Feeling lost in a sea of interview questions? Landed that dream interview for Wet Process Head Miller but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wet Process Head Miller interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

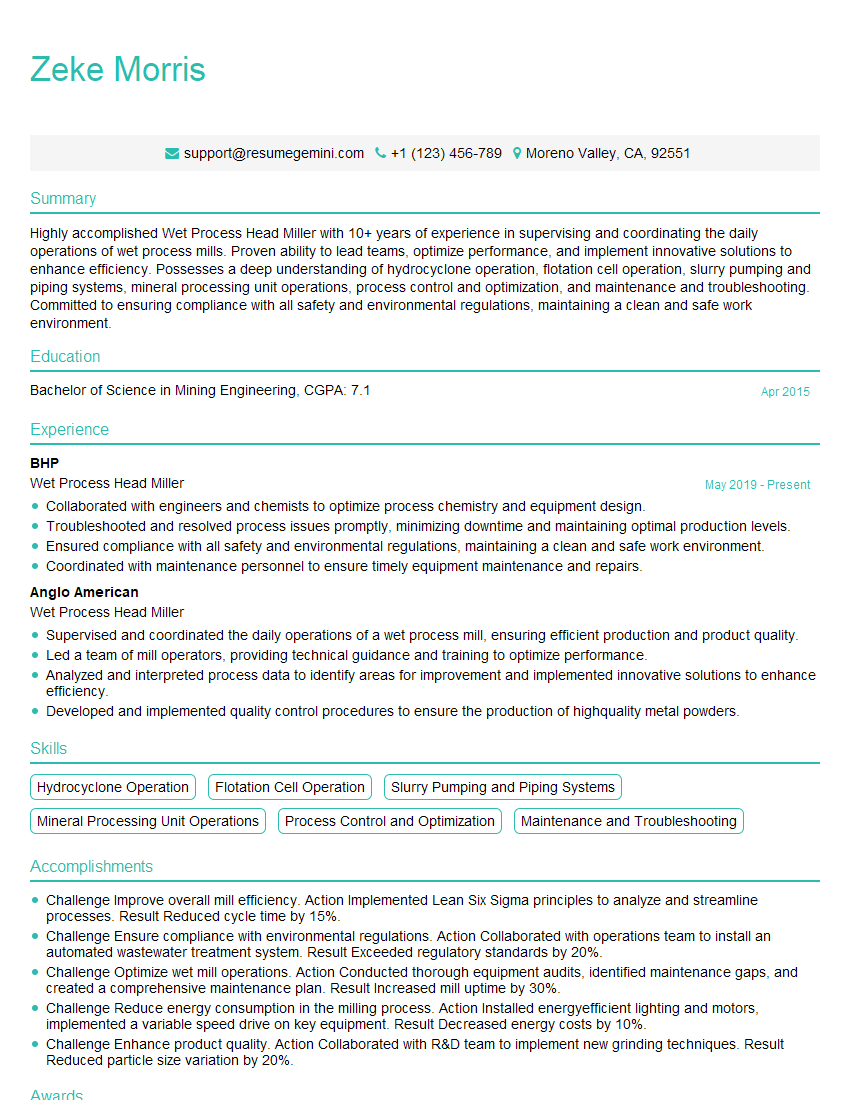

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Process Head Miller

1. What are the key responsibilities of a Wet Process Head Miller?

As a Wet Process Head Miller, my primary responsibilities include:

- Overseeing and managing the entire wet process operation, from raw material preparation to finished product packaging.

- Optimizing production processes to maximize efficiency and minimize waste.

- Ensuring compliance with all food safety and quality standards.

- Supervising and motivating a team of operators.

- Conducting regular performance evaluations and providing training to enhance team capabilities.

2. What are the challenges you expect to encounter in this role?

Production Efficiency

- Balancing production volume with maintaining high-quality standards.

- Optimizing equipment utilization to minimize downtime and increase productivity.

Food Safety and Quality

- Ensuring strict adherence to food safety regulations and industry best practices.

- Implementing rigorous quality control measures to maintain product consistency.

Team Management

- Motivating and leading a diverse team of operators.

- Providing effective training and ongoing support to enhance team performance.

3. How do you monitor and control the quality of finished products?

I implement a comprehensive quality control system that encompasses:

- Regular sampling and testing of raw materials and finished products.

- Visual inspections to monitor product appearance and consistency.

- Sensory evaluation to assess taste, texture, and aroma.

- Statistical process control to identify and minimize product variability.

- Collaboration with the quality assurance department to ensure compliance with industry standards.

4. What are the latest technological advancements in the wet processing industry?

The wet processing industry is constantly evolving, and I stay abreast of the latest technological advancements, including:

- Automated process control systems to optimize production efficiency and reduce human error.

- Advanced sensing technologies for real-time monitoring of product quality.

- Artificial intelligence and machine learning algorithms for predictive maintenance and product defect detection.

5. How do you ensure the safety of your team and the production environment?

Safety is paramount in my operations. I prioritize the following measures:

- Regular safety training and awareness programs for all employees.

- Implementation of strict adherence to safety protocols and guidelines.

- Inspection and maintenance of equipment and machinery to minimize potential hazards.

- Establishment of emergency response plans and regular drills.

- Collaboration with the safety department to ensure compliance with all safety regulations.

6. How do you handle production line breakdowns and emergencies?

In the event of production line breakdowns or emergencies, I follow a systematic approach:

- Assess the situation and identify the root cause of the issue.

- Coordinate with the maintenance team to resolve the breakdown or emergency efficiently.

- Communicate with management and other stakeholders to keep them informed.

- Document the incident and implement corrective actions to prevent similar occurrences in the future.

7. How do you optimize process efficiency and reduce waste?

I employ data analysis and continuous improvement techniques to optimize process efficiency and reduce waste:

- Monitor production data and identify areas for improvement.

- Implement process modifications and automation to streamline operations.

- Train operators on best practices to minimize waste and improve productivity.

- Collaborate with suppliers to optimize raw material quality and reduce material waste.

8. How do you stay updated on industry trends and best practices?

I actively seek professional development opportunities to stay informed:

- Attend industry conferences, workshops, and seminars.

- Read trade publications and research articles.

- Network with industry professionals and colleagues.

- Explore new technologies and innovative solutions.

9. How do you motivate your team and encourage professional growth?

I believe in empowering and motivating my team:

- Recognize and reward employee achievements.

- Provide opportunities for professional development and training.

- Foster a collaborative and open work environment.

- Set clear expectations and provide regular feedback.

- Encourage team members to share ideas and contribute to process improvements.

10. What are your strengths and weaknesses as a Wet Process Head Miller?

Strengths

- Proven track record of optimizing wet process operations and increasing productivity.

- Strong understanding of food safety regulations and quality control principles.

- Excellent leadership and communication skills, with a proven ability to motivate and develop teams.

- Expertise in process improvement and waste reduction.

- Ability to stay updated on industry trends and adopt innovative solutions.

Weaknesses

- Limited experience in managing large-scale production operations.

- Not fluent in Spanish, which could limit my ability to communicate effectively with some team members.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Process Head Miller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Process Head Miller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Wet Process Head Miller plays a critical role in the production of high-quality paper products, overseeing the wet process department and ensuring efficient operations. Key responsibilities include:

1. Production Management

Manage the wet process department, including production schedules, equipment maintenance, and quality control. Ensure smooth and efficient operations, meeting production targets while maintaining high standards.

- Develop and implement production plans to optimize output and efficiency.

- Monitor and control production processes to maintain product quality and consistency.

2. Equipment Operation and Maintenance

Operate and maintain a variety of wet process equipment, including pulp preparation, stock preparation, and paper machines. Ensure equipment is running smoothly and efficiently, performing regular inspections and preventive maintenance.

- Troubleshoot and resolve equipment issues to minimize downtime and maintain production.

- Stay up-to-date on new technologies and best practices in the industry to optimize equipment performance.

3. Quality Control

Implement and monitor quality control procedures throughout the wet process department. Inspect raw materials, monitor production processes, and conduct regular testing to ensure adherence to product specifications.

- Identify and correct any quality deviations promptly.

- Work closely with the quality control team to maintain high quality standards.

4. Team Leadership and Training

Supervise and lead a team of wet process operators. Provide guidance, training, and support to enhance team performance and development.

- Motivate and empower team members to achieve organizational goals.

- Identify and address training needs to improve team skills and knowledge.

5. Continuous Improvement

Continuously seek ways to enhance the efficiency and effectiveness of the wet process department. Identify and implement process improvements, reduce waste, and optimize resource utilization.

- Stay abreast of industry trends and best practices to drive innovation and improvement.

- Collaborate with other departments to identify opportunities for inter-departmental optimization.

Interview Tips

To ace the interview for a Wet Process Head Miller position, candidates should be well-prepared and demonstrate their expertise in the field. Here are some tips to help:

1. Research the Company and Position

Thoroughly research the company and the specific role you are applying for. Understand their products, processes, and company culture. This knowledge will help you align your skills and experience with their needs and demonstrate your genuine interest in the position.

- Visit the company website, read industry publications, and connect with current or former employees.

- Identify the key responsibilities and requirements of the role, and prepare examples that showcase your relevant skills.

2. Highlight Relevant Skills and Experience

Emphasize your hands-on experience in wet process operations, equipment maintenance, and quality control. Quantify your accomplishments and provide specific examples of how you have contributed to production efficiency, improved product quality, or implemented process improvements.

- Discuss your ability to troubleshoot and resolve equipment issues quickly and effectively.

- Highlight your knowledge of papermaking processes and your expertise in managing and optimizing production.

3. Demonstrate Leadership and Teamwork Abilities

Showcase your leadership and teamwork skills. Explain how you have successfully supervised and motivated teams, facilitated training, and fostered a collaborative work environment. Emphasize your ability to work effectively with colleagues from diverse backgrounds and levels.

- Provide examples of how you have handled conflicts and resolved issues within your team.

- Describe how you have successfully implemented new processes or technologies in a team setting.

4. Promote Continuous Improvement Mindset

Convey your commitment to continuous improvement. Discuss your track record of identifying and implementing process enhancements and your willingness to adopt new technologies and best practices. Explain how you have contributed to reducing waste, increasing efficiency, or improving product quality.

- Share examples of how you have identified and resolved bottlenecks in production processes.

- Discuss your willingness to learn and adapt to new challenges and embrace innovation.

5. Prepare for Industry-Specific Questions

Be prepared to answer industry-specific questions related to wet process operations, papermaking technologies, and quality control standards. This demonstrates your technical knowledge and understanding of the field.

- Discuss your experience with different types of pulp and paper products, and their production processes.

- Explain your understanding of quality control parameters and testing methods used in the paper industry.

Next Step:

Now that you’re armed with the knowledge of Wet Process Head Miller interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wet Process Head Miller positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini