Feeling lost in a sea of interview questions? Landed that dream interview for Wet and Dry Sugar Bin Operator but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wet and Dry Sugar Bin Operator interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

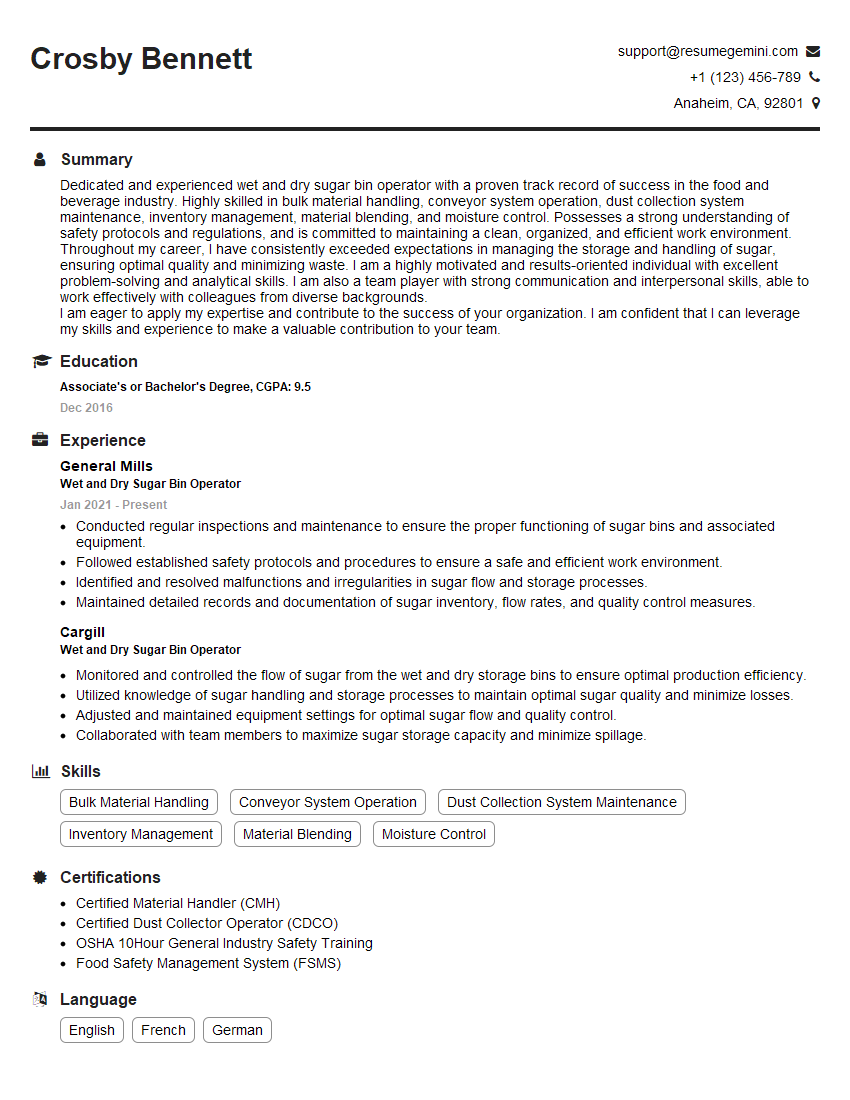

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet and Dry Sugar Bin Operator

1. Can you explain your understanding of the role and responsibilities of a Wet and Dry Sugar Bin Operator?

As a Wet and Dry Sugar Bin Operator, I am responsible for operating and maintaining the equipment used to handle and store wet and dry sugar, ensuring the smooth flow of materials within the facility.

- Operating and monitoring the sugar bins, including loading, unloading, and maintaining optimal sugar levels.

- Controlling the flow of sugar using conveyors, valves, and other equipment.

2. Can you describe the hazards associated with working as a Wet and Dry Sugar Bin Operator and the safety precautions you would take?

The role involves working with heavy machinery and hazardous materials like sugar dust, so safety is paramount. I am familiar with the potential hazards, including:

Potential Hazards

- Exposure to sugar dust

- Operating heavy machinery

- Working in confined spaces

I prioritize safety by adhering to established protocols, wearing appropriate personal protective equipment (PPE), and maintaining a clean and organized work area.

Safety Precautions

- Wear a respirator to prevent inhalation of sugar dust.

- Follow lockout/tagout procedures when working on machinery.

- Ensure adequate ventilation in confined spaces.

3. How do you ensure the quality of sugar during storage and handling?

Maintaining sugar quality is vital. I follow strict procedures to prevent contamination and preserve its integrity:

- Regularly inspecting sugar bins and conveyors for cleanliness and signs of damage.

- Controlling temperature and humidity levels within storage areas to prevent sugar caking and spoilage.

- Adhering to FIFO (First In, First Out) principles to ensure older sugar is used first.

4. Can you explain the role of batch tracking in sugar bin operations?

Batch tracking is crucial for maintaining sugar quality and traceability. I ensure accurate batch tracking by:

- Labeling each batch of sugar with a unique identifier.

- Maintaining records of sugar origin, storage conditions, and usage.

- Verifying batch numbers during loading and unloading to prevent mix-ups.

5. How do you handle equipment malfunctions or emergencies as a Wet and Dry Sugar Bin Operator?

Equipment malfunctions and emergencies require prompt attention to minimize downtime and ensure safety. My approach includes:

- Identifying the issue and assessing its severity.

- Following established protocols for troubleshooting and repairs.

- If necessary, contacting maintenance personnel for assistance.

- Documenting the incident and any corrective actions taken.

6. Can you describe the importance of preventative maintenance in sugar bin operations?

Preventative maintenance is essential for maximizing equipment uptime and minimizing costly repairs. As a Wet and Dry Sugar Bin Operator, I perform regular maintenance tasks, such as:

- Inspecting and cleaning equipment according to established schedules.

- Lubricating moving parts to reduce wear and tear.

- Monitoring equipment performance and identifying potential issues early on.

7. How do you prioritize tasks and manage your time effectively as a Wet and Dry Sugar Bin Operator?

Effective time management is crucial in this role. I prioritize tasks based on urgency and importance, ensuring that critical operations are handled promptly. I use a combination of techniques to manage my time:

- Creating daily task lists and prioritizing urgent items.

- Breaking down large tasks into smaller, manageable chunks.

- Delegating responsibilities to other team members when appropriate.

8. Can you explain the role of automation in modern sugar bin operations?

Automation plays a significant role in streamlining sugar bin operations. I am familiar with various automated systems, such as:

- Automated loading and unloading systems.

- Level sensors and control systems to maintain optimal sugar levels.

- Data logging and reporting systems to monitor and analyze operations.

9. How do you stay updated with the latest industry best practices and technology advancements in sugar bin operations?

Continuous learning is crucial in this field. I stay updated with industry best practices and technology advancements through:

- Attending industry conferences and workshops.

- Reading technical journals and publications.

- Networking with other professionals in the field.

10. What are your career goals and how do you see this role contributing to them?

My career goal is to advance in the field of sugar bin operations and eventually become a shift supervisor or plant manager. I believe this role is an excellent opportunity for me to develop my skills and gain valuable experience that will contribute to my long-term career aspirations.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet and Dry Sugar Bin Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet and Dry Sugar Bin Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wet and Dry Sugar Bin Operator is responsible for monitoring and controlling the blending and storage of raw sugar in assigned bins, ensuring final sugar product meets customer specifications. This multifaceted role demands proficiency in operating specialized equipment, maintaining optimal process conditions, and troubleshooting potential issues that may arise in the production process.

1. Monitor and Operate Blending and Storage Systems

The operator closely monitors the sugar blending and storage processes, ensuring that all blending and storage systems operate smoothly and efficiently. They consistently track sugar levels, monitor bin temperatures, and verify that all safety protocols are strictly adhered to.

2. Maintain Optimal Process Conditions

Maintaining optimal process conditions is paramount to the role, as the operator must ensure that blend ratios, moisture levels, and temperature conditions are precise to meet sugar quality specifications and prevent degradation. Regular inspections and meticulous data logging are crucial in maintaining these optimal conditions.

3. Inspect and Maintain Equipment

The Wet and Dry Sugar Bin Operator is responsible for regularly inspecting and maintaining plant machinery, ensuring its smooth and safe operation. They diligently monitor equipment conditions, identify potential issues, and proactively address maintenance needs to prevent breakdowns or disruptions in the sugar production process.

4. Troubleshooting and Problem-solving

In the event of operational issues or unexpected challenges, the operator must swiftly assess and troubleshoot the underlying cause. They methodically isolate the problem, promptly implement corrective actions, and effectively resolve any deviations that may arise, ensuring that production schedules are maintained.

Interview Tips

To ace the interview for a Wet and Dry Sugar Bin Operator role, meticulous preparation is essential. Thoroughly familiarize yourself with the key responsibilities outlined above and delve into the following tips to elevate your performance.

1. Research the Company and Industry

Demonstrate your keen interest in the company and sugar industry by researching its history, products, and current market trends. This knowledge will not only impress the interviewers but also enable you to engage in meaningful discussions about your potential contributions to the team.

2. Highlight Relevant Experience and Skills

Emphasize your prior experience in operating sugar blending and storage systems. Showcase your proficiency in maintaining optimal process conditions, troubleshooting equipment issues, and adhering to safety regulations. Quantify your accomplishments whenever possible to provide concrete evidence of your capabilities.

3. Prepare for Technical Questions

Anticipate technical questions related to sugar blending and storage processes. Study the principles of sugar handling, moisture control, and temperature management. Be prepared to discuss your understanding of equipment operation and maintenance procedures, demonstrating your technical competence.

4. Practice Common Interview Questions

Rehearse common interview questions, such as “Why are you interested in this role?” or “Describe your strengths and weaknesses.” Craft thoughtful and succinct answers that align with the job requirements and highlight your qualifications. Practice delivering your responses confidently and professionally.

5. Showcase Your Problem-Solving Abilities

Interviewers often pose hypothetical scenarios to assess your problem-solving abilities. Prepare examples from your previous experiences where you successfully identified and resolved operational issues in a sugar processing plant. Explain your thought process and the steps you took to resolve the challenges.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wet and Dry Sugar Bin Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wet and Dry Sugar Bin Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.