Feeling lost in a sea of interview questions? Landed that dream interview for Well Drill Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Well Drill Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

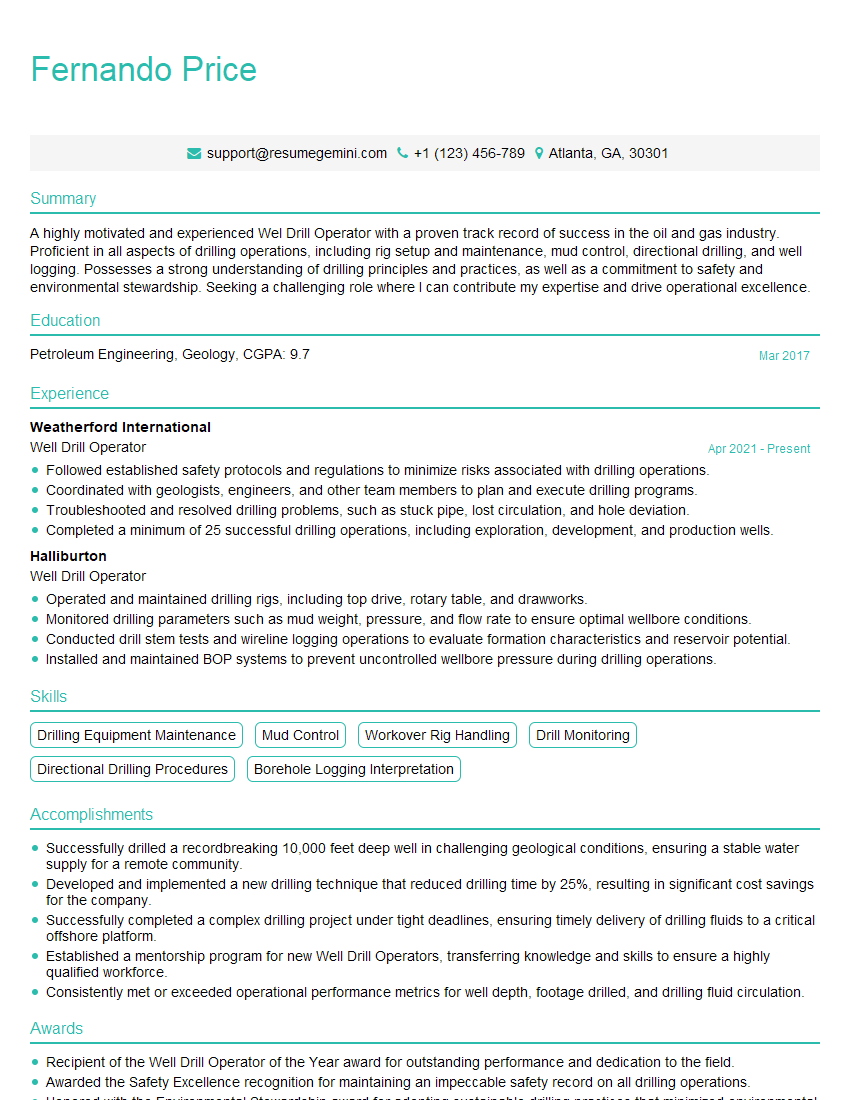

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Drill Operator

1. Explain how you plan and prepare for a well drilling project?

To plan and prepare for a well drilling project, I take the following steps:

- Review the project specifications and objectives.

- Gather and assess geological data to determine the target formation and drilling parameters.

- Develop a drilling program that outlines the well’s design, equipment requirements, and drilling schedule.

- Secure necessary permits and approvals from regulatory agencies.

- Mobilize equipment and materials to the drilling site and prepare the well pad.

2. How do you ensure safe and efficient operation of drilling equipment?

Pre-Operation Inspection

- Conduct thorough pre-operation inspections of all drilling equipment.

- Identify and mitigate potential hazards.

- Operate equipment within specified limits.

Drilling Optimization

- Monitor drilling parameters such as weight-on-bit, torque, and penetration rate.

- Adjust drilling parameters to optimize penetration rate and prevent equipment damage.

- Troubleshoot and resolve equipment issues promptly.

Emergency Preparedness

- Develop and implement emergency response plans.

- Train crew members on emergency procedures.

- Maintain emergency equipment in good working order.

3. How do you handle potential well control situations during drilling?

To handle potential well control situations during drilling, I follow these procedures:

- Monitor drilling parameters and identify any deviations that may indicate a well control issue.

- Implement appropriate well control techniques, such as closing the blow-out preventer (BOP) or injecting kill fluid.

- Collaborate with other crew members and supervisors to execute well control procedures effectively.

- Notify relevant authorities and stakeholders promptly in the event of a well control incident.

4. What are your responsibilities in managing and training a drilling crew?

My responsibilities in managing and training a drilling crew include:

- Providing clear instructions and guidance to crew members.

- Ensuring crew members are properly trained and certified.

- Establishing and maintaining a safe and efficient work environment.

- Monitoring crew performance and providing feedback.

- Coordinating with other departments and subcontractors.

5. How do you stay up-to-date with industry best practices and technological advancements in well drilling?

I stay up-to-date with industry best practices and technological advancements in well drilling through the following methods:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Participating in online forums and discussions.

- Seeking training and certification opportunities.

- Networking with other professionals in the field.

6. How do you ensure the accuracy and integrity of wellbore measurements and data?

To ensure the accuracy and integrity of wellbore measurements and data, I take the following steps:

- Calibrate and maintain measurement tools regularly.

- Follow established recording and data management protocols.

- Verify and cross-check data from multiple sources.

- Identify and mitigate potential sources of error.

- Document all measurements and data accurately.

7. What are the common geological formations encountered in well drilling and how do you adapt your drilling techniques accordingly?

Common geological formations encountered in well drilling include:

- Soft formations (e.g., clay, sand, silt): Use lower drilling weights and higher circulation rates.

- Hard formations (e.g., limestone, sandstone): Use higher drilling weights and lower circulation rates.

- Unconsolidated formations: Use casing to stabilize the wellbore.

- Fractured formations: Adjust drilling parameters to prevent lost circulation.

- High-pressure formations: Implement well control measures to prevent blowouts.

8. How do you prioritize safety in well drilling operations and what specific measures do you implement to mitigate risks?

Safety is my top priority in well drilling operations. I implement the following measures to mitigate risks:

- Conduct thorough risk assessments and develop risk mitigation plans.

- Train crew members on safety protocols and emergency procedures.

- Inspect equipment regularly and ensure it meets safety standards.

- Follow established safety protocols for handling hazardous materials and waste.

- Monitor weather conditions and adjust drilling operations accordingly.

9. What are the environmental regulations and best practices you follow in well drilling operations?

I ensure compliance with the following environmental regulations and best practices in well drilling operations:

- Minimize waste generation and dispose of waste properly.

- Protect surface water and groundwater from contamination.

- Preserve biodiversity and minimize impact on wildlife.

- Conduct environmental monitoring and reporting as required.

- Work with landowners and communities to address environmental concerns.

10. How do you resolve technical challenges and troubleshoot problems that may arise during drilling operations?

I troubleshoot problems that may arise during drilling operations by using the following steps:

- Identify the symptoms and potential causes of the problem.

- Consult technical documentation and consult with experts as needed.

- Develop and implement a solution to resolve the problem.

- Monitor the situation and make adjustments as necessary.

- Document the problem and solution for future reference.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Drill Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Drill Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Well Drill Operators are responsible for the safe and efficient operation of drilling rigs used to create boreholes for water wells, oil wells, and other purposes. Their primary tasks include:

1. Drilling Operations

Operating drilling rigs to bore holes into the ground using various drilling methods.

- Selecting and installing appropriate drilling bits and equipment for different soil conditions.

- Monitoring drilling parameters such as depth, pressure, and fluid flow to ensure optimal drilling performance.

2. Equipment Maintenance

Maintaining and servicing drilling rigs, including engines, pumps, and other equipment.

- Performing routine inspections and adjustments to ensure equipment is in good working order.

- Troubleshooting and repairing equipment malfunctions to minimize downtime.

3. Safety Compliance

Adhering to safety regulations and protocols to ensure a safe work environment.

- Wearing appropriate personal protective equipment (PPE) such as hard hats and safety glasses.

- Following established drilling procedures and using proper handling techniques to prevent accidents.

4. Site Management

Managing drilling sites, including preparing the site, setting up equipment, and ensuring proper disposal of drilling fluids and waste.

- Coordinating with other crew members, such as geologists and engineers, to ensure efficient operations.

- Maintaining accurate records of drilling activities, including depth, formation encountered, and any problems encountered.

Interview Tips

To ace an interview for a Well Drill Operator position, candidates should consider the following tips:

1. Research the Company and Position

Thoroughly research the company, its industry, and the specific requirements for the Well Drill Operator role. Understanding the company’s values, mission, and areas of expertise will demonstrate your interest and preparation.

- Visit the company’s website and social media profiles.

- Read industry publications and news articles to stay informed about current drilling trends and technologies.

2. Highlight Relevant Experience and Skills

Emphasize your relevant experience and skills that align with the job requirements. Quantify your accomplishments using specific examples and metrics whenever possible.

- Describe your experience operating drilling rigs, including the types of rigs and drilling methods you have used.

- Showcase your knowledge of drilling equipment, such as bits, pumps, and engines, and your ability to maintain and troubleshoot them.

3. Demonstrate Safety Awareness

Highlight your commitment to safety and your understanding of industry regulations and protocols. Emphasize your adherence to safety procedures and your ability to identify and mitigate potential risks.

- Describe your experience in following safety guidelines on drilling sites.

- Explain how you prioritize safety in your daily work and decision-making processes.

4. Prepare for Technical Questions

Expect to be asked technical questions about drilling operations, equipment maintenance, and safety procedures. Review common drilling techniques, equipment specifications, and industry standards to prepare for these questions.

- Practice answering questions about different drilling methods, such as rotary drilling, percussion drilling, and jet drilling.

- Be familiar with the various types of drilling bits and their applications.

5. Show Enthusiasm and Coachability

Convey your enthusiasm for the Well Drill Operator role and your eagerness to learn and contribute to the team. Emphasize your willingness to take on challenges and your ability to adapt to changing conditions.

- Explain why you are interested in the drilling industry and what motivates you in this field.

- Express your desire to continue developing your skills and knowledge.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Well Drill Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!