Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Well Testing Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Well Testing Operator so you can tailor your answers to impress potential employers.

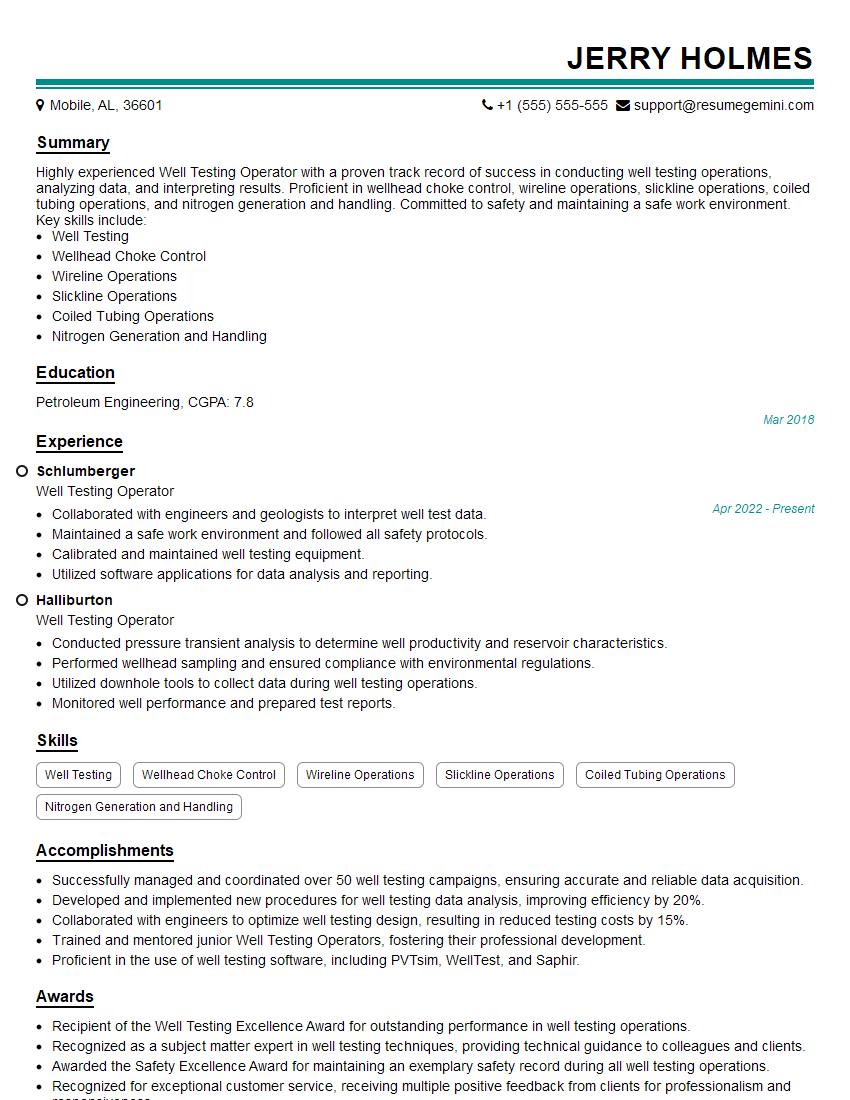

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Well Testing Operator

1. Explain the purpose and function of a well testing separator?

A well testing separator is a device used to separate the produced fluids (oil, gas, and water) from a well during well testing operations. Its primary functions include:

- Separate the produced fluids based on their different densities.

- Measure the flow rates and volumes of the separated fluids.

- Control the pressure and temperature of the fluids to ensure safe and efficient operation.

2. Describe the different types of well testing separators?

Horizontal Separators

- Designed to handle large volumes of fluids.

- Utilize gravity to separate fluids based on density.

Vertical Separators

- Compact and efficient for smaller volumes of fluids.

- Use centrifugal force to separate fluids.

Three-Phase Separators

- Designed to separate oil, gas, and water.

- Often equipped with coalescers to enhance oil-water separation.

3. What are the key factors to consider when selecting a well testing separator?

When selecting a well testing separator, several key factors must be considered:

- Production rates and fluid properties (oil, gas, and water).

- Separator efficiency and capacity.

- Pressure and temperature requirements.

- Available space and installation constraints.

- Safety features and regulatory compliance.

4. How do you conduct a well test using a well testing separator?

Conducting a well test using a well testing separator involves the following steps:

- Install the separator and connect it to the wellhead.

- Calibrate the separator and verify its performance.

- Start production and allow fluids to flow through the separator.

- Monitor and record fluid flow rates, pressures, and temperatures.

- Collect and analyze fluid samples to determine fluid properties (e.g., API gravity, gas-oil ratio).

- Interpret the well test data to evaluate well performance and reservoir characteristics.

5. What are the potential hazards associated with well testing operations using a separator?

Well testing operations using a separator pose potential hazards such as:

- High pressure and temperature fluids.

- Toxic and flammable gases.

- Electrical hazards.

- Mechanical failures.

- Environmental risks (e.g., oil spills, gas leaks).

6. How do you ensure the safety of personnel and equipment during well testing operations?

Ensuring safety during well testing operations involves:

- Following established safety protocols and procedures.

- Wearing appropriate personal protective equipment (PPE).

- Using properly calibrated and maintained equipment.

- Regularly inspecting equipment and facilities.

- Implementing emergency response plans.

- Training personnel on safety hazards and procedures.

7. What are the latest advancements in well testing separator technology?

Recent advancements in well testing separator technology include:

- High-efficiency separators with improved fluid separation capabilities.

- Compact and portable separators for field operations.

- Automated separators with real-time data monitoring and control.

- Environmentally friendly separators that minimize emissions and waste.

8. How do you stay updated with the latest trends and developments in well testing separator technology?

To stay updated with the latest trends and developments in well testing separator technology, I:

- Attend industry conferences and exhibitions.

- Read technical papers and journals.

- Network with professionals in the field.

- Participate in training programs and workshops.

9. What are the major challenges you have faced as a Well Testing Operator, and how did you overcome them?

A major challenge I faced was managing a well test with high gas-oil ratios. To overcome this, I worked closely with the engineering team to design a separator configuration that could effectively handle the high gas volumes. I also implemented a specialized gas handling system to prevent gas blowouts and ensure safe operation.

10. Why are you interested in this Well Testing Operator position with our company?

I am eager to join your company as a Well Testing Operator because I am impressed by your commitment to technological innovation and safety. I believe that my skills and experience in well testing operations, particularly in the area of separator optimization, would be valuable to your team. I am confident that I can contribute to the success of your well testing projects while ensuring adherence to the highest safety standards.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Well Testing Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Well Testing Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Well Testing Operators play a vital role in the oil and gas industry, ensuring safe and efficient well testing operations. Their key responsibilities include:

1. Well Testing Procedures

Execute well testing procedures as per established standards and company protocols.

- Operate testing equipment, such as pressure recorders, gauges, and flow meters.

- Collect and analyze well test data to evaluate reservoir characteristics and well performance.

2. Equipment Maintenance and Calibration

Maintain and calibrate well testing equipment to ensure accuracy and reliability.

- Perform routine maintenance on equipment, including cleaning, lubrication, and troubleshooting.

- Calibrate equipment regularly using certified standards.

3. Safety and Compliance

Follow established safety protocols and industry regulations to ensure a safe work environment.

- Wear appropriate personal protective equipment (PPE).

- Identify and mitigate potential hazards during well testing operations.

4. Reporting and Documentation

Prepare and maintain accurate records of well testing operations.

- Complete well testing reports, including test results, observations, and recommendations.

- Maintain equipment maintenance records and calibration certificates.

Interview Tips

To ace the interview for a Well Testing Operator position, it is crucial to prepare thoroughly. Here are some tips to help you excel:

1. Research the Company and Industry

Familiarize yourself with the company’s operations, values, and recent news. Understand the industry’s current trends and challenges.

- Visit the company website and social media pages.

- Read industry publications and attend relevant conferences.

2. Highlight Your Skills and Experience

Emphasize your technical skills, including equipment operation, data analysis, and safety procedures. Quantify your experience with specific examples.

- Showcase your ability to interpret well test data and provide meaningful insights.

- Describe your experience in maintaining and calibrating well testing equipment.

3. Prepare for Common Interview Questions

Research common interview questions and practice your answers. Focus on demonstrating your knowledge, skills, and enthusiasm for the role.

- Example Question: Tell us about a time you handled a challenging well testing situation.

- Example Answer: “In one instance, I encountered an equipment malfunction during a well test. I swiftly identified the issue, repaired the equipment, and resumed testing without compromising safety.”

4. Demonstrate Your Safety Mindset

Emphasize your commitment to safety and compliance in all aspects of well testing operations.

- Explain your understanding of industry safety regulations and best practices.

- Share examples of how you have implemented safety measures in previous roles.

Next Step:

Now that you’re armed with the knowledge of Well Testing Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Well Testing Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini