Feeling lost in a sea of interview questions? Landed that dream interview for Wet Pour Supervisor but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wet Pour Supervisor interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

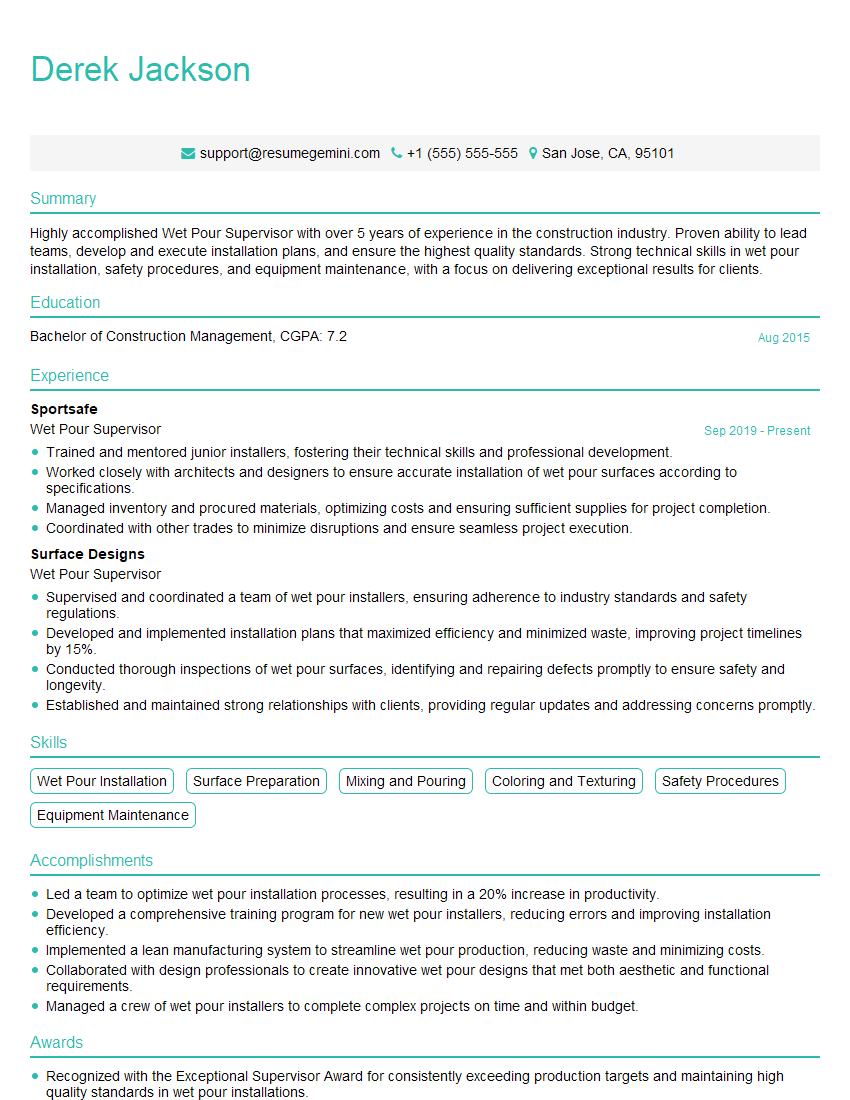

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Pour Supervisor

1. Describe the process of preparing a wet pour surface for installation?

The process of preparing a wet pour surface for installation involves several key steps:

- Site excavation and leveling: The site is excavated to the desired depth and leveled to ensure a uniform surface.

- Base course installation: A base course of crushed stone or recycled materials is compacted to create a stable foundation.

- Edging installation: Edging is installed around the perimeter of the surface to contain the wet pour material and prevent it from spreading.

- Drainage system installation: If necessary, a drainage system is installed to prevent water from pooling on the surface.

- Compaction and leveling: The base course is compacted using rollers to achieve the required density and smoothness.

2. What are the different types of wet pour materials and their properties?

Polyurethane-bound

- Durable and long-lasting

- Resistant to wear and tear

- Excellent slip resistance

- Available in a variety of colors

EPDM-bound

- Safer for children due to its lack of harmful chemicals

- UV-resistant and non-fading

- Cost-effective compared to polyurethane-bound surfaces

Acrylic-bound

- Quick and easy to install

- Ideal for temporary or low-impact areas

- Budget-friendly option

3. How do you determine the thickness and type of wet pour surface required for a specific application?

The thickness and type of wet pour surface required for a specific application are determined based on several factors:

- Intended use: The surface thickness is determined based on the anticipated level of foot traffic and activity.

- Fall height: For safety surfaces in playgrounds or other areas where falls may occur, the thickness is calculated according to industry standards to absorb impact.

- Subsurface conditions: The type of material used for the base course and the drainage system depends on the subsurface conditions.

- Budget: The type of wet pour material and the thickness of the surface are influenced by the project budget.

4. What are the common challenges faced during wet pour installation and how do you overcome them?

Common challenges faced during wet pour installation include:

- Weather conditions: Wet or cold weather can affect the curing process and the adherence of the material.

- Site conditions: Poor drainage or uneven surfaces can create problems during installation.

- Material quality: Using low-quality materials can lead to premature failure of the surface.

- Installer experience: Improper installation can result in voids, cracks, or delamination.

To overcome these challenges:

- Schedule installation during favorable weather conditions or take measures to protect the surface from the elements.

- Ensure proper site preparation, including drainage and leveling, to create a suitable foundation.

- Use high-quality materials from reputable suppliers.

- Hire experienced installers who are familiar with wet pour installation techniques.

5. How do you ensure the quality and durability of a wet pour surface?

To ensure the quality and durability of a wet pour surface:

- Proper installation practices: Follow manufacturer’s instructions and industry best practices for installation.

- Material selection: Use high-quality materials that meet industry standards for safety and durability.

- Regular maintenance: Implement a regular maintenance schedule to clean, inspect, and repair the surface as needed.

- Site inspections: Conduct periodic site inspections to identify any potential issues and address them promptly.

6. What are the safety considerations when working with wet pour materials?

- Respirators and protective gear: Use respirators to prevent inhaling harmful fumes and wear protective gear to avoid skin contact.

- Proper ventilation: Ensure adequate ventilation during installation to remove fumes and dust.

- Spill containment: Have spill containment measures in place to prevent materials from entering waterways or the environment.

- Training and supervision: Provide training to workers on proper handling and disposal of wet pour materials, and supervise their work closely.

7. How do you stay up-to-date on the latest advancements and best practices in the wet pour industry?

- Industry events and conferences: Attend industry events and conferences to learn about new technologies and best practices.

- Professional development courses: Take professional development courses or workshops to enhance knowledge and skills.

- Trade publications and online resources: Read trade publications and access online resources to stay informed about industry trends.

- Networking: Connect with other professionals in the field to exchange knowledge and experiences.

8. Can you describe a situation where you had to troubleshoot a problem during wet pour installation?

In a recent project, we encountered an issue where the surface was not curing properly. Through troubleshooting, we identified that the mix ratio of the materials was incorrect. We promptly corrected the mix ratio, and the surface cured successfully.

9. How do you ensure that the wet pour surface meets the specified performance requirements?

- Testing and documentation: Conduct tests to verify that the surface meets the required specifications for thickness, impact absorption, and other performance criteria.

- Certification: Obtain certifications from reputable organizations to demonstrate compliance with industry standards.

- Warranties and guarantees: Provide warranties and guarantees to customers to ensure their satisfaction with the surface.

10. How do you manage a team of installers and ensure their safety on a wet pour project?

To manage a team of installers and ensure their safety on a wet pour project:

- Clear communication: Establish clear lines of communication and provide detailed instructions to the team.

- Safety training: Provide comprehensive safety training to all team members.

- PPE enforcement: Enforce the use of personal protective equipment (PPE) and ensure that it is properly maintained.

- Site inspections: Conduct regular site inspections to identify potential hazards and address them promptly.

- Emergency preparedness: Develop and implement emergency procedures to respond to accidents or spills.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Pour Supervisor.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Pour Supervisor‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wet Pour Supervisor is responsible for overseeing the installation and maintenance of wet pour surfaces. They ensure that the surfaces are installed to the highest quality standards and meet all safety regulations. The Supervisor also provides training to new employees on the proper installation and maintenance techniques.

1. Installation of Wet Pour Surfaces

The Wet Pour Supervisor is responsible for the installation of wet pour surfaces. This includes preparing the site, mixing and pouring the material, and finishing the surface. They must ensure that the surface is installed to the correct thickness and density, and that it meets all safety regulations.

- Prepare the site for the installation of the wet pour surface.

- Mix and pour the wet pour material.

- Finish the surface to the correct thickness and density.

- Ensure that the surface meets all safety regulations.

2. Maintenance of Wet Pour Surfaces

The Wet Pour Supervisor is also responsible for the maintenance of wet pour surfaces. This includes cleaning the surface, repairing any damage, and resealing the surface as needed. They must ensure that the surface is safe and in good condition at all times.

- Clean the wet pour surface.

- Repair any damage to the surface.

- Reseal the surface as needed.

- Ensure that the surface is safe and in good condition at all times.

3. Training of New Employees

The Wet Pour Supervisor is also responsible for training new employees on the proper installation and maintenance techniques for wet pour surfaces. They must ensure that new employees are able to install and maintain wet pour surfaces to the highest quality standards.

- Train new employees on the proper installation and maintenance techniques for wet pour surfaces.

- Ensure that new employees are able to install and maintain wet pour surfaces to the highest quality standards.

4. Safety

The Wet Pour Supervisor must ensure that all safety regulations are followed during the installation and maintenance of wet pour surfaces. They must also ensure that all employees are aware of the safety hazards associated with working with wet pour materials.

- Ensure that all safety regulations are followed during the installation and maintenance of wet pour surfaces.

- Ensure that all employees are aware of the safety hazards associated with working with wet pour materials.

Interview Tips

Preparing for a job interview can be a daunting task, but there are a few things you can do to increase your chances of success. Here are a few interview tips for the position of Wet Pour Supervisor:

1. Research the Company

Before you go to your interview, it is important to research the company. This will help you understand the company’s culture, values, and goals. It will also help you answer questions about the company during your interview.

- Visit the company’s website.

- Read articles about the company in trade publications.

- Talk to people who work for the company.

2. Practice Answering Interview Questions

One of the best ways to prepare for an interview is to practice answering common interview questions. This will help you feel more confident and prepared during your interview.

- Write down a list of common interview questions.

- Practice answering these questions out loud.

- Get feedback from a friend or family member.

3. Dress Professionally

First impressions matter, so it is important to dress professionally for your interview. This means wearing clean, pressed clothes that are appropriate for the position you are applying for.

- Wear a suit or dress pants and a button-down shirt.

- Make sure your clothes are clean and pressed.

- Avoid wearing casual clothing, such as jeans or t-shirts.

4. Be Punctual

Punctuality is important for any job interview, but it is especially important for a position in the construction industry. Arriving late for your interview will show the interviewer that you are not serious about the position.

- Plan your route ahead of time and leave yourself extra time for traffic.

- If you are running late, call the interviewer and let them know.

- Do not arrive more than 15 minutes early for your interview.

5. Be Enthusiastic

Interviewers are looking for candidates who are enthusiastic about the position they are applying for. Show the interviewer that you are excited about the opportunity to work for their company.

- Smile and make eye contact with the interviewer.

- Speak clearly and confidently.

- Show the interviewer that you are passionate about the construction industry.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet Pour Supervisor interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.