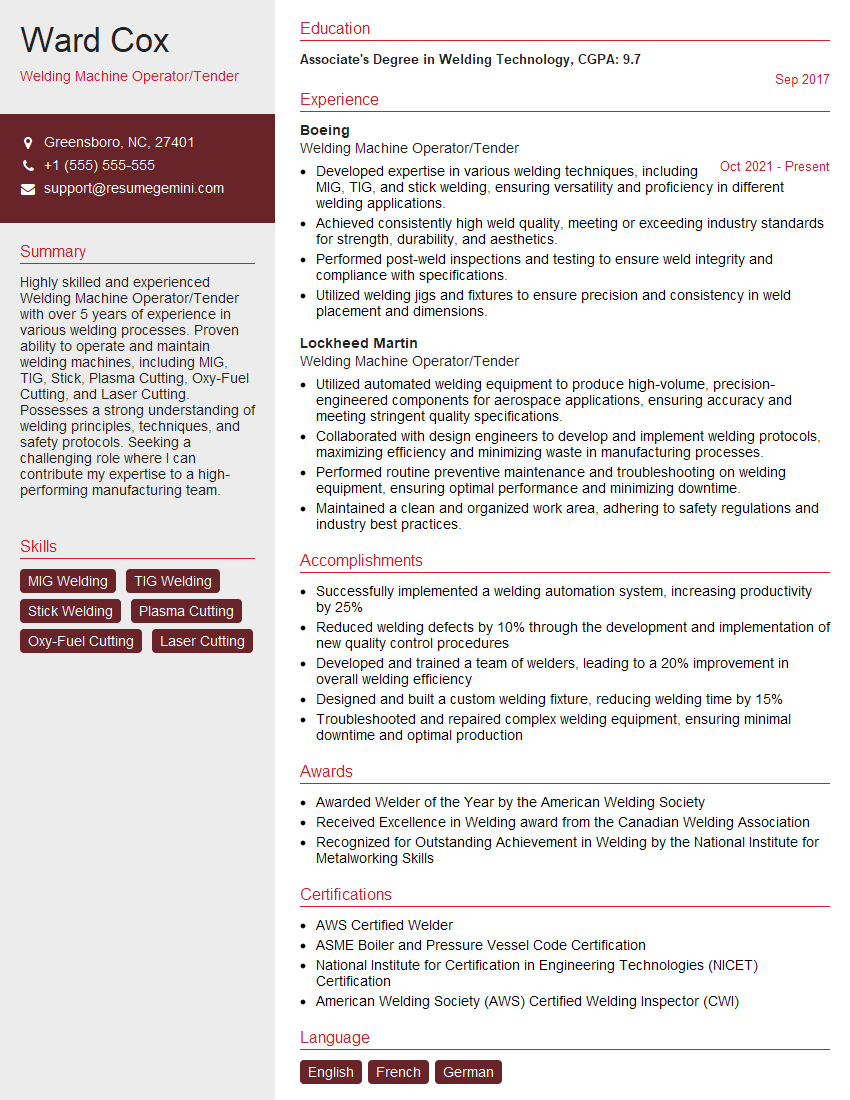

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Machine Operator/Tender

1. Can you explain the different types of welding processes and their applications?

There are several welding processes, including:

- Arc Welding: Uses an electric arc to melt the metal and fuse the workpiece. It includes MIG, TIG, and Stick welding.

- Resistance Welding: Involves applying pressure and heat from electrodes to join metals without melting them. Types include Spot Welding and Seam Welding.

- Gas Welding: Uses a fuel gas and oxygen to create a flame for melting metals. Common types are Oxy-Acetylene Welding and Oxy-Fuel Welding.

- Plasma Arc Welding: Employs a plasma torch to produce a high-temperature plasma that melts the metal and shields it from contamination.

2. Describe the welding techniques you are proficient in and provide examples of where you have used them.

MIG Welding

- Used for welding thin to medium-thickness metals, such as steel, aluminum, and stainless steel.

- Examples: Automotive body panels, sheet metal components, and welding pipes and tubes.

TIG Welding

- Suitable for precision welding of thin metals and materials requiring high-quality welds, such as stainless steel, aluminum, and titanium.

- Examples: Aerospace components, medical equipment, and delicate machinery.

3. How do you determine the correct welding parameters (e.g., voltage, amperage, travel speed) based on the material and thickness?

Determining welding parameters involves considering factors such as:

- Material Thickness: Thicker materials require higher amperage and voltage.

- Material Type: Different materials have varying thermal conductivity and weldability, affecting the parameters.

- Joint Design: Welds with deep penetration require higher amperage, while shallow welds need lower amperage.

- Welding Process: Each process has specific parameters based on the equipment and consumables used.

4. What are the common welding defects and how do you prevent them?

- Porosity: Prevent by using clean materials, ensuring proper shielding gas flow, and avoiding excessive heat.

- Undercut: Ensure joint preparation is clean and free of rust, and adjust welding parameters to avoid excessive penetration.

- Cold Laps: Avoid excessive travel speed, ensure proper heat input, and maintain a clean weld joint.

- Cracks: Use preheating and post-heating techniques to reduce thermal stresses, and select appropriate filler metals.

5. How do you maintain and calibrate welding equipment to ensure optimal performance?

- Regular cleaning and inspection of welding equipment to prevent malfunctions.

- Calibration of welding machines according to manufacturer’s specifications using certified equipment.

- Ensuring proper maintenance of gas cylinders, regulators, and hoses to maintain correct flow rates and pressures.

- Following safety protocols and wearing appropriate personal protective equipment.

6. What safety precautions should be taken when operating welding equipment?

- Wear appropriate personal protective equipment, including safety glasses, welding helmet, gloves, and protective clothing.

- Ensure proper ventilation and smoke extraction to prevent exposure to harmful fumes.

- Handle welding equipment with care, including proper storage and handling of gas cylinders.

- Follow established safety protocols and procedures to minimize risks and accidents.

7. How do you interpret welding symbols and follow welding procedures?

Interpreting welding symbols involves understanding the:

- Type of weld joint (e.g., square, bevel, edge)

- Weld size and dimensions

- Welding process and additional specifications

Following welding procedures includes:

- Adhering to specified weld parameters, such as voltage, amperage, and travel speed.

- Using the correct welding consumables, including electrodes, filler metals, and shielding gases.

- Maintaining proper joint preparation and assembly techniques.

8. What is the difference between preheating and post-heating in welding?

- Preheating: Involves heating the workpiece before welding to reduce the risk of cracking, especially for thick or high-strength materials.

- Post-heating: Performed after welding to allow the weldment to cool slowly, reducing internal stresses and improving material properties.

9. Describe the different types of welding joints and their applications.

- Butt Joint: Used to join two pieces of metal end-to-end.

- Edge Joint: Similar to a butt joint, but the edges of the metal are joined instead of the ends.

- Corner Joint: Used to join two pieces of metal at a 90-degree angle.

- T-Joint: Used to join two pieces of metal where one piece is perpendicular to the other.

10. What are the key considerations for selecting the appropriate welding process for a given application?

- Material Type and Thickness

- Joint Design and Configuration

- Quality and Strength Requirements

- Available Equipment and Resources

- Cost and Efficiency

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Machine Operator/Tender.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Machine Operator/Tender‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Machine Operators/Tenders play a crucial role in the manufacturing industry, handling the operation and maintenance of welding machines. They are responsible for ensuring the efficient and safe production of welded components.

1. Machine Operation

Operators are tasked with the setup and operation of various welding machines, including MIG, TIG, and robotic systems.

- Configure and adjust machine parameters (e.g., voltage, speed, gas flow).

- Load and secure workpieces into welding fixtures.

- Monitor welding processes to ensure quality and accuracy.

2. Quality Control

Operators conduct visual inspections of welded joints to assess their quality.

- Check for defects such as porosity, undercut, and burn-through.

- Measure and record dimensions to ensure compliance with specifications.

- Maintain records of inspections and repairs.

3. Maintenance and Repair

Operators perform routine maintenance and minor repairs on welding machines.

- Clean and lubricate machine components.

- Replace worn or damaged parts.

- Calibrate and adjust machines to maintain optimal performance.

4. Safety and Compliance

Operators follow established safety protocols and adhere to industry standards.

- Wear appropriate personal protective equipment (e.g., gloves, goggles, welding helmet).

- Maintain a clean and organized work area.

- Comply with environmental regulations and welding safety guidelines.

Interview Tips

To ace the interview for a Welding Machine Operator/Tender position, candidates should:

1. Research the Company and Role

Familiarize yourself with the company’s industry, products, and specific requirements for the role. This shows your interest and preparedness.

- Visit the company website and social media pages.

- Review the job description thoroughly.

2. Highlight Your Skills and Experience

Emphasize your technical skills, certifications, and experience that align with the job responsibilities. Quantify your accomplishments whenever possible.

- Example: “In my previous role, I exceeded quality standards by monitoring welding processes and achieving a defect rate of less than 0.5%.”

3. Prepare for Technical Questions

Expect questions about welding equipment, techniques, and safety. Practice answering these questions clearly and concisely.

- Example: “Describe the difference between MIG and TIG welding and when each is appropriate.”

4. Emphasize Safety and Compliance

Demonstrate your understanding of welding safety protocols and industry regulations. Show that you prioritize safety in your work.

- Example: “I am trained in arc flash prevention and follow all OSHA safety guidelines while operating welding machines.”

5. Prepare for Behavioral Questions

Interviewers may ask behavioral questions to assess your teamwork, problem-solving, and communication skills. Use the STAR method (Situation, Task, Action, Result) to provide clear and concise answers.

- Example: “Tell me about a time you faced a challenging welding issue. How did you approach it and what was the outcome?”

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Welding Machine Operator/Tender role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.