Are you gearing up for a career in Wet Machine Cutter? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wet Machine Cutter and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

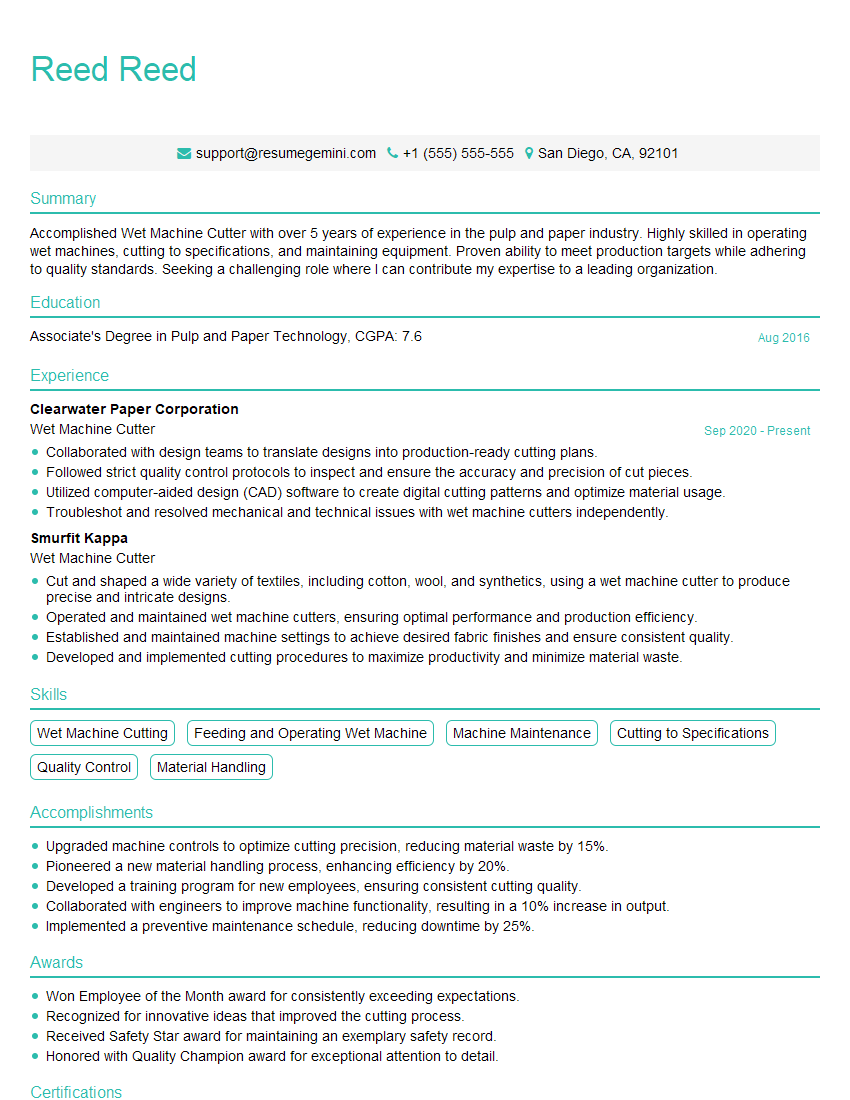

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Machine Cutter

1. What are the different types of wet machine cutters?

There are various types of wet machine cutters, including:

- Horizontal wet machine cutters: These cutters have the blade shaft positioned horizontally, which allows for cutting large pieces of material in a single pass.

- Vertical wet machine cutters: These cutters have the blade shaft positioned vertically, which is suitable for cutting smaller pieces of material or making intricate cuts.

- CNC wet machine cutters: These cutters are computer-controlled, providing high precision and accuracy in cutting operations.

- Manual wet machine cutters: These cutters are operated manually, requiring the operator to have a high level of skill and experience.

2. What are the essential safety precautions to follow when operating a wet machine cutter?

- Always wear appropriate personal protective equipment (PPE) such as safety glasses, hearing protection, and gloves.

- Ensure that the machine is properly grounded and that all guards are in place.

- Never reach over or behind the blade while the machine is in operation.

- Keep the work area clean and free of debris.

- Be aware of the potential for electrical hazards and take necessary precautions.

Maintenance and Inspection

- Regularly inspect the machine for any signs of wear or damage.

- Sharpen or replace blades as needed to ensure optimal performance and safety.

- Lubricate moving parts according to the manufacturer’s instructions.

3. How do you determine the correct blade for a specific cutting application?

Selecting the correct blade for a wet machine cutting application depends on several factors:

- Material being cut: Different materials have different cutting characteristics, and the blade must be appropriate for the material’s hardness, toughness, and thickness.

- Desired cut quality: The desired surface finish and precision of the cut will influence the choice of blade type and sharpness.

- Machine capabilities: The size and power of the wet machine cutter will determine the maximum blade size and type that can be used.

- Blade geometry: The blade’s geometry, including its tooth shape, rake angle, and clearance angle, affects the cutting efficiency and edge life.

4. How do you adjust the speed and feed rate of a wet machine cutter?

Adjusting the speed and feed rate of a wet machine cutter is crucial for optimizing cutting performance and achieving the desired results:

- Speed: The speed of the blade determines the number of cuts per minute. A higher speed can increase productivity, but it may also compromise cut quality and tool life.

- Feed rate: The feed rate controls the rate at which the material is fed into the blade. A higher feed rate can increase cutting efficiency, but it may also result in excessive wear on the blade and reduced cut quality.

- Material properties: The properties of the material being cut, such as its hardness and thickness, will influence the optimal speed and feed rate settings.

- Machine capabilities: The capabilities of the wet machine cutter, including its power and rigidity, will limit the range of speed and feed rate adjustments possible.

5. How do you troubleshoot common problems that may arise when operating a wet machine cutter?

Troubleshooting common problems that may arise when operating a wet machine cutter is essential for maintaining efficient and safe operation:

- Poor cut quality: This could be caused by a dull or damaged blade, incorrect speed or feed rate settings, or improper blade selection.

- Excessive vibration: This could indicate an unbalanced blade, loose components, or improper machine alignment.

- Overheating: This could be caused by excessive friction, dull blades, or inadequate lubrication.

- Electrical problems: These could include power outages, ground faults, or faulty wiring.

- Mechanical problems: These could include worn or damaged gears, bearings, or other components.

6. How do you maintain a wet machine cutter to ensure optimal performance and longevity?

- Regular cleaning: Keep the machine clean to prevent the accumulation of debris and coolant residue.

- Blade maintenance: Sharpen or replace blades as needed to maintain optimal cutting performance.

- Lubrication: Lubricate moving parts according to the manufacturer’s instructions to reduce friction and wear.

- Component inspection: Regularly inspect all components for signs of wear or damage and replace or repair as necessary.

- Coolant system maintenance: Ensure that the coolant system is functioning properly and that the coolant is clean and free of contaminants.

7. How do you calculate the cutting force required for a specific cutting operation?

Calculating the cutting force required for a specific cutting operation is essential for selecting the appropriate machine and tooling:

- Material properties: The material’s tensile strength, hardness, and thickness influence the cutting force.

- Blade geometry: The blade’s rake angle, clearance angle, and number of teeth affect the cutting force.

- Cutting speed and feed rate: The speed and feed rate at which the material is cut also impact the cutting force.

- Machine capabilities: The power and rigidity of the wet machine cutter limit the maximum cutting force that can be applied.

8. How do you ensure the accuracy and precision of cuts made with a wet machine cutter?

- Proper machine setup: Ensure that the machine is properly leveled and aligned to minimize errors.

- Accurate measurement: Use precise measuring tools to ensure that the material is correctly positioned for cutting.

- Sharp blades: Dull blades can lead to inaccurate cuts and poor surface finish.

- Controlled feed rate: Maintain a consistent feed rate to avoid отклонения in cut dimensions.

- Proper blade selection: Choose the appropriate blade type and geometry for the material being cut.

9. How do you optimize the cutting process for different materials, such as wood, metal, and plastic?

- Material properties: Understand the specific properties of the material, such as its hardness, toughness, and grain direction.

- Blade selection: Choose the appropriate blade type and geometry for the material being cut.

- Speed and feed rate adjustment: Adjust the speed and feed rate to optimize cutting efficiency and minimize material damage.

- Coolant selection: Use the appropriate coolant to lubricate the cutting process and prevent overheating.

- Specialized techniques: Apply specialized cutting techniques, such as climb cutting or back cutting, to achieve optimal results for specific materials.

10. How do you stay up-to-date with the latest advancements in wet machine cutting technology?

- Attend industry events and conferences

- Read technical journals and publications

- Participate in online forums and discussions

- Consult with experts and manufacturers

- Take advantage of training and certification programs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Machine Cutter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Machine Cutter‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wet Machine Cutter is responsible for operating and maintaining wet cutting machines to cut various materials such as metal, plastic, and rubber.

1. Machine Operation

Operate wet cutting machines according to specified procedures and safety protocols.

- Set up and adjust machine to desired specifications.

- Monitor machine operation and make adjustments as needed.

2. Material Handling

Load and unload materials onto the cutting machine in a safe and efficient manner.

- Position and secure materials for precise cutting.

- Follow proper material handling procedures to prevent damage to equipment and materials.

3. Quality Control

Inspect and measure cut pieces to ensure they meet specified quality standards.

- Conduct visual inspections and dimensional checks.

- Adjust machine settings and processes based on quality feedback.

4. Maintenance and Troubleshooting

Perform routine maintenance tasks to ensure optimal machine performance.

- Clean and lubricate machine components.

- Troubleshoot and resolve minor machine issues.

Interview Tips

Preparing for an interview as a Wet Machine Cutter is crucial to showcasing your skills and experience. Here are some tips to help you ace the interview:

1. Research the Company and Role

Thoroughly research the company and the specific Wet Machine Cutter role. Understand the company’s culture and the requirements of the position.

- Visit the company website and social media pages.

- Read industry news and articles to gain insights into the company’s operations.

2. Highlight Relevant Skills and Experience

Focus on highlighting your relevant skills and experience that align with the job responsibilities. Quantify your achievements whenever possible.

- Emphasize your experience in operating and maintaining wet cutting machines.

- Provide examples of how you have achieved quality results and maintained a high level of precision.

3. Practice Common Interview Questions

Practice answering common interview questions related to your responsibilities as a Wet Machine Cutter. This will help you feel more confident and prepared during the actual interview.

- Why are you interested in this role?

- Describe your experience in wet cutting operations.

4. Prepare Questions for the Interviewer

Asking well-thought-out questions at the end of the interview demonstrates your interest and engagement. Prepare questions that show you are eager to learn more about the company and the role.

- What are the company’s growth plans for the future?

- What opportunities are there for professional development?

Next Step:

Now that you’re armed with the knowledge of Wet Machine Cutter interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wet Machine Cutter positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini