Feeling lost in a sea of interview questions? Landed that dream interview for Well Site Drilling Engineer but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Well Site Drilling Engineer interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

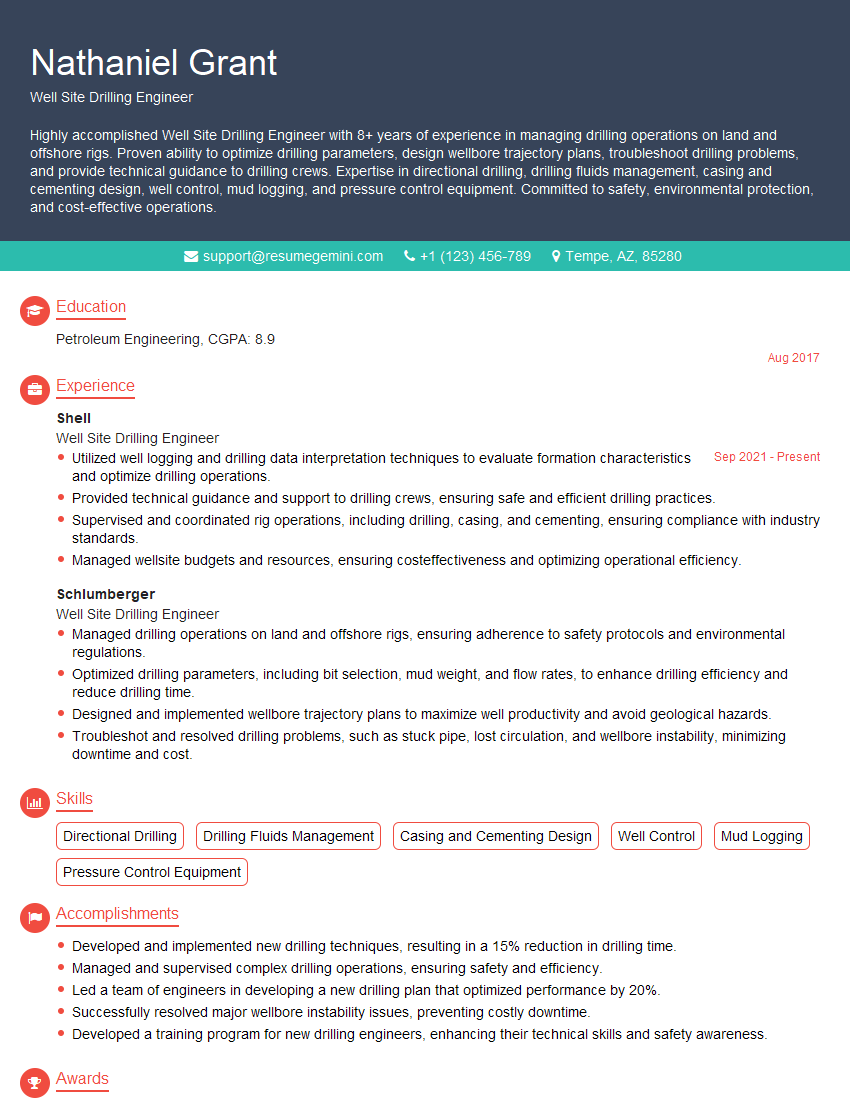

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Site Drilling Engineer

1. Describe the key responsibilities of a Well Site Drilling Engineer?

- Plan and execute well construction operations, including drilling, casing, and completion.

- Monitor drilling operations and make real-time decisions to optimize performance and safety.

- Communicate with rig contractors, service companies, and other stakeholders to ensure seamless execution.

- Analyze well data, such as drilling parameters, formation pressure, and fluid properties, to optimize drilling strategies.

- Troubleshoot drilling issues and implement solutions to prevent non-productive time.

2. Explain the different drilling methods used in oil and gas industry?

- Rotary Drilling: Uses a rotating bit to bore through the earth.

- Directional Drilling: Used to deviate the wellbore from a vertical path to reach specific targets.

- Horizontal Drilling: Creates horizontal sections of the wellbore to maximize reservoir exposure.

- Underbalanced Drilling: Maintains a lower pressure in the wellbore than in the formation to enhance recovery.

- Air Drilling: Uses air or gas instead of drilling mud as the circulating fluid.

3. How do you determine the appropriate drilling fluid for a specific geological formation?

- Formation characteristics: Permeability, porosity, reactivity, and overpressure.

- Drilling objectives: Hole cleaning, wellbore stability, and formation protection.

- Drilling conditions: Temperature, pressure, and fluid properties.

- Environmental considerations: Biodegradability, toxicity, and disposal regulations.

- Compatibility with other fluids and chemicals used in drilling operations.

4. Describe the role of drilling parameters in optimizing drilling performance?

- Weight on bit (WOB): Force applied to the bit.

- Rotary speed (RPM): Speed at which the bit rotates.

- Mud flow rate: Rate at which drilling fluid is pumped.

- Bit type: Type of bit used for specific formation characteristics.

- Drilling fluid properties: Density, viscosity, and filtration properties.

- Formation pressure: Pressure in the geological formation being drilled.

5. Explain the importance of well control during drilling operations?

- Prevent uncontrolled flow of formation fluids (oil, gas, or water) into the wellbore.

- Protect drilling crew, equipment, and the environment.

- Maintain wellbore stability and prevent blowouts.

- Ensure smooth transition to production or abandonment.

- Comply with industry regulations and safety standards.

6. Describe the different types of well logging tools used in drilling operations?

- Wireline logging: Tools lowered into the wellbore on a wire cable.

- Slickline logging: Tools run into the wellbore on a slickline (a flexible steel cable).

- Coiled tubing logging: Tools deployed using coiled tubing (a continuous steel pipe).

- Logging while drilling (LWD): Tools integrated into the drill string to acquire real-time data.

- Measurement while drilling (MWD): Tools incorporated into the drill string to provide directional and other drilling data.

7. Explain the principles of directional drilling and its applications?

Principles: Use of special tools (e.g., steering tools, rotary steerable systems) to control the direction of the wellbore.

Applications:

- Accessing targets not directly below the rig.

- Enhancing reservoir recovery by accessing multiple sections.

- Avoiding obstacles in the subsurface.

- Drilling under environmentally sensitive areas.

8. Describe the role of a Well Site Drilling Engineer in managing drilling risks?

- Identify potential risks during drilling operations.

- Develop and implement risk mitigation strategies.

- Monitor drilling parameters and make real-time decisions to avoid or minimize risks.

- Train rig crews on risk management practices.

- Report and document risk management efforts.

9. Explain the importance of drilling waste management in oil and gas operations?

- Prevent environmental pollution by treating and disposing of drilling waste responsibly.

- Reduce environmental liability and protect sensitive ecosystems.

- Comply with industry regulations and environmental standards.

- Maximize resource recovery by recycling and reusing drilling waste.

- Promote sustainable drilling practices and reduce the industry’s carbon footprint.

10. Describe the key challenges and emerging trends in Well Site Drilling Engineering?

- Drilling in extreme environments: Deepwater, ultra-deepwater, and arctic drilling.

- Managing environmental regulations: Reducing emissions, minimizing waste, and protecting biodiversity.

- Digitalization and automation: Data analytics, AI, and remote operations.

- Sustainable drilling practices: Minimizing water consumption, reducing carbon footprint, and promoting resource efficiency.

- Collaboration and innovation: Working with contractors, service providers, and academia to develop new technologies and solutions.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Site Drilling Engineer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Site Drilling Engineer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Well Site Drilling Engineers play a pivotal role in the safe and efficient execution of oil and gas drilling operations. Their primary responsibilities encompass:

1. Plan and Oversee Drilling Activities

Develop drilling programs, determine drilling parameters, and monitor progress to ensure adherence to design specifications and safety protocols.

2. Supervise and Coordinate Drilling Team

Provide technical leadership to drilling personnel, ensuring proper execution of operations, and coordinating with other departments such as geology and production.

3. Monitor Drilling Equipment and Performance

Monitor drilling equipment performance, conduct inspections, and perform maintenance to maintain optimal functionality and prevent equipment failures.

4. Ensure Compliance with Regulations

Ensure compliance with industry standards, environmental regulations, and company policies, implementing measures to minimize risks and protect the environment.

5. Analyze Drilling Data and Implement Improvements

Analyze drilling data, identify potential issues, and implement corrective actions or process improvements to enhance efficiency and safety.

6. Prepare Engineering Reports and Documentation

Document drilling operations, prepare technical reports, and present findings to stakeholders, including supervisors, engineers, and clients.

Interview Tips

To ace an interview for a Well Site Drilling Engineer position, consider the following tips:

1. Research the Company and Industry

Demonstrate your knowledge of the company’s operations, industry trends, and recent drilling projects. This shows your interest and commitment to the field.

2. Highlight Your Technical Expertise

Emphasize your understanding of drilling principles, equipment, and drilling fluids. Provide examples of your experience in developing and executing drilling programs.

3. Showcase Your Leadership Abilities

Describe your experience in managing drilling teams effectively, motivating individuals, and resolving conflicts. Highlight your communication and interpersonal skills.

4. Discuss Safety and Environmental Awareness

Demonstrate your commitment to safety and environmental protection by explaining your knowledge of industry regulations and best practices. Share examples of how you have implemented these measures in your previous roles.

5. Prepare for Common Interview Questions

Practice answering typical interview questions, such as “Why are you interested in this role?” “What are your strengths and weaknesses?” and “Why should we hire you?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Well Site Drilling Engineer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!