Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wet-End Operator interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wet-End Operator so you can tailor your answers to impress potential employers.

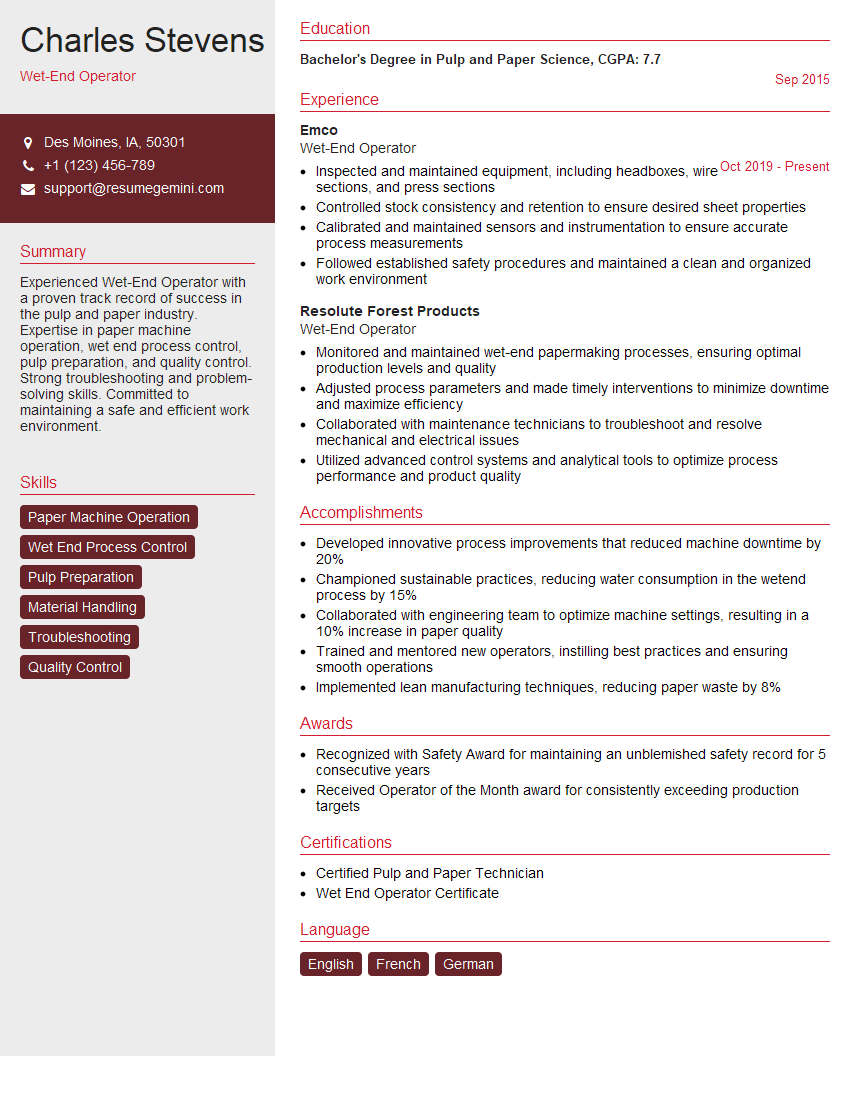

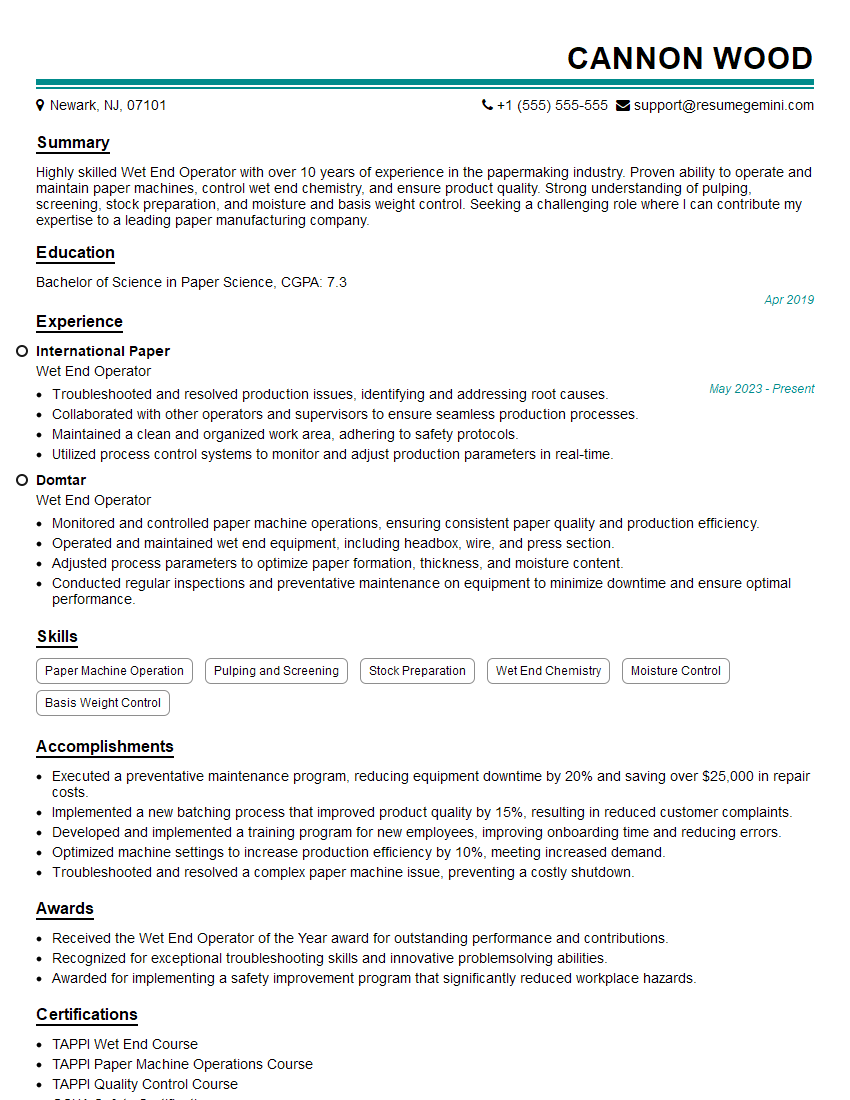

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet-End Operator

1. Explain the process involved in preparing pulp for paper production?

The process of preparing pulp for paper production involves several key steps:

- Pulping: The raw material (wood chips, recycled paper, etc.) is mechanically or chemically processed to separate the cellulose fibers from other components.

- Screening: The pulp is passed through screens to remove impurities such as bark, knots, and plastic contaminants.

- Washing: The pulp is washed with water to remove excess chemicals and other undesirable substances.

- Bleaching: The pulp may be bleached using chemicals (e.g., chlorine, oxygen, hydrogen peroxide) to improve its brightness and remove impurities.

- Refining: The pulp is passed through refiners to adjust its fiber properties (length, thickness, strength) and improve its papermaking qualities.

2. What are the key parameters that influence the quality of the wet end of a paper machine?

Paper stock properties

- Fiber length distribution

- Pulp consistency

- Pulp pH

- Additive concentration

Machine operation

- Headbox design

- Flow rate

- Wire speed

- Vacuum pressure

3. Describe the role of a wet-end operator in a paper mill?

The wet-end operator is responsible for:

- Monitoring and controlling the wet end of the paper machine, including the headbox, wire section, and press section.

- Maintaining stable pulp flow and consistency.

- Adjusting machine parameters to optimize paper quality.

- Troubleshooting and resolving issues related to wet-end operations.

- Performing routine maintenance and cleaning of equipment.

4. What are some common problems encountered during wet-end operation and how do you address them?

Common problems encountered during wet-end operation include:

- Streaking: Caused by uneven distribution of fibers in the paper sheet. Can be addressed by adjusting the headbox flow and consistency.

- Holes and tears: Caused by weak or damaged fibers. Can be addressed by optimizing the pulp refining process and reducing machine speed.

- Edge breaks: Caused by insufficient drainage on the wire section. Can be addressed by increasing vacuum pressure and adjusting the wire tension.

- Linting: Caused by loose fibers on the paper surface. Can be addressed by optimizing the refining process and using surface sizing agents.

5. How do you ensure the quality of the paper produced at the wet end?

I ensure the quality of the paper produced at the wet end by:

- Closely monitoring all process parameters, including pulp consistency, flow rate, and wire speed.

- Conducting regular tests on the paper sheet, such as tensile strength, tear resistance, and brightness.

- Making necessary adjustments to the machine operation based on the test results.

- Working closely with other departments, such as the pulp mill and the finishing department, to optimize the entire papermaking process.

6. What are the safety precautions that you take while working in the wet end of a paper mill?

I prioritize safety while working in the wet end of a paper mill by:

- Wearing appropriate personal protective equipment (PPE), including gloves, safety glasses, and earplugs.

- Following all safety protocols and procedures.

- Being aware of potential hazards, such as slippery floors and moving machinery.

- Reporting any unsafe conditions or practices to my supervisor immediately.

- Receiving regular safety training and refresher courses.

7. How do you stay updated on the latest developments and best practices in wet-end operation?

I stay updated on the latest developments and best practices in wet-end operation by:

- Reading industry publications and attending conferences.

- Participating in training programs and workshops.

- Networking with other wet-end operators and professionals.

- Seeking advice from my supervisor and other experienced operators.

- Continuously researching and exploring new technologies and techniques.

8. Describe a situation where you successfully identified and resolved a problem at the wet end of the paper machine.

In one instance, I noticed a sudden increase in the number of edge breaks on the paper sheet. I immediately checked the wire tension and vacuum pressure, but they were within normal limits. I then investigated the pulp consistency and found that it had dropped below the recommended level. I adjusted the pulp flow and consistency, and the edge breaks were eliminated.

9. How do you handle multiple tasks and prioritize your responsibilities during a busy shift?

During a busy shift, I handle multiple tasks and prioritize my responsibilities by:

- Creating a clear to-do list and prioritizing the tasks based on urgency and importance.

- Using effective time management techniques to allocate my time wisely.

- Delegating tasks to other team members when appropriate.

- Requesting assistance from my supervisor or colleagues when needed.

- Staying focused and avoiding distractions.

10. What motivates you to excel in your role as a wet-end operator?

I am motivated to excel in my role as a wet-end operator because:

- I am passionate about the papermaking process and the role that I play in producing high-quality paper.

- I enjoy the challenge of solving problems and optimizing the wet-end operation.

- I take pride in my work and strive to consistently meet or exceed expectations.

- I believe that my contributions make a positive impact on the company and the industry.

- I am eager to learn and grow in my role and to contribute to the success of the team.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet-End Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet-End Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wet-End Operator is responsible for the operation of the wet-end of a paper machine, which is the section of the machine where the paper web is formed. Key job responsibilities include:1. Preparing the paper machine

This involves ensuring that all equipment is in good working order, that the correct raw materials are loaded, and that the machine is set up to produce the desired type of paper.

2. Operating the paper machine

This involves monitoring the machine’s operation, making adjustments as necessary, and responding to any problems that may occur.

3. Testing the paper

This involves taking samples of the paper web and testing it to ensure that it meets the desired specifications.

4. Maintaining the paper machine

This involves cleaning and lubricating the machine, as well as replacing any worn or damaged parts.

5. Troubleshooting and solving problems

This involves identifying and correcting any problems that may occur with the paper machine.

Interview Tips

To help candidates ace their interview for a Wet-End Operator position, here are some tips and hacks:1. Research the company and the position

This will help you to understand the company’s culture and the specific requirements of the position, which will allow you to tailor your answers accordingly.

2. Practice your answers to common interview questions

There are a number of common interview questions that you can expect to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Make sure you have a prepared answer for each one, and practice delivering it in a clear and concise manner.

3. Prepare questions to ask the interviewer

Asking the interviewer questions at the end of the interview is a great way to show that you are interested in the position and that you have done your research. It also gives you an opportunity to learn more about the company and the position.

4. Dress professionally and arrive on time for the interview

First impressions matter, so make sure you dress professionally and arrive on time for your interview. This will show the interviewer that you are serious about the position and that you respect their time.

5. Be confident and enthusiastic

Interviewers are looking for candidates who are confident and enthusiastic about the position. Be yourself, and let the interviewer see your passion for the job.

By following these tips, candidates can increase their chances of acing their interview for a Wet-End Operator position.Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet-End Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.