Are you gearing up for a career in Wet Mixer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wet Mixer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

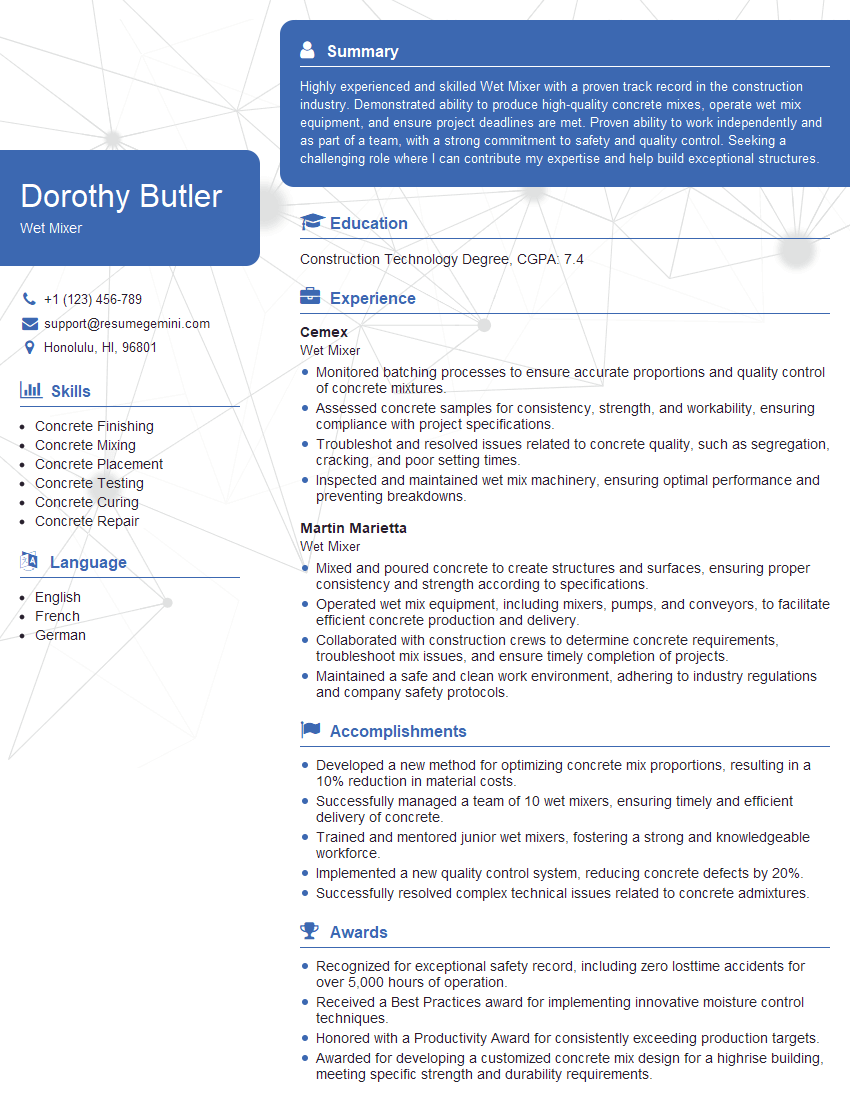

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Mixer

1. What are the different types of wet mixers?

- Batch Mixers: These mixers operate in batches, where a specific amount of materials is loaded into the mixer, mixed, and then discharged.

- Continuous Mixers: Continuous mixers operate continuously, with materials being added and discharged simultaneously.

- Tilting Drum Mixers: These mixers consist of a rotating drum that tilts to discharge the mixed materials.

- Paddle Mixers: Paddle mixers use rotating paddles to agitate and mix the materials.

- Planetary Mixers: Planetary mixers rotate a mixing head around a stationary bowl, ensuring thorough mixing.

2. What factors should be considered when selecting a wet mixer?

Capacity and Output

- The volume of materials to be mixed and the desired output rate

- Ensure the mixer has sufficient capacity to handle the required volume

Mix Quality and Time

- The desired consistency and homogeneity of the mixed materials

- Consider the mixing speed, agitation type, and mixing time to achieve the required mix quality

Materials and Properties

- The type of materials to be mixed (e.g., concrete, mortar, chemicals)

- The viscosity, abrasiveness, and compatibility of the materials with the mixer

Operational Environment

- The available space and layout for the mixer

- The environmental conditions (e.g., temperature, humidity) where the mixer will operate

3. What are the key maintenance tasks for a wet mixer?

- Regular cleaning and inspection to remove any material buildup or debris

- Lubrication of moving parts to ensure smooth operation and reduce wear

- Monitoring and calibration of sensors and controls to ensure accurate mixing and operation

- Replacement of worn or damaged components (e.g., blades, paddles, seals) as needed

- Scheduled maintenance and inspections to identify potential issues and prevent breakdowns

4. What safety precautions should be observed when operating a wet mixer?

- Wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection

- Ensure the mixer is properly grounded and electrically safe

- Never enter the mixing chamber while the mixer is operating

- Keep the mixer area clean and free of tripping hazards

- Follow all manufacturer’s instructions and safety guidelines

5. What are the common problems that can occur with wet mixers and how can they be resolved?

- Material Buildup: Regularly clean the mixer and ensure the correct mix ratio and consistency

- Motor Overheating: Check the motor for proper lubrication and ensure the mixer is not overloaded

- Uneven Mixing: Adjust the mixing speed, agitation type, or mixing time to optimize the mix quality

- Seal Leaks: Replace worn or damaged seals to prevent material leakage and contamination

- Electrical Faults: Ensure proper wiring, grounding, and electrical connections. Contact a qualified electrician if necessary

6. What are the advantages of using a wet mixer compared to other mixing methods?

- Efficient Mixing: Wet mixers provide thorough and consistent mixing due to their agitation mechanisms

- Controlled Hydration: In concrete mixing, wet mixers ensure proper water distribution and hydration of the cement

- Large Capacity: Wet mixers can handle large volumes of materials, making them suitable for industrial applications

- Versatile Applications: Wet mixers can be used for mixing various materials, including concrete, mortar, chemicals, and food products

- Automation: Modern wet mixers often feature automated controls and monitoring systems for improved efficiency and safety

7. What are the latest advancements in wet mixer technology?

- Self-Cleaning Mixers: These mixers have built-in cleaning systems to reduce downtime and maintenance

- High-Shear Mixers: These mixers provide intense agitation for rapid and uniform mixing

- Smart Mixers: Incorporating IoT and sensors, these mixers offer real-time monitoring and data analysis for optimized mixing processes

- Sustainable Mixers: Some mixers prioritize energy efficiency and reduced environmental impact

- Customized Mixers: Manufacturers offer tailored mixers designed for specific applications and requirements

8. How do you ensure the accuracy and consistency of the materials mixed in a wet mixer?

- Proper Calibration: Calibrate the mixer’s scales, sensors, and controls regularly to ensure accurate measurements

- Precise Weighing and Dispensing: Use precise weighing and dispensing systems to ensure the correct amount of materials is added

- Automated Mixing Cycles: Implement automated mixing cycles to minimize human error and maintain consistency

- Quality Control Checks: Perform regular quality control checks on the mixed materials to verify their properties and consistency

- Maintenance and Calibration Records: Maintain detailed records of calibration, maintenance, and inspections to ensure traceability

9. What is the difference between a single-shaft and a twin-shaft wet mixer?

- Single-Shaft Mixers: They have a single horizontal shaft with blades or paddles that rotate within a mixing drum

- Twin-Shaft Mixers: They have two parallel horizontal shafts, each with its own set of blades or paddles, providing more thorough mixing

- Advantages of Twin-Shaft Mixers: Better mixing efficiency, faster mixing times, and ability to handle heavier and more viscous materials

10. What is the importance of the mixing speed and time in a wet mixer?

- Mixing Speed: The speed of the mixer’s blades or paddles influences the intensity and efficiency of mixing

- Mixing Time: The duration of mixing is crucial for achieving the desired homogeneity and consistency of the mixed materials

- Optimizing Mixing Parameters: Proper selection of mixing speed and time ensures optimal mixing results, prevents overmixing, and minimizes energy consumption

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Mixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Mixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wet Mixer is responsible for the mixing, pouring, and finishing of concrete to create a variety of concrete products. The job typically includes operating heavy machinery and working in a physically demanding environment.

1. Operate Machinery

Wet Mixers operate and maintain a variety of heavy machinery, including concrete mixers, cement trucks, and conveyor belts.

- Operate concrete mixers to blend cement, sand, gravel, and water to create concrete.

- Drive cement trucks to transport concrete to construction sites.

- Use conveyor belts to move concrete from the mixer to the forms.

2. Finishing Concrete

Wet Mixers are responsible for finishing the concrete after it has been poured. This includes leveling, smoothing, and texturing the concrete.

- Level the concrete using a screed.

- Smooth the concrete using a trowel.

- Texture the concrete using a broom or other tools.

3. Maintaining Equipment

Wet Mixers are responsible for maintaining the equipment they use. This includes cleaning, lubricating, and repairing equipment as needed.

- Clean concrete mixers, cement trucks, and other equipment.

- Lubricate moving parts on equipment.

- Repair minor issues with equipment.

4. Safety and Compliance

Wet Mixers are responsible for following all safety regulations and adhering to quality control standards.

- Wear appropriate safety gear, including hard hats, gloves, and safety glasses.

- Follow all safety procedures and regulations.

- Inspect equipment regularly to ensure it is in good working condition.

Interview Tips

Preparing for a job interview can be stressful, but there are a few things you can do to increase your chances of success.

1. Research the Company and Industry

Before your interview, take some time to research the company you are applying to and the industry in which they operate. This will show the interviewer that you are interested in the position and that you have taken the time to learn about their business.

- Visit the company’s website to learn about their products, services, and culture.

- Read industry publications and news articles to stay up-to-date on the latest trends.

2. Practice Your Answers

One of the best ways to prepare for an interview is to practice your answers to common interview questions. This will help you feel more confident and prepared during the interview.

- Prepare answers to questions about your experience, skills, and qualifications.

- Practice answering questions about your strengths and weaknesses.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the office environment.

- For men, a suit or dress pants and a button-down shirt are always a good choice.

- For women, a skirt or dress suit, or dress pants and a blouse are all appropriate.

4. Be On Time

Punctuality is important, so make sure you arrive for your interview on time. This shows the interviewer that you are respectful of their time.

- Plan your route to the interview location in advance.

- Leave early to give yourself plenty of time to find parking and get to the interview room.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wet Mixer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.