Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wet Suit Gluer interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wet Suit Gluer so you can tailor your answers to impress potential employers.

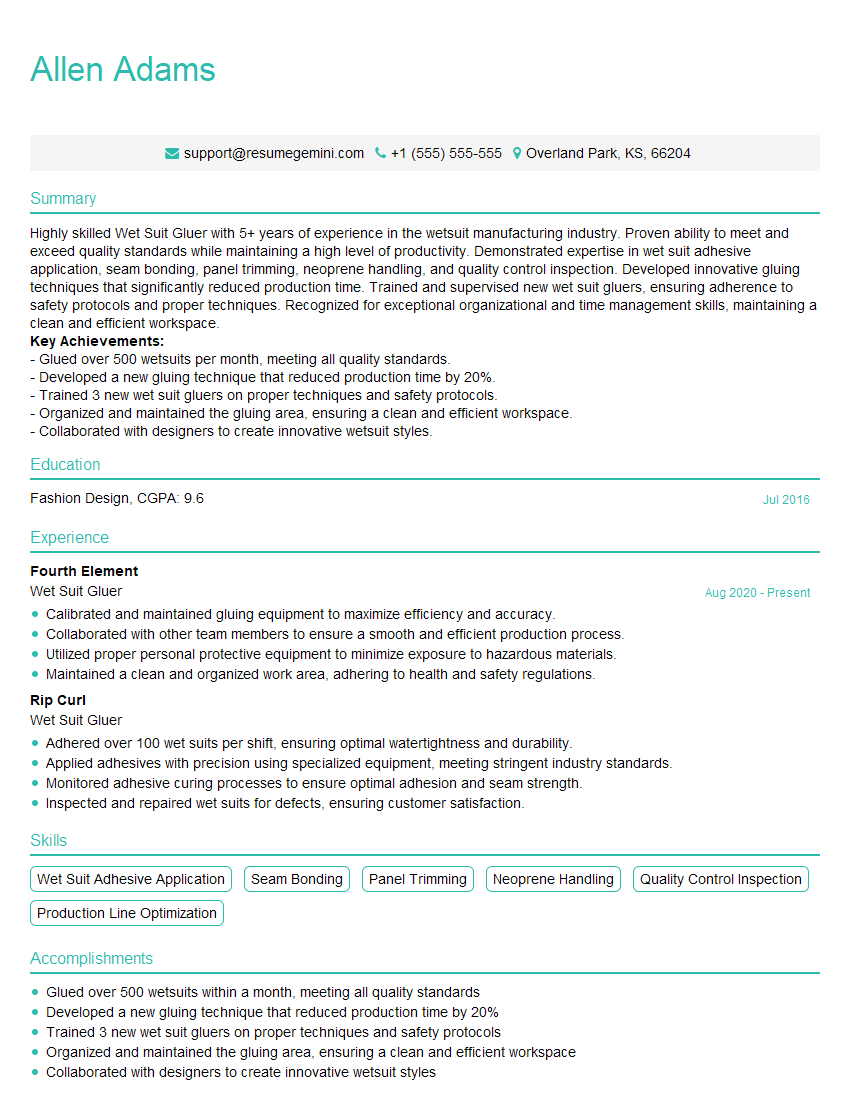

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Suit Gluer

1. What are the different types of wet suit glue?

- Neoprene cement: This is the most common type of wet suit glue and is made from a blend of rubber and solvents. It is strong and durable, but it can be difficult to work with and can take a long time to dry.

- Contact cement: This type of glue is made from a blend of rubber and resins. It is very strong and dries quickly, but it can be difficult to reposition once it has been applied.

- Weldwood contact cement: This is a type of contact cement that is specifically designed for use on wet suits. It is strong and durable, and it dries quickly.

2. What are the steps involved in gluing a wet suit?

subheading of the answer

- Clean the surfaces to be glued with a solvent.

- Apply a thin coat of glue to both surfaces.

- Allow the glue to dry for a few minutes.

- Press the surfaces together and hold them in place for a few minutes.

subheading of the answer

- Allow the glue to cure for at least 24 hours before using the wet suit.

- Make sure to wear gloves and a respirator when working with wet suit glue, as it can be harmful to your health.

3. What are the most common problems that can occur when gluing a wet suit?

- The glue is not strong enough and the seam fails.

- The glue is too thick and it creates a bulky seam.

- The glue is not applied evenly and it creates a weak seam.

4. What are the different types of wet suit repair kits?

- Basic repair kits: These kits typically include a small tube of glue, a few patches, and a pair of scissors.

- Deluxe repair kits: These kits typically include a larger tube of glue, a variety of patches, a pair of scissors, and a seam ripper.

5. What are the steps involved in repairing a wet suit?

subheading of the answer

- Clean the area to be repaired with a solvent.

- Apply a thin coat of glue to the patch and to the area to be repaired.

- Allow the glue to dry for a few minutes.

- Press the patch into place and hold it for a few minutes.

subheading of the answer

- Allow the glue to cure for at least 24 hours before using the wet suit.

- Make sure to wear gloves and a respirator when working with wet suit glue, as it can be harmful to your health.

6. What are the most common problems that can occur when repairing a wet suit?

- The patch is not strong enough and the seam fails.

- The glue is too thick and it creates a bulky seam.

- The glue is not applied evenly and it creates a weak seam.

7. What are the different types of wet suit seams?

- Flatlock seam: This is the most common type of wet suit seam. It is made by sewing two pieces of neoprene together with a flat stitch.

- Blind stitch seam: This type of seam is made by sewing two pieces of neoprene together with a blind stitch. This creates a more waterproof seam than a flatlock seam.

- Glued seam: This type of seam is made by gluing two pieces of neoprene together. This creates a very strong seam, but it can be difficult to repair.

8. What are the advantages and disadvantages of different wet suit seams?

subheading of the answer

- Flatlock seam: Advantages: strong, easy to repair, inexpensive. Disadvantages: not as waterproof as other seams.

- Blind stitch seam: Advantages: waterproof, strong. Disadvantages: difficult to repair, expensive.

- Glued seam: Advantages: strong, waterproof. Disadvantages: difficult to repair, expensive.

9. What are the different types of wet suit materials?

- Neoprene: This is the most common type of wet suit material. It is a synthetic rubber that is waterproof and insulating.

- Lycra: This is a type of synthetic fabric that is stretchy and comfortable. It is often used in wet suits for the arms and legs.

- Nylon: This is a type of synthetic fabric that is strong and durable. It is often used in wet suits for the outer layer.

10. What are the advantages and disadvantages of different wet suit materials?

subheading of the answer

- Neoprene: Advantages: waterproof, insulating. Disadvantages: not as flexible as other materials, can be bulky.

- Lycra: Advantages: stretchy, comfortable. Disadvantages: not as waterproof as neoprene, can be easily damaged.

- Nylon: Advantages: strong, durable. Disadvantages: not as flexible as other materials, can be uncomfortable.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Suit Gluer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Suit Gluer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wet Suit Gluers play a pivotal role in the production of wet suits. Their primary duties encompass:

1. Adhesives Management

Meticulously applying adhesives to various components of wet suits, ensuring accurate placement and uniform distribution.

- Selecting the appropriate adhesive for specific materials and applications.

- Maintaining proper storage and handling of adhesives to preserve their effectiveness.

2. Suit Component Assembly

Skillfully aligning and joining wet suit components, such as panels, seams, and zippers, according to design specifications.

- Using specialized tools and techniques to create secure and durable bonds.

- Inspecting assembled components for defects and ensuring they meet quality standards.

3. Quality Control

Thoroughly inspecting finished wet suits to verify their compliance with specifications and performance expectations.

- Conducting visual and tactile examinations to identify any imperfections or weaknesses.

- Implementing corrective measures to rectify any detected discrepancies.

4. Equipment Maintenance

Maintaining and cleaning specialized equipment used in the gluing process, ensuring its optimal functioning.

- Performing regular inspections and calibrations to prevent equipment breakdowns.

- Troubleshoot and resolve any technical issues that may arise.

Interview Tips

To excel in a Wet Suit Gluer interview, it is essential to prepare thoroughly and demonstrate your skills and knowledge effectively.

1. Research the Industry and Company

Familiarize yourself with the wet suit industry and specific company values, products, and processes.

- This knowledge will enable you to tailor your answers and highlight your understanding of the role’s context.

- Visit the company website, read industry articles, and connect with professionals on LinkedIn.

2. Highlight Your Technical Skills

Emphasize your proficiency in adhesives application, component assembly, and quality control techniques.

- Provide specific examples of projects where you successfully utilized these skills.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact.

3. Showcase Your Attention to Detail

Stress your meticulous attention to detail and ability to produce high-quality work.

- Describe instances where you identified and corrected errors in your own work or in the work of others.

- Explain how your commitment to quality ensures that all wet suits meet the highest standards.

4. Practice Your Communication Skills

Interviews require clear and concise communication. Prepare your answers to common interview questions.

- Practice presenting your qualifications and experiences in a confident and engaging manner.

- Speak clearly, maintain eye contact, and use body language that conveys professionalism.

Next Step:

Now that you’re armed with interview-winning answers and a deeper understanding of the Wet Suit Gluer role, it’s time to take action! Does your resume accurately reflect your skills and experience for this position? If not, head over to ResumeGemini. Here, you’ll find all the tools and tips to craft a resume that gets noticed. Don’t let a weak resume hold you back from landing your dream job. Polish your resume, hit the “Build Your Resume” button, and watch your career take off! Remember, preparation is key, and ResumeGemini is your partner in interview success.