Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Welding Pantograph Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

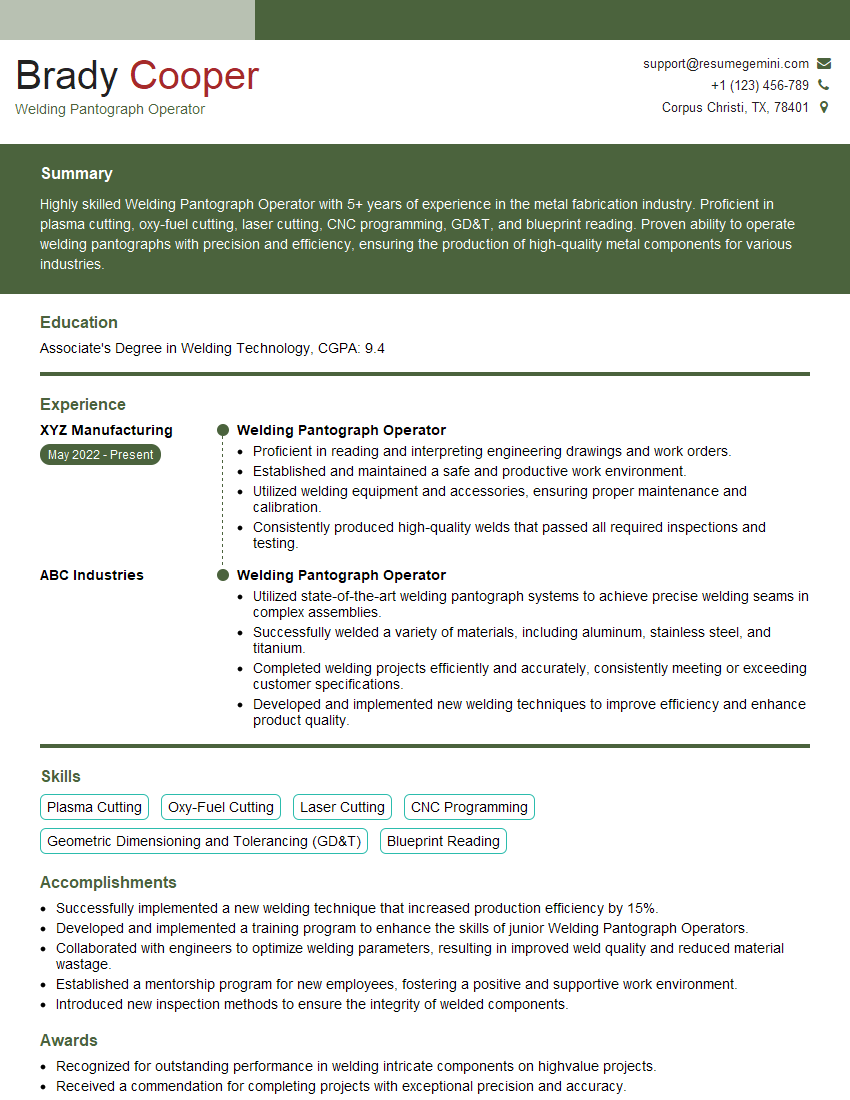

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Pantograph Operator

1. Describe the different types of welding pantographs you have used and their respective applications?

As a Welding Pantograph Operator, I have experience with various types of welding pantographs, each tailored to specific applications. Here are some examples:

- Manual Pantograph: Used for manual welding operations, allowing for precise control and flexibility during complex welding tasks.

- Semi-Automatic Pantograph: Employs a CNC controller to guide the welding torch, combining automation with manual intervention for increased efficiency and accuracy.

- Fully-Automatic Pantograph: Highly automated system that follows pre-programmed welding paths, ensuring consistent and high-quality welds.

2. Explain the principles and techniques involved in welding using a pantograph?

Proper Setup and Calibration:

- Ensuring that the pantograph is accurately calibrated to the welding machine and the workpiece to achieve precise and consistent welding results.

- Setting up the welding parameters, such as welding speed, wire feed rate, and gas flow, to optimize the welding process.

Welding Techniques:

- Understanding different welding techniques, such as pulsed welding and continuous welding, to suit the specific requirements of the project.

- Maintaining proper torch angle and travel speed to achieve optimal weld quality and penetration.

3. Discuss the safety precautions to be followed when operating a welding pantograph?

- Wearing appropriate personal protective equipment (PPE), including welding helmet, gloves, and protective clothing, to safeguard against hazards.

- Ensuring proper ventilation in the work area to minimize exposure to welding fumes and gases.

- Following established safety protocols, such as lockout/tagout procedures, to prevent accidents and injuries.

4. Describe the process of troubleshooting common issues encountered when operating a welding pantograph?

Troubleshooting welding pantograph issues requires a systematic approach:

- Inspection: Visually examining the pantograph, welding machine, and workpiece to identify potential problems.

- Diagnosis: Using technical knowledge and experience to determine the root cause of the issue, such as misalignment, electrical faults, or gas flow problems.

- Resolution: Implementing corrective actions, such as adjusting settings, replacing components, or re-calibrating the system, to resolve the issue.

5. Explain the importance of regular maintenance and calibration of a welding pantograph?

- Ensuring the accuracy and precision of the pantograph, leading to consistent and high-quality welding results.

- Preventing breakdowns and downtime by identifying potential problems early on and addressing them promptly.

- Extending the lifespan of the pantograph and reducing overall maintenance costs.

6. Describe the quality control measures employed to ensure the quality of welds produced using a welding pantograph?

- Visual Inspection: Examining welds for any visible defects, such as porosity, cracks, or undercut.

- Non-Destructive Testing (NDT): Using techniques like ultrasonic testing or radiography to detect internal flaws in the welds.

- Destructive Testing: Conducting tests, such as bend tests or tensile tests, to evaluate the strength and integrity of the welds.

7. Explain the role of software in the operation and programming of a welding pantograph?

- Programming: Using software to create welding programs that define the welding parameters and path for the pantograph.

- Simulation: Simulating welding operations using software to optimize the welding process and prevent errors.

- Monitoring and Control: Employing software to monitor and control the pantograph’s operation during welding, ensuring precision and accuracy.

8. Discuss the advantages and disadvantages of using a welding pantograph compared to manual welding?

Advantages:

- Precision and Accuracy: Pantographs offer precise control over welding parameters and path, resulting in consistent and high-quality welds.

- Increased Efficiency: Automation reduces production time, leading to improved efficiency and productivity.

- Reduced Labor Costs: Pantographs reduce the need for skilled welders, potentially lowering labor costs.

Disadvantages:

- High Initial Investment: Pantographs can be expensive to purchase and set up.

- Limited Flexibility: Pantographs are less flexible than manual welding, requiring reprogramming for different welding tasks.

- Maintenance and Calibration: Pantographs require regular maintenance and calibration to ensure optimal performance.

9. Describe your experience in working with different materials and thicknesses using a welding pantograph?

I have experience in welding various materials and thicknesses using a welding pantograph:

- Materials: Mild steel, stainless steel, aluminum, and titanium.

- Thicknesses: Ranging from thin sheets to thick plates, adapting welding parameters and techniques accordingly.

10. Explain how you would approach welding a complex or large workpiece using a welding pantograph?

- Planning: Carefully reviewing the workpiece design and identifying potential challenges.

- Setup: Ensuring proper setup of the pantograph, workpiece, and welding machine.

- Programming: Creating a detailed welding program that takes into account the workpiece geometry and welding requirements.

- Execution: Executing the welding program with precision, monitoring the process closely.

- Quality Control: Conducting quality checks throughout the welding process to ensure the integrity of the welds.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Pantograph Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Pantograph Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Pantograph Operators are responsible for operating and maintaining welding pantographs, which are specialized machines used to weld metal components together. Key job responsibilities include:

1. Operating Welding Pantographs

Operate welding pantographs to weld metal components according to specifications.

- Set up and adjust welding parameters, such as speed, amperage, and voltage.

- Monitor welding process and make adjustments as needed.

2. Maintaining Welding Pantographs

Perform routine maintenance on welding pantographs, including cleaning, lubrication, and replacement of worn parts.

- Inspect welding pantographs for damage or malfunction.

- Troubleshoot and repair welding pantographs.

3. Quality Control

Inspect welded components to ensure they meet quality standards.

- Verify dimensions and tolerances of welded components.

- Identify and correct defects in welded components.

4. Safety

Follow all safety protocols and procedures.

- Wear appropriate personal protective equipment (PPE).

- Maintain a clean and organized work area.

Interview Tips

To prepare for an interview for a Welding Pantograph Operator position, candidates should consider the following tips:

1. Research the Company and Position

Familiarize yourself with the company’s website, industry news, and the specific requirements of the Welding Pantograph Operator position.

- Identify the company’s products or services and their market position.

- Highlight any experience or skills that align with the specific requirements of the job.

2. Practice Your Skills

Review your welding knowledge and practice operating welding pantographs if possible. This will help you demonstrate your proficiency and confidence during the interview.

- Set up a welding pantograph and practice making welds on different types of metal.

- Review welding safety protocols and procedures.

3. Prepare Questions for the Interviewer

Prepare thoughtful questions to ask the interviewer. This shows your interest in the position and the company.

- Inquire about the company’s growth plans and industry trends.

- Ask about the specific responsibilities and expectations of the Welding Pantograph Operator role.

4. Be Enthusiastic and Positive

Convey your enthusiasm for welding and your desire to contribute to the company. A positive attitude can make a lasting impression.

- Express your passion for welding and your commitment to quality.

- Share any relevant experiences or projects that demonstrate your skills and abilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Welding Pantograph Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.