Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Welding Tester interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Welding Tester so you can tailor your answers to impress potential employers.

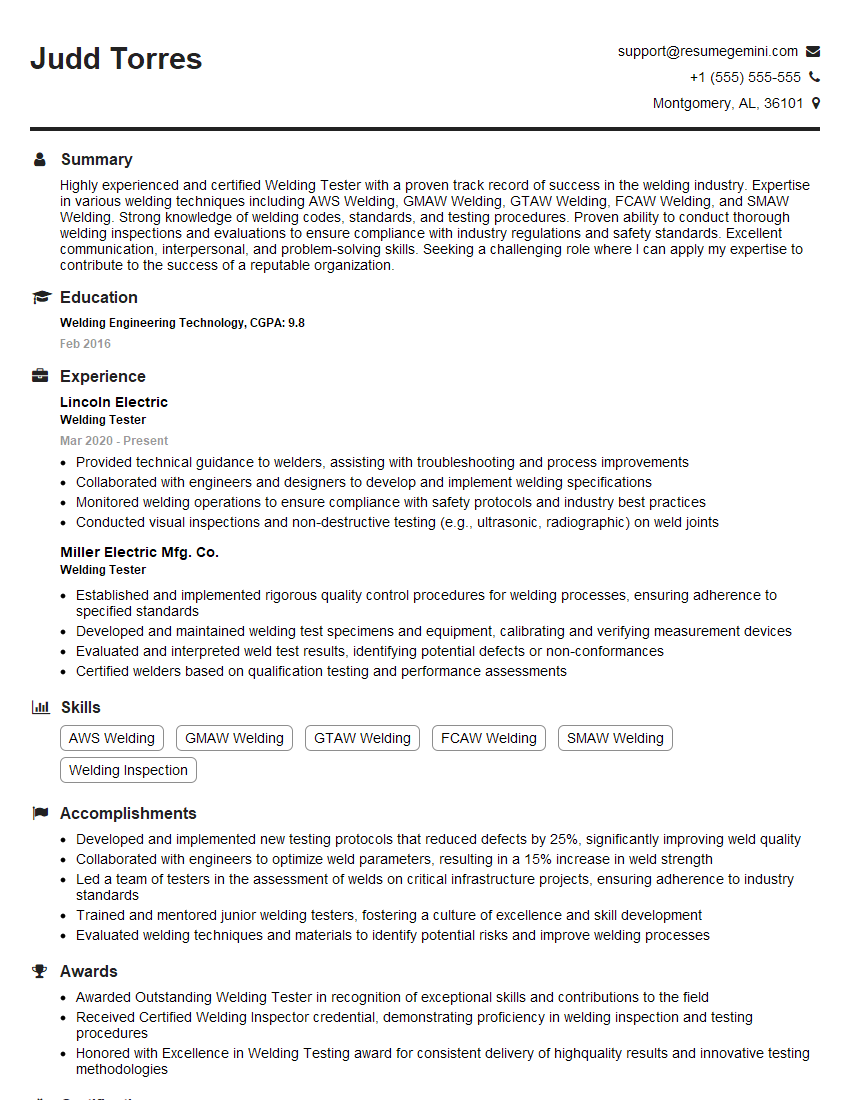

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Welding Tester

1. What are the different types of welding processes and their applications?

- Shielded metal arc welding (SMAW): This is a manual welding process that uses a covered electrode. It is commonly used for welding mild steel and low-alloy steels.

- Gas metal arc welding (GMAW): This is a semi-automatic or automatic welding process that uses a consumable wire electrode and a shielding gas.

- Gas tungsten arc welding (GTAW): This is a manual welding process that uses a non-consumable tungsten electrode and a shielding gas.

- Plasma arc welding (PAW): This is a high-energy welding process that uses a plasma arc to melt the metal.

- Laser beam welding (LBW): This is a high-power laser beam to weld materials.

2. What are the different types of weld defects and how can they be prevented?

Weld porosity

- Cause: Entrapment of gas during welding

- Prevention: Use dry welding consumables, clean the weld area, and use an appropriate welding technique.

Incomplete fusion

- Cause: Insufficient heat input during welding

- Prevention: Increase the welding heat input, use a larger electrode, or use a different welding process.

Undercut

- Cause: Excessive welding heat input or improper welding technique

- Prevention: Reduce the welding heat input, use a smaller electrode, or use a different welding process.

Cracking

- Cause: High stresses during welding or cooling

- Prevention: Preheat the weld area, use a lower welding heat input, or use a different welding process.

3. What are the different types of welding codes and standards?

- American Welding Society (AWS)

- American Society of Mechanical Engineers (ASME)

- American Petroleum Institute (API)

- International Organization for Standardization (ISO)

4. What are the different types of welding equipment and how are they used?

- Welding machines: These machines provide the electrical power for welding.

- Welding torches: These devices direct the welding arc and shielding gas to the weld area.

- Welding consumables: These materials include electrodes, wire, and shielding gases.

- Welding accessories: These items include welding helmets, gloves, and safety glasses.

5. What are the safety precautions that must be taken when welding?

- Wear appropriate personal protective equipment (PPE), such as a welding helmet, gloves, and safety glasses.

- Ensure that the welding area is well-ventilated.

- Keep flammable materials away from the welding area.

- Do not weld on live electrical circuits.

- Be aware of the potential for fire and explosion.

6. What is the difference between a welder and a welding tester?

- Welders are responsible for joining materials together using a welding process.

- Welding testers are responsible for inspecting welds to ensure that they meet quality standards.

7. What are the different types of welding tests and how are they performed?

- Visual inspection: This is a non-destructive test that is used to examine the surface of a weld for defects.

- Radiographic testing (RT): This is a non-destructive test that is used to examine the interior of a weld for defects.

- Ultrasonic testing (UT): This is a non-destructive test that is used to examine the interior of a weld for defects using sound waves.

- Magnetic particle testing (MT): This is a non-destructive test that is used to examine the surface of a weld for cracks.

- Dye penetrant testing (PT): This is a non-destructive test that is used to examine the surface of a weld for cracks.

8. What are the different factors that can affect the quality of a weld?

- Welding process

- Welding equipment

- Welding consumables

- Welding technique

- Environmental conditions

9. What are the different ways to improve the quality of a weld?

- Use a welding process that is appropriate for the materials being welded.

- Use welding equipment that is in good condition.

- Use welding consumables that are of high quality.

- Use a welding technique that is appropriate for the materials and welding process being used.

- Ensure that the welding area is clean and free of contaminants.

10. What is the future of welding?

- The use of robotics and automation in welding is expected to increase.

- New welding technologies, such as laser beam welding and plasma arc welding, are being developed.

- The use of welding in new industries, such as the automotive and aerospace industries, is expected to grow.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Welding Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Welding Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Welding Testers are responsible for ensuring the quality of welds in various industries, including construction, manufacturing, and automotive. They play a crucial role in maintaining the safety and integrity of welded structures and components.

1. Welding Inspection and Testing

Conduct visual inspections and non-destructive testing (NDT) techniques, such as radiography, ultrasonic testing, and magnetic particle testing, to evaluate weld quality

- Interpret test results and report any defects or deviations from specifications

- Document inspection findings and maintain detailed records

2. Code and Standard Compliance

Ensure that welding processes and procedures adhere to industry standards and codes, such as AWS, ASME, and API

- Monitor welding operations and provide guidance to welders

- Stay up-to-date on changes in codes and standards

3. Weld Procedure Qualification

Qualify welding procedures and welders through standardized testing and evaluation

- Develop and implement weld procedure specifications (WPS)

- Conduct welder performance qualification tests (WPQT)

4. Quality Control and Assurance

Monitor and control the quality of welding processes and products

- Identify and address potential quality issues

- Implement corrective actions to prevent defects and improve weld quality

Interview Tips

Preparing for an interview for a Welding Tester position requires thorough understanding of the job responsibilities and strong technical knowledge. Here are some tips to help you ace your interview:

1. Research the Company and Role

Before the interview, take time to research the company and the specific role you are applying for. Learn about their industry, products, and quality standards. This knowledge will help you tailor your answers to the interviewer’s questions and demonstrate your interest in the position.

- Visit the company website and read news articles

- Review the job description carefully

2. Highlight Technical Skills and Knowledge

The interviewer will be looking for candidates with a strong foundation in welding theory, inspection techniques, and industry codes. Be prepared to discuss your knowledge of welding processes, NDT methods, and the relevant standards.

- Provide specific examples of welding inspections and tests you have conducted

- Showcase your understanding of welding metallurgy and weld defects

3. Emphasize Quality and Safety

Welding Testers play a critical role in ensuring the quality and safety of welded structures. In your interview, emphasize your commitment to quality and safety. Highlight your experience in implementing quality control measures and your knowledge of industry regulations.

- Describe your approach to weld inspection and how you ensure accurate and reliable results

- Discuss your experience in developing and implementing welding procedure specifications (WPS)

4. Communicate Clearly and Professionally

Welding Testers must be able to communicate clearly and professionally with welders, engineers, and management. Be prepared to demonstrate your ability to interpret technical information and present your findings effectively.

- Practice your communication skills by rehearsing your answers to common interview questions

- Dress professionally and arrive on time for your interview

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Welding Tester, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Welding Tester positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.