Are you gearing up for an interview for a Wet Finisher position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wet Finisher and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

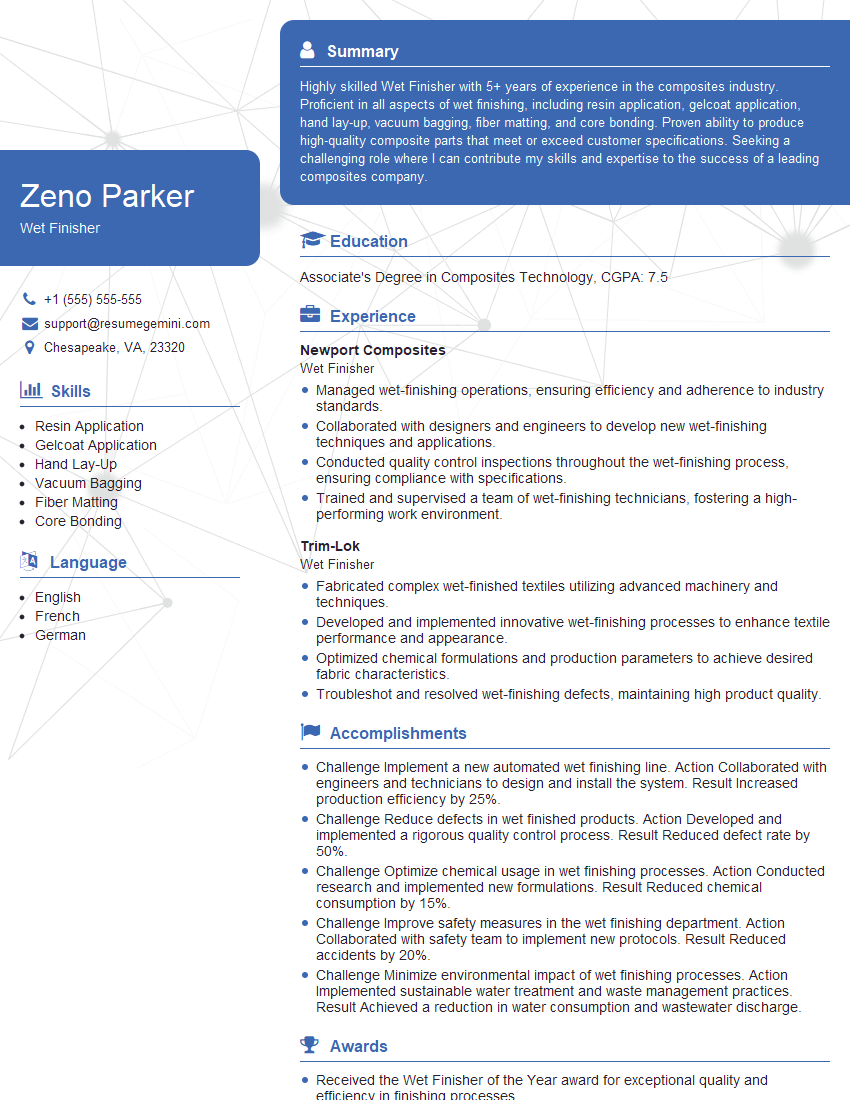

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Finisher

1. What are the key responsibilities of a Wet Finisher?

As a Wet Finisher, my responsibilities include:

- Applying wet finishes to surfaces to achieve desired textures and appearances

- Preparing surfaces by cleaning, sanding, and priming

- Applying finishes using brushes, rollers, or spray equipment

- Blending and smoothing finishes to ensure a uniform appearance

- Inspecting finished surfaces to ensure quality standards are met

2. What are the different types of wet finishes you have experience with?

Water-Based Finishes

- Latex paint

- Acrylic paint

- Water-based polyurethane

Oil-Based Finishes

- Oil-based paint

- Oil-based polyurethane

- Oil-based varnish

Specialty Finishes

- Epoxies

- Urethanes

- Lacquers

3. What are the factors that determine the choice of a particular wet finish?

The choice of wet finish depends on several factors, including:

- Surface type (wood, metal, concrete, etc.)

- Desired appearance (glossy, matte, textured, etc.)

- Exposure to elements (interior, exterior, moisture, etc.)

- Durability requirements

- Budget and time constraints

4. What is the process for preparing a surface for a wet finish?

Surface preparation is crucial for a successful wet finish.

- Clean the surface to remove dirt, grease, and other contaminants

- Sand the surface to smooth out any rough edges or imperfections

- Apply a primer to enhance adhesion and prevent the finish from absorbing into the surface

5. What are the different techniques used to apply wet finishes?

Wet finishes can be applied using various techniques, including:

- Brushing: Using a paintbrush to apply the finish in smooth, even strokes

- Rolling: Using a paint roller to apply the finish in a larger area, creating a smoother surface

- Spraying: Using a spray gun to apply the finish in a fine mist, providing a more even and consistent coating

6. How do you ensure a uniform appearance when applying wet finishes?

To achieve a uniform appearance:

- Apply thin, even coats of finish and allow each coat to dry completely before applying the next

- Use a consistent technique and pressure when applying the finish

- Sand lightly between coats to remove any imperfections or brush marks

- Inspect the finished surface under different lighting conditions to ensure uniformity

7. What are the common defects that can occur during wet finishing and how do you prevent them?

Defects

- Bubbling: Caused by trapped air or moisture. Prevented by proper surface preparation and applying thin coats

- Cracking: Caused by shrinkage or excessive thickness. Prevented by using the correct finish for the surface and applying thin coats

- Peeling: Caused by poor adhesion. Prevented by properly preparing the surface and using a compatible primer

8. How do you stay up-to-date with the latest techniques and materials in wet finishing?

To stay current:

- Attend industry conferences and workshops

- Read trade publications and online articles

- Consult with manufacturers and suppliers

- Experiment with new techniques and materials on test surfaces

9. What are your strengths and weaknesses as a Wet Finisher?

Strengths

- Highly skilled in applying various wet finishes to different surfaces

- Strong attention to detail and ability to achieve uniform and high-quality results

- Excellent problem-solving skills and ability to identify and correct defects

Weaknesses

- Limited experience with specialized or complex wet finishing techniques

- Can be slow and meticulous, especially when working on intricate or large-scale projects

10. Why are you interested in this Wet Finisher position?

I am eager to join your company because:

- Your reputation for producing high-quality finished products

- The opportunity to work with experienced professionals and expand my skills

- My passion for wet finishing and my desire to contribute to your team’s success

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Finisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Finisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wet Finisher is responsible for preparing and finishing plaster, stucco, or other cementitious materials on building surfaces. Their primary duties involve applying wet finishes to walls, ceilings, and other surfaces to create smooth and aesthetically pleasing surfaces. Wet Finishers play a crucial role in the construction industry, ensuring that interior and exterior surfaces meet required specifications and standards.

1. Surface Preparation

Wet Finishers begin by preparing the surface to be finished. This involves inspecting surfaces for defects, removing old or damaged materials, and repairing any underlying issues. They also apply bonding agents to ensure proper adhesion of the new finish.

2. Material Mixing and Application

Wet Finishers mix plaster, stucco, or other cementitious materials according to specified proportions. They apply the mixture using trowels, floats, and other tools to create a smooth and even surface. They may use different techniques such as floating, skimming, and sgraffito to achieve the desired finish.

3. Texturing and Smoothing

After applying the wet finish, Wet Finishers work to create the desired texture. They may use sponges, brushes, or trowels to create decorative effects such as knockdown, splatter, or knockdown textures. They also ensure that the surface is smooth and free of lumps or bumps.

4. Final Touches

Wet Finishers complete the finishing process by applying sealants or coatings to protect the surface from moisture and damage. They may also apply paint or other decorative finishes as required.

5. Maintenance and Repair

Wet Finishers may also be responsible for maintaining and repairing existing wet finishes. They identify and address issues such as cracks, chips, or discoloration, ensuring that surfaces remain in good condition.

Interview Tips

Preparing for an interview for a Wet Finisher position can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and the Role

Take the time to learn about the company you are applying to. Research their history, values, and recent projects. Familiarize yourself with the specific requirements of the Wet Finisher role, paying attention to keywords and responsibilities.

2. Highlight Your Skills and Experience

Emphasize your relevant skills and experience during the interview. Provide concrete examples of projects where you have successfully prepared and finished wet surfaces. Discuss your proficiency in using various tools and techniques.

3. Demonstrate Your Passion

Show the interviewer that you are passionate about wet finishing and have a genuine interest in the industry. Talk about your knowledge of different materials and techniques, and explain why you enjoy the work.

4. Be Prepared for Technical Questions

Expect to answer technical questions about wet finishing techniques, materials, and safety procedures. Be prepared to discuss your understanding of different types of finishes, application methods, and maintenance practices.

5. Practice Your Communication

Practice articulating your thoughts and ideas clearly and confidently. The interviewer will be looking for someone who can communicate effectively with clients, contractors, and other team members.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet Finisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!