Are you gearing up for a career in Welding Specialist? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Welding Specialist and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

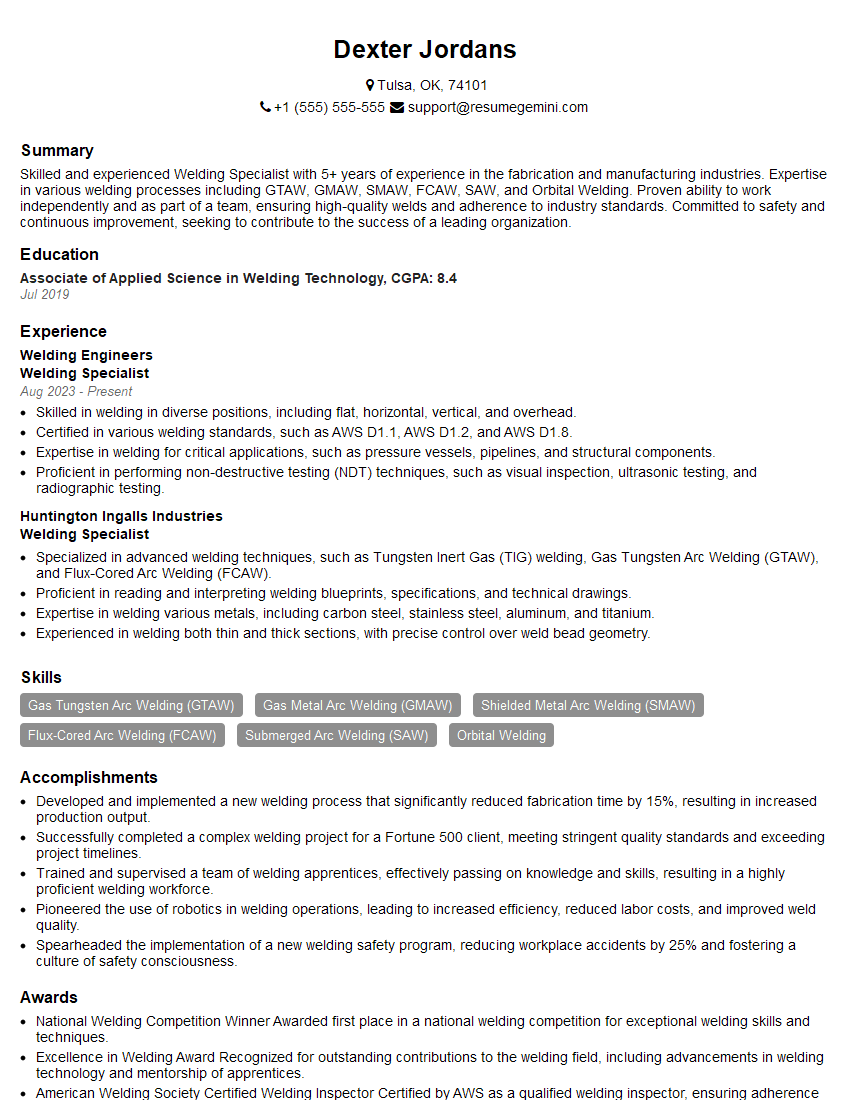

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Specialist

1. What are the different types of welding processes and which one would you recommend for a particular application?

There are many different types of welding processes, each with its own advantages and disadvantages. The most common types of welding processes are:

- Arc welding

- Gas welding

- Resistance welding

- Solid-state welding

The best welding process for a particular application will depend on a number of factors, including the type of materials being welded, the thickness of the materials, and the desired strength of the weld.

2. What are the safety precautions that need to be taken when welding?

Fire safety

- Wear appropriate protective clothing, including a welding helmet, gloves, and apron.

- Keep the work area clean and free of flammable materials.

- Have a fire extinguisher nearby.

Electrical safety

- Inspect welding equipment regularly for damage.

- Use insulated tools and wear rubber gloves when working on electrical equipment.

- Never touch live electrical wires.

Respiratory safety

- Use a respirator when welding in enclosed areas.

- Ventilate the work area to remove welding fumes.

- Avoid breathing in welding fumes.

3. What are the different types of welding joints?

There are many different types of welding joints, each with its own advantages and disadvantages. The most common types of welding joints are:

- Butt joint

- Edge joint

- T-joint

- Corner joint

- Lap joint

The best welding joint for a particular application will depend on a number of factors, including the type of materials being welded, the thickness of the materials, and the desired strength of the weld.

4. What are the different types of welding defects?

There are many different types of welding defects, each with its own causes and consequences. The most common types of welding defects are:

- Porosity

- Slag inclusions

- Incomplete fusion

- Undercut

- Cracking

Welding defects can be prevented by following proper welding procedures and by using high-quality welding materials.

5. What are the different types of welding equipment?

There are many different types of welding equipment, each with its own advantages and disadvantages. The most common types of welding equipment are:

- Welding machines

- Welding torches

- Welding rods

- Welding wire

- Welding helmets

- Welding gloves

- Welding aprons

The best welding equipment for a particular application will depend on the type of welding being performed, the materials being welded, and the desired quality of the weld.

6. What are the different types of welding codes and standards?

There are many different types of welding codes and standards, each with its own purpose and scope. The most common types of welding codes and standards are:

- American Welding Society (AWS) codes and standards

- American Society of Mechanical Engineers (ASME) codes and standards

- International Organization for Standardization (ISO) codes and standards

- Canadian Standards Association (CSA) codes and standards

- British Standards Institution (BSI) codes and standards

Welding codes and standards are important because they provide guidelines for the design, fabrication, and inspection of welded structures. By following welding codes and standards, you can help to ensure that your welded structures are safe and reliable.

7. What are the different types of welding certifications?

There are many different types of welding certifications, each with its own requirements and scope. The most common types of welding certifications are:

- American Welding Society (AWS) certifications

- American Society of Mechanical Engineers (ASME) certifications

- International Organization for Standardization (ISO) certifications

- Canadian Standards Association (CSA) certifications

- British Standards Institution (BSI) certifications

Welding certifications are important because they demonstrate that you have the skills and knowledge to perform welding tasks safely and effectively. By obtaining welding certifications, you can increase your earning potential and improve your job prospects.

8. What are the latest trends in welding technology?

The welding industry is constantly evolving, with new technologies being developed all the time. Some of the latest trends in welding technology include:

- The use of robots for welding

- The development of new welding processes, such as laser welding and friction welding

- The use of new welding materials, such as high-strength steels and aluminum alloys

- The development of new welding equipment, such as portable welding machines and welding helmets with built-in cameras

These new technologies are making welding faster, more efficient, and more precise than ever before.

9. What are the challenges facing the welding industry?

The welding industry is facing a number of challenges, including:

- The shortage of skilled welders

- The increasing cost of welding materials

- The competition from foreign manufacturers

- The need to meet increasingly stringent environmental regulations

These challenges are making it difficult for welding companies to compete and stay profitable.

10. What are the opportunities for the welding industry?

Despite the challenges, there are also a number of opportunities for the welding industry. These include:

- The growing demand for welding in the construction, manufacturing, and energy industries

- The development of new welding technologies

- The increasing use of welding in the repair and maintenance of infrastructure

- The growing awareness of the importance of welding safety

These opportunities are creating new jobs and new markets for the welding industry.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Specialist.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Specialist‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Specialists are responsible for performing a variety of welding tasks, ensuring the quality and safety of welded structures. Their key responsibilities include:

1. Welding and Fabrication

Performing various types of welding, including arc, oxy-fuel, and MIG/TIG welding.

- Fabricating and assembling metal components according to specifications and drawings.

- Maintaining and repairing welded structures and equipment.

2. Quality Control and Inspection

Inspecting welds to ensure they meet quality standards and safety codes.

- Conducting destructive and non-destructive testing to evaluate weld integrity.

- Maintaining records and documentation related to welding activities.

3. Equipment Maintenance

Maintaining and calibrating welding equipment to ensure optimal performance.

- Troubleshooting and resolving equipment malfunctions.

- Following safety protocols and adhering to established procedures.

4. Collaboration and Communication

Collaborating with engineers, designers, and other technicians to ensure project completion.

- Providing input on welding techniques and material selection.

- Communicating effectively with clients and stakeholders.

Interview Tips

To ace your Welding Specialist interview, consider the following preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and services.

- Stay up-to-date on industry trends and welding technologies.

- Demonstrate your interest and knowledge of the field.

2. Showcase Your Technical Skills

Emphasize your expertise in various welding techniques and equipment.

- Quantify your experience with specific projects and accomplishments.

- Provide examples of your ability to troubleshoot and solve problems.

3. Highlight Your Safety Awareness

Welding involves potential hazards, so interviewers value safety consciousness.

- Demonstrate your understanding of workplace safety protocols.

- Describe your experience in adhering to safety regulations and preventing accidents.

4. Prepare for Specific Questions

Anticipate common interview questions and prepare thoughtful responses tailored to the job description.

- Review welding terminology and industry standards.

- Practice describing your approach to quality control and ensuring structural integrity.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Specialist, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Specialist positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.