Are you gearing up for a career in Welding Setter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Welding Setter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

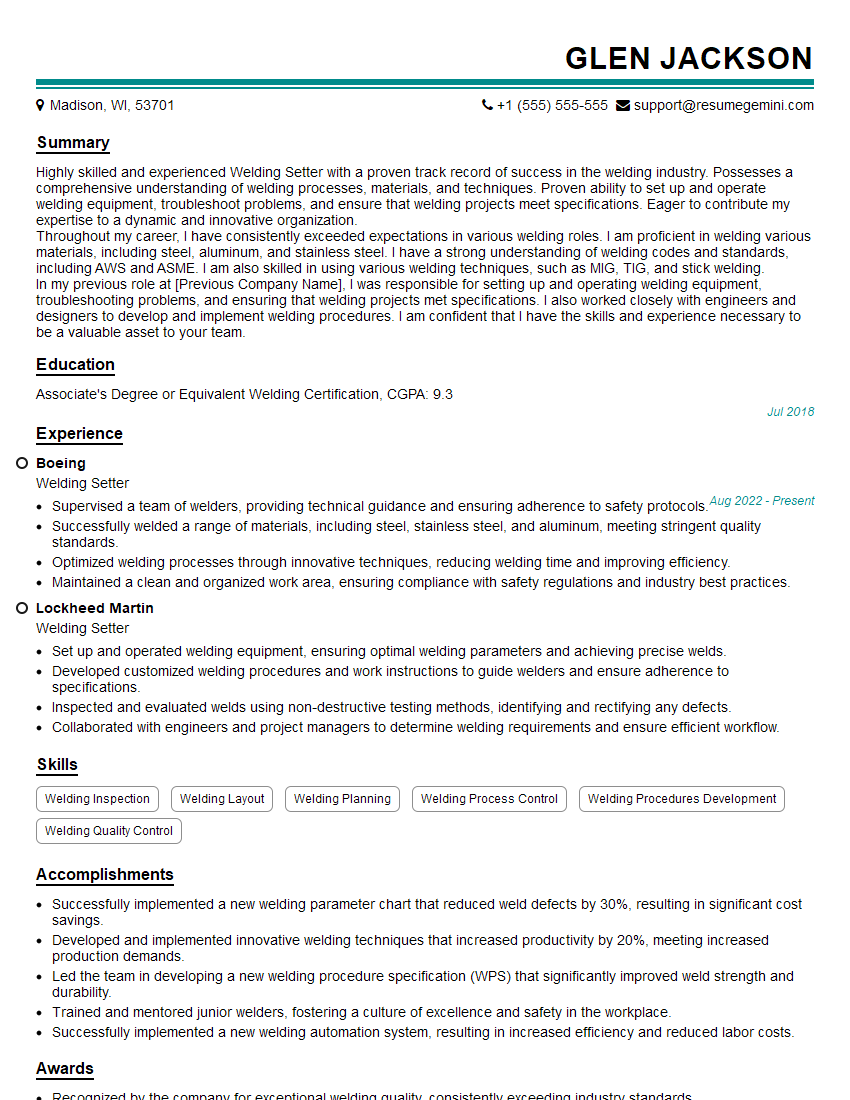

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Setter

1. What are the Different Welding Joints?

- Butt joint: Used to join two pieces of metal together in a straight line.

- Edge joint: Used to join two pieces of metal together along their edges.

- T-joint: Used to join two pieces of metal together at a right angle.

- Lap joint: Used to join two pieces of metal together by overlapping them.

- Corner joint: Used to join two pieces of metal together at a 90-degree angle.

2. What is the Difference Between Flux-Cored Arc Welding (FCAW) and Gas Metal Arc Welding (GMAW)?

FCAW

- Uses a continuous wire electrode that is filled with flux.

- The flux melts and forms a protective atmosphere around the weld area.

- FCAW is typically used for welding thicker metals.

GMAW

- Uses a continuous wire electrode that is not filled with flux.

- A separate shielding gas is used to protect the weld area.

- GMAW is typically used for welding thinner metals.

3. What are the Different Types of Welding Defects?

- Porosity: Caused by gas bubbles that become trapped in the weld metal.

- Lack of fusion: Occurs when the weld metal does not properly fuse to the base metal.

- Undercut: A groove that is formed along the edge of the weld where the weld metal has melted away the base metal.

- Overcut: A groove that is formed along the edge of the weld where the weld metal has melted away too much of the base metal.

- Cracking: A fracture that occurs in the weld metal or the base metal.

4. What are the Different Types of Welding Equipment?

- Welding machine: Provides the electrical power for the welding process.

- Welding torch: Directs the welding arc to the weld area.

- Welding wire: The consumable material that is melted to form the weld.

- Shielding gas: Protects the weld area from the atmosphere.

- Safety gear: Protects the welder from the hazards of welding, such as fumes, UV radiation, and molten metal.

5. What are the Different Welding Techniques?

- Stick welding: Uses a consumable electrode that is coated with flux.

- MIG welding: Uses a continuous wire electrode that is fed through a welding gun.

- TIG welding: Uses a non-consumable tungsten electrode and a separate shielding gas.

- Plasma arc welding: Uses a plasma torch to create a high-energy arc.

- Laser welding: Uses a laser to melt the metal and form a weld.

6. What is the Importance of Joint Preparation?

- Ensures that the weld joint is clean and free of contaminants.

- Prevents weld defects, such as lack of fusion and porosity.

- Improves the appearance of the weld joint.

- Reduces the amount of time and materials required to weld the joint.

7. What are the Different Types of Welding Codes and Standards?

- AWS D1.1: Structural Welding Code – Steel.

- AWS D1.2: Structural Welding Code – Aluminum.

- AWS D1.3: Structural Welding Code – Stainless Steel.

- ASME Boiler and Pressure Vessel Code: Used for the design and construction of boilers and pressure vessels.

- API Standards: Used for the design and construction of oil and gas pipelines.

8. What is the Importance of Welding Safety?

- Protects the welder from injuries, such as burns, eye damage, and respiratory problems.

- Prevents fires and explosions.

- Ensures the quality of the weld joint.

- Reduces the overall cost of welding.

9. What are the Different Types of Welding Careers?

- Welder: Performs the actual welding of metal components.

- Welding engineer: Designs and develops welding processes and equipment.

- Welding inspector: Ensures that welds meet the required codes and standards.

- Welding sales representative: Sells welding equipment and supplies.

- Welding instructor: Teaches welding skills to new welders.

10. What is the Future of Welding?

- Increased automation: Robots and other automated systems will be used more and more to perform welding tasks.

- New welding technologies: New welding technologies, such as laser welding and electron beam welding, are being developed and will become more common in the future.

- Increased demand for welders: The demand for welders is expected to grow in the future as more and more industries rely on welding to manufacture their products.

- Increased focus on welding safety: There will be an increased focus on welding safety in the future as more and more companies recognize the importance of protecting their welders from injuries.

- Welder training: Welder training will become more important in the future as new welding technologies are developed and the demand for welders grows.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Setter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Setter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Setters are responsible for setting up and maintaining welding equipment and ensuring that welds meet the required standards. They must have a strong understanding of welding techniques and materials, as well as the ability to read and interpret technical drawings and specifications.

1. Equipment Setup and Maintenance

Welding Setters are responsible for setting up and maintaining welding equipment, such as welding machines, torches, and plasma cutters. They must ensure that the equipment is calibrated and functioning properly, and that all safety precautions are followed.

- Install, calibrate, and maintain welding equipment

- Troubleshoot and repair welding equipment

2. Welding Techniques

Welding Setters must have a strong understanding of welding techniques, such as arc welding, MIG welding, and TIG welding. They must be able to select the appropriate technique for the job and use it safely and effectively.

- Select and apply welding techniques based on material type and thickness

- Monitor and control welding parameters, such as speed, amperage, and voltage

3. Quality Control

Welding Setters are responsible for ensuring that welds meet the required standards. They must inspect welds for defects and ensure that they are strong and durable. They must also be able to record and report any welding problems or defects.

- Inspect welds for defects and non-conformances

- Document and report welding problems or defects

4. Safety

Welding Setters must follow all safety precautions when working with welding equipment. They must wear appropriate protective clothing and equipment, and they must be aware of the potential hazards of welding.

- Follow all safety precautions when working with welding equipment

- Wear appropriate protective clothing and equipment

Interview Tips

To ace an interview for a Welding Setter position, it is important to be well-prepared. Here are some tips:

1. Research the Company and the Position

Before the interview, take some time to research the company and the position. This will help you understand the company’s culture and the specific requirements of the job. You can also use this research to prepare questions to ask the interviewer.

- Visit the company’s website

- Read articles about the company

- Talk to people who work at the company

2. Practice Your Answers to Common Interview Questions

There are a number of common interview questions that you are likely to be asked. It is helpful to practice your answers to these questions in advance so that you can feel confident and prepared during the interview.

- Tell me about your experience with welding.

- What are your strengths and weaknesses as a welder?

- Why do you want to work for this company?

3. Bring a Portfolio of Your Work

If you have a portfolio of your welding work, bring it to the interview. This will give the interviewer a chance to see your skills and craftsmanship firsthand.

4. Dress Professionally

First impressions matter, so it is important to dress professionally for the interview. This means wearing clean, pressed clothes and shoes. You should also avoid wearing any jewelry or clothing that could be a safety hazard.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Setter, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Setter positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.