Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Well Service Derrick Worker position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

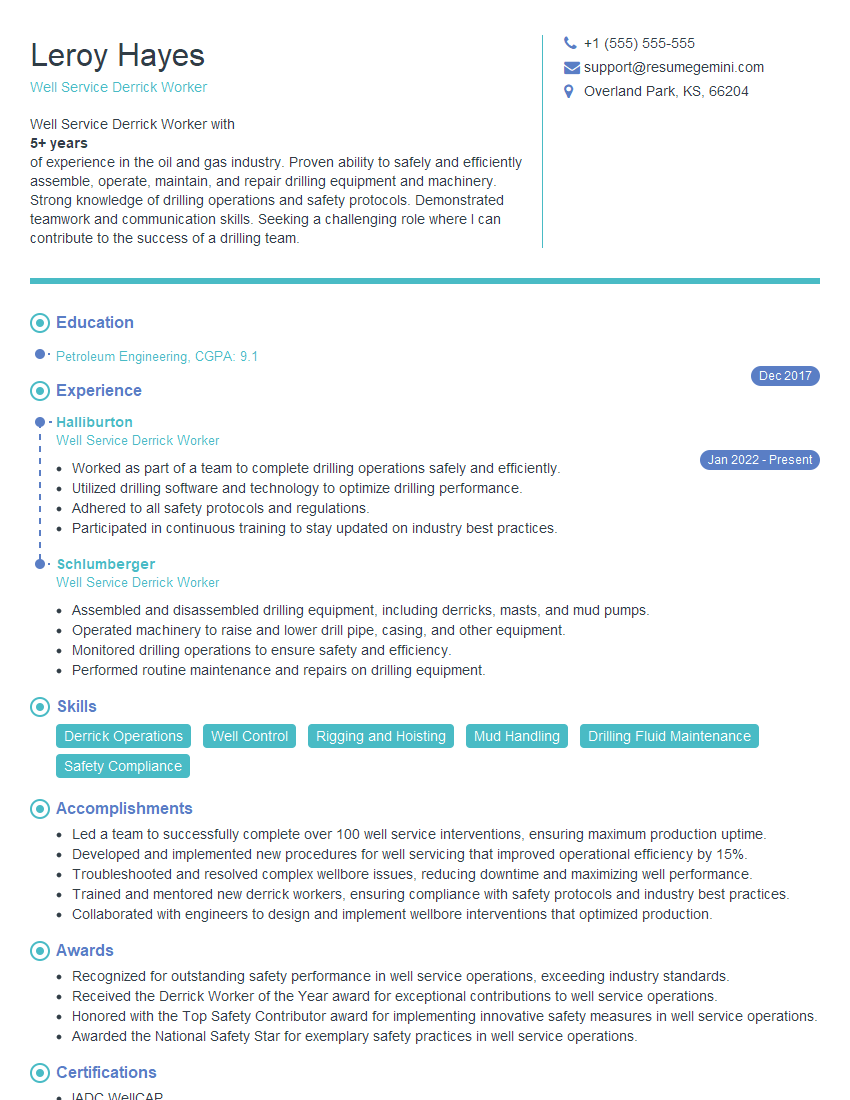

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Service Derrick Worker

1. What are the main components of a well service rig?

The main components of a well service rig include:

- The derrick, which is a tall, triangular structure that supports the drilling equipment.

- The drawworks, which is a powerful winch that lifts and lowers the drilling tools.

- The rotary table, which rotates the drill pipe.

- The mud pumps, which circulate drilling fluid through the drill pipe and up the wellbore.

- The blowout preventer, which is a safety device that prevents uncontrolled flow of well fluids.

2. What are the different types of well service operations?

Drilling

- Drilling a new well

- Deepening an existing well

- Sidetracking a well

Completion

- Installing casing and cement

- Perforating the casing

- Installing production tubing

Workover

- Repairing or replacing damaged equipment

- Stimulating production

- Abandoning a well

3. What are the safety hazards associated with well service operations?

- Falls from height

- Struck by or caught between objects

- Exposure to hazardous chemicals

- Fires and explosions

- Blowouts

4. What are the steps involved in preparing a well for a well service operation?

- Shut-in the well and bleed off pressure.

- Rig up the well service equipment.

- Circulate drilling fluid through the wellbore to clean it out.

- Set the blowout preventer.

- Test the blowout preventer.

5. What are the different types of drilling fluids?

- Water-based drilling fluids

- Oil-based drilling fluids

- Synthetic-based drilling fluids

6. What are the properties of a good drilling fluid?

- It should be able to cool and lubricate the drill bit.

- It should be able to remove cuttings from the wellbore.

- It should be able to control formation pressure.

- It should be able to prevent lost circulation.

7. What are the different types of drill bits?

- Drag bits

- Roller cone bits

- PDC bits

8. What are the factors that affect the drilling rate?

- The type of drilling fluid

- The type of drill bit

- The weight on bit

- The rotary speed

- The formation hardness

9. What are the signs of a lost circulation zone?

- A sudden drop in drilling fluid level

- A decrease in drilling rate

- An increase in pump pressure

- The presence of lost circulation material in the returns

10. What are the different methods of controlling lost circulation?

- Using lost circulation material

- Using a cement plug

- Using a drilling fluid with a high solids content

- Using a drilling fluid with a low viscosity

- Reducing the weight on bit

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Service Derrick Worker.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Service Derrick Worker‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Well Service Derrick Worker is responsible for a variety of tasks related to the operation and maintenance of oil and gas wells. Key responsibilities include:

1. Rigging Up and Down

Assembling and disassembling the drilling rig and its components, including the derrick, drawworks, and mud pumps.

- Inspecting and maintaining all rigging equipment to ensure safety and efficiency.

- Following proper procedures and safety guidelines during rigging operations.

2. Handling Pipe and Tubing

Running and pulling drill pipe, casing, and tubing from the wellbore.

- Using proper techniques to connect and disconnect pipe and tubing.

- Monitoring the condition of pipe and tubing and identifying any potential issues.

3. Mixing and Pumping Fluids

Preparing and circulating drilling fluids to maintain wellbore stability and control formation pressure.

- Understanding the properties and functions of different drilling fluids.

- Following proper procedures for mixing and pumping fluids.

4. Monitoring Well Parameters

Observing and recording key well parameters, such as drilling depth, formation pressure, and fluid levels.

- Using gauges and instruments to monitor well conditions.

- Identifying and responding to any deviations from normal operating parameters.

5. Troubleshooting and Maintenance

Identifying and resolving equipment malfunctions and operational issues.

- Performing basic troubleshooting and maintenance tasks.

- Reporting any major issues to the supervisor for further action.

Interview Tips

To prepare for an interview for a Well Service Derrick Worker position, candidates should consider the following tips:

1. Research the Company and Position

Learn about the company’s operations, industry reputation, and the specific requirements of the Derrick Worker role.

- Visit the company website and read industry news articles.

- Identify the key skills and experience required for the job.

2. Practice Answering Common Interview Questions

Prepare answers to common interview questions related to your experience, qualifications, and motivation for the role.

- Use the STAR method (Situation, Task, Action, Result) to structure your responses.

- Quantify your accomplishments whenever possible.

3. Highlight Your Relevant Experience and Skills

Emphasize your experience in oil and gas operations, particularly in areas related to well servicing.

- Showcase your ability to operate and maintain drilling equipment.

- Highlight your knowledge of drilling fluids and well monitoring techniques.

4. Demonstrate Your Safety-Consciousness

Stress the importance of safety in your work and your commitment to following industry best practices.

- Explain your understanding of well servicing hazards and risk management.

- Provide examples of how you have maintained a safe work environment.

5. Ask Informed Questions

Prepare thoughtful questions to ask your interviewers, demonstrating your interest and engagement.

- Ask about the company’s safety culture and training programs.

- Inquire about career advancement opportunities and professional development.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Well Service Derrick Worker interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.