Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Well Digger position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

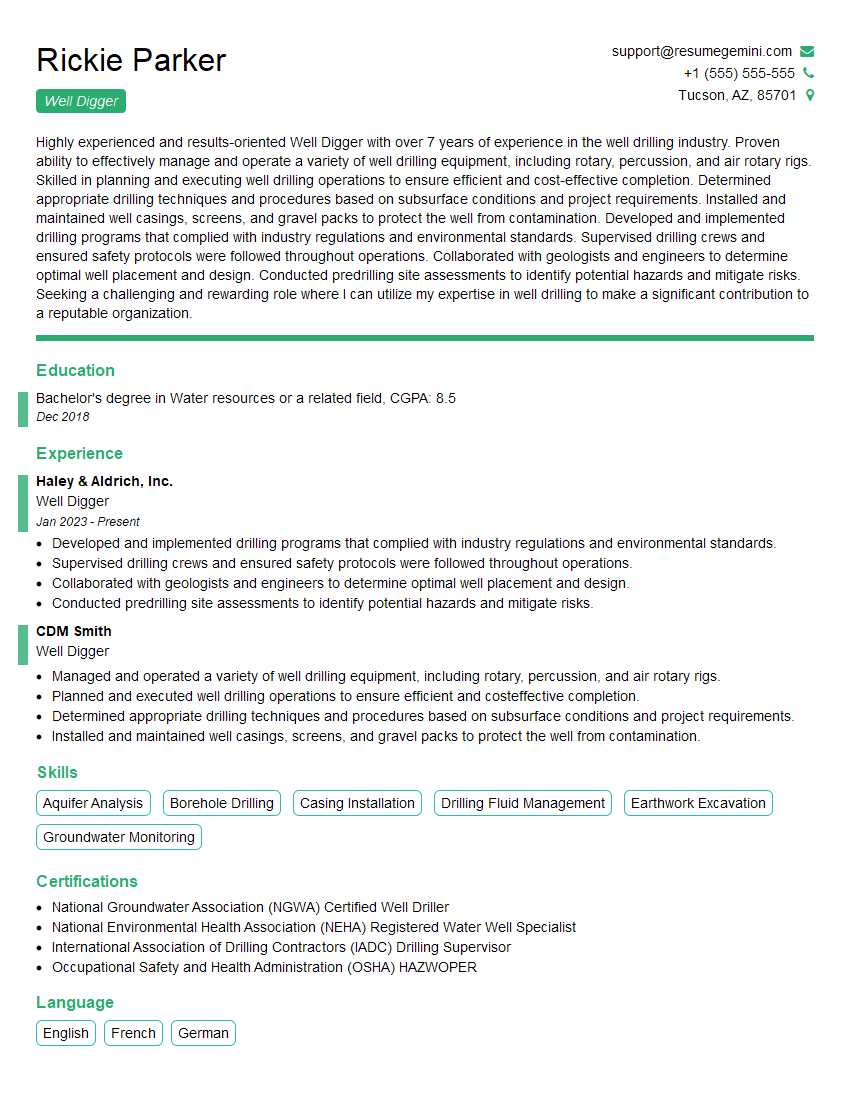

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Digger

1. What is the most important safety precaution to take when digging a well?

To ensure a safe working environment, it is crucial to prioritize safety when digging a well. The most vital safety precaution is to secure the well from potential cave-ins by casing it properly. This involves installing a sturdy casing pipe into the wellbore, which prevents the surrounding soil from collapsing and endangering workers or equipment.

2. What are the different types of drilling methods used in well digging?

Rotary drilling

- Uses a rotating bit to break down the rock or soil.

- Suitable for drilling through hard rock formations.

Percussion drilling

- Employs a heavy drill bit that repeatedly strikes the rock or soil to break it down.

- Effective for drilling through soft or medium-hard rock formations.

Down-the-hole drilling

- Involves using a down-the-hole hammer or bit that is directly attached to the drill string.

- Provides high drilling efficiency and is commonly used in hard rock formations.

3. How do you determine the depth at which to set the well casing?

The depth at which the well casing is set is determined based on several factors, including:

- The depth of the water-bearing zone that needs to be accessed.

- The geological conditions of the area, including the type and stability of the soil or rock formations.

- The diameter of the well casing being used.

- Local regulations and standards that may specify minimum casing depths.

4. What are the signs of a contaminated well?

There are several signs that may indicate well contamination:

- Changes in water color, odor, or taste.

- Presence of sediment or particles in the water.

- Unusual growth of algae or bacteria in the well.

- Health issues or illnesses in individuals who consume the water.

- High levels of contaminants detected through water testing.

5. How do you troubleshoot a well that is not producing enough water?

Troubleshooting a well with insufficient water production involves a systematic approach:

- Check the water level in the well to ensure it is not below the pump intake.

- Inspect the well casing and screen for any damage or obstructions.

- Examine the pump and its components for any malfunctions or wear and tear.

- Consider the possibility of a clogged or restricted aquifer, which may require further investigation or well development techniques.

6. What are the different types of well pumps available?

- Submersible pumps: Installed underwater and designed to withstand submersion.

- Jet pumps: Use water pressure to create a suction and draw water from the well.

- Centrifugal pumps: Utilize rotating impellers to move water.

- Hand pumps: Manually operated pumps that do not require electricity.

- Solar-powered pumps: Utilize solar panels to generate electricity and power the pump.

7. How do you calculate the horsepower of a well pump?

The horsepower of a well pump can be calculated using the following formula:

Horsepower = (Pump discharge in gallons per minute x Total dynamic head) / 3,960

- Pump discharge: The rate at which the pump delivers water in gallons per minute (GPM).

- Total dynamic head: The sum of the vertical lift, friction loss, and pressure losses in the system.

8. What are the common causes of well failure?

- Corrosion or damage to the well casing or screen.

- Pump malfunctions or breakdowns.

- Clogging or silting of the aquifer.

- Contamination of the well water.

- Changes in the geological conditions or water table levels.

9. How do you maintain and prolong the life of a well?

- Regular inspection and maintenance of the well and its components, including the pump, casing, and screen.

- Water testing to monitor water quality and detect any potential contamination.

- Well disinfection and cleaning to remove bacteria or sediment buildup.

- Proper well capping and sealing to prevent surface contaminants from entering the well.

10. What are the legal regulations and standards that apply to well digging and maintenance?

Well digging and maintenance are subject to various legal regulations and standards, which may vary depending on the jurisdiction. These regulations typically cover aspects such as:

- Well construction and design standards.

- Water quality testing and reporting requirements.

- Well abandonment and decommissioning procedures.

- Licensing and certification requirements for well diggers and contractors.

- Environmental protection and groundwater conservation regulations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Digger.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Digger‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Well Diggers are responsible for the construction and maintenance of various types of wells, ensuring the availability of water for residential, agricultural, and industrial purposes.

1. Well Construction

Plan, design, and implement well construction projects, based on geological conditions and client requirements.

- Determine optimal well depth, diameter, and casing materials.

- Select and operate drilling equipment, including rotary rigs, percussion rigs, and air hammers.

2. Well Maintenance

Monitor and maintain existing wells to ensure proper functioning and water quality.

- Inspect wells for damage, corrosion, or contamination.

- Clean and disinfect wells to remove sediment, bacteria, or other contaminants.

3. Well Development

Prepare new wells for use by removing excess drilling materials and developing water flow.

- Pump water from the well to remove sediment and fine particles.

- Surge or flush the well to enhance water yield and clarity.

4. Site Evaluation and Planning

Assess the feasibility and suitability of well construction sites.

- Conduct soil and groundwater testing to determine soil conditions, water availability, and potential hazards.

- Develop well plans and specifications, including construction materials, depth, and diameter.

Interview Tips

To ace an interview for a Well Digger position, it’s essential to prepare thoroughly and showcase your skills and experience. Here are some tips to help you stand out:

1. Research the Organization and Position

Familiarize yourself with the company’s mission, values, and recent projects to demonstrate your interest and alignment with their goals.

- Research industry best practices and technological advancements in well digging.

- Review relevant laws and regulations related to well construction and water safety.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience operating drilling equipment, your understanding of well construction techniques, and your ability to develop and maintain water sources.

- Quantify your accomplishments using specific metrics and results.

- Prepare examples of your ability to solve problems, work independently, and collaborate effectively.

3. Demonstrate Safety and Regulatory Knowledge

Well digging involves working in potentially hazardous environments. Highlight your commitment to safety and your knowledge of industry regulations related to well construction and water quality.

- Discuss your safety practices and use of personal protective equipment.

- Explain your understanding of well testing and water sampling procedures.

4. Be Prepared for Technical Questions

Interviewers may ask technical questions to assess your knowledge of equipment, well construction methods, and geological principles.

- Prepare to discuss different drilling techniques and their applications.

- Explain the role of casing and screen in well construction.

- Describe the principles of groundwater flow and aquifer characteristics.

5. Ask Informed Questions

Asking thoughtful questions at the end of the interview demonstrates your interest in the role and your proactive approach.

- Inquire about the company’s upcoming projects and growth plans.

- Ask about the opportunities for professional development and training.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Well Digger interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.