Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welding Pantograph Machine Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welding Pantograph Machine Operator so you can tailor your answers to impress potential employers.

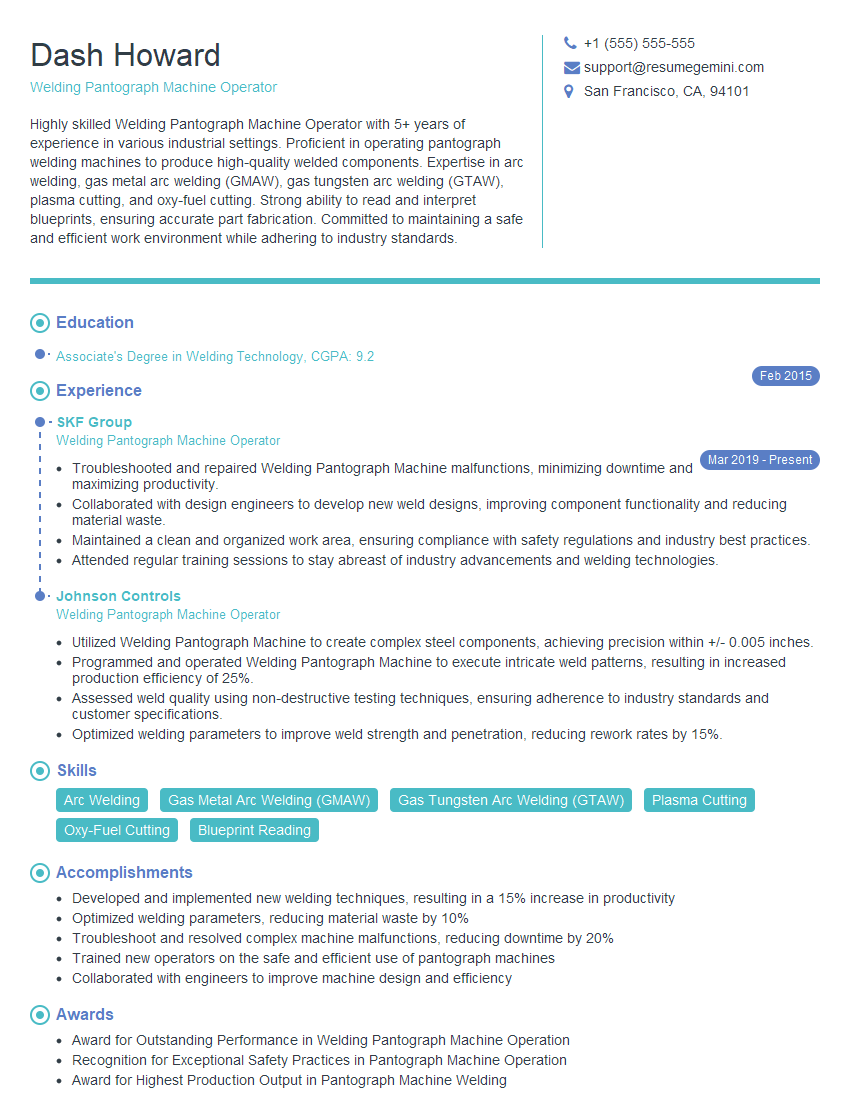

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Pantograph Machine Operator

1. What are the different types of welding processes used with a pantograph machine?

- Shielded metal arc welding (SMAW)

- Gas metal arc welding (GMAW)

- Gas tungsten arc welding (GTAW)

- Flux-cored arc welding (FCAW)

2. How do you ensure the accuracy and quality of welds made with a pantograph machine?

Setup and Calibration

- Calibrate the machine regularly to ensure precise movement and alignment.

- Properly set up the welding torch and adjust the welding parameters.

Monitoring and Adjustment

- Continuously monitor the welding process and make adjustments as needed.

- Inspect welds visually and using non-destructive testing methods to verify quality.

3. What are the safety precautions you take when operating a pantograph welding machine?

- Wear appropriate personal protective equipment (PPE), including welding helmet, gloves, and protective clothing.

- Ensure the machine is properly grounded and the welding area is well-ventilated.

- Handle welding gases and consumables safely.

- Follow established safety protocols and procedures.

4. How do you troubleshoot common problems with a pantograph welding machine?

- Identify the problem and isolate the cause.

- Check electrical connections, gas flow, and welding consumables.

- Adjust welding parameters or reconfigure the machine setup.

- Consult technical manuals or seek assistance from experienced technicians.

5. What preventive maintenance tasks are important for a pantograph welding machine?

- Regularly clean and lubricate moving parts.

- Inspect and replace worn or damaged components.

- Check electrical connections and ensure proper grounding.

- Schedule regular maintenance with qualified technicians.

6. How do you interpret welding blueprints and specifications?

- Read and understand weld symbols and abbreviations.

- Identify welding materials, joint designs, and welding parameters.

- Determine the sequence and orientation of welds.

- Apply engineering principles to interpret and execute welding instructions.

7. What is your experience with programming and operating CNC pantograph welding machines?

- Describe the programming software and CNC controls you have used.

- Explain how you create and edit welding programs.

- Discuss your experience in optimizing welding parameters and achieving high-quality welds.

8. How do you handle variations in material thickness and welding conditions?

- Identify and compensate for differences in material properties.

- Adjust welding parameters, such as wire feed speed, travel speed, and heat input.

- Use specialized techniques, such as step welding or weaving, to accommodate variations.

9. What are the key factors that affect the quality and strength of welded joints?

- Joint preparation and cleanliness

- Welding process and parameters

- Filler metal selection and quality

- Shielding gas composition

- Operator skill and experience

10. How do you stay up-to-date with the latest advancements in welding technology?

- Attend industry conferences and workshops.

- Read technical journals and articles.

- Seek training and certifications from recognized organizations.

- Collaborate with other welding professionals and share knowledge.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Pantograph Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Pantograph Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Welding Pantograph Machine Operator is responsible for operating and maintaining welding pantograph machines used in the manufacturing of various metal products.

1. Machine Operation

The operator is responsible for setting up, calibrating, and operating welding pantograph machines according to specifications.

- Follows work orders, blueprints, and welding procedures

- Selects and installs welding tips and electrodes

- Adjusts machine settings, such as speed, temperature, and pressure

2. Troubleshooting and Maintenance

The operator is responsible for troubleshooting and performing basic maintenance on welding pantograph machines to ensure optimal performance.

- Identifies and resolves machine malfunctions

- Performs routine maintenance tasks, such as cleaning and lubrication

- Reports any major issues or repairs to supervisors

3. Quality Control

The operator is responsible for ensuring the quality of welded products by following established quality standards.

- Inspects welded products for defects

- Makes adjustments to machine settings as needed

- Maintains records of welding parameters and quality control checks

4. Safety

The operator is responsible for adhering to all safety regulations and guidelines while operating welding pantograph machines.

- Wears appropriate personal protective equipment (PPE)

- Follows established safety protocols

- Reports any unsafe conditions or practices

Interview Tips

To ace an interview for a Welding Pantograph Machine Operator position, it is important to be well-prepared and demonstrate your knowledge, skills, and experience.

1. Research the Company and Position

Before the interview, take the time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and specific requirements for the role.

- Visit the company’s website to learn about their products, services, and history.

- Read online reviews and articles about the company to get insights into their reputation and employee experience.

- Review the job description carefully to identify the key responsibilities and qualifications required for the position.

2. Highlight Your Relevant Skills and Experience

During the interview, be sure to highlight your relevant skills and experience that align with the requirements of the position. Quantify your accomplishments using specific examples and metrics.

- Discuss your experience operating and maintaining welding pantograph machines, including the types of machines you have used.

- Provide examples of how you have successfully resolved machine malfunctions and ensured the quality of welded products.

- Emphasize your knowledge of welding procedures, safety protocols, and quality control standards.

3. Prepare for Technical Questions

Be prepared to answer technical questions related to welding pantograph machines and welding techniques. This may include questions about:

- The principles of welding and the different types of welding processes.

- The operation and maintenance of welding pantograph machines.

- Troubleshooting common machine malfunctions and performing basic maintenance tasks.

4. Practice Your Answers and Dress Professionally

Before the interview, practice answering common interview questions and prepare thoughtful questions to ask the interviewer. Dress professionally and arrive on time for your interview to demonstrate your attention to detail and respect for the opportunity.

- Prepare for questions about your motivation for applying for the position and your career goals.

- Dress in clean, pressed clothing that is appropriate for a professional setting.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Pantograph Machine Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Pantograph Machine Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.