Are you gearing up for an interview for a Wet Wash Assembler position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wet Wash Assembler and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

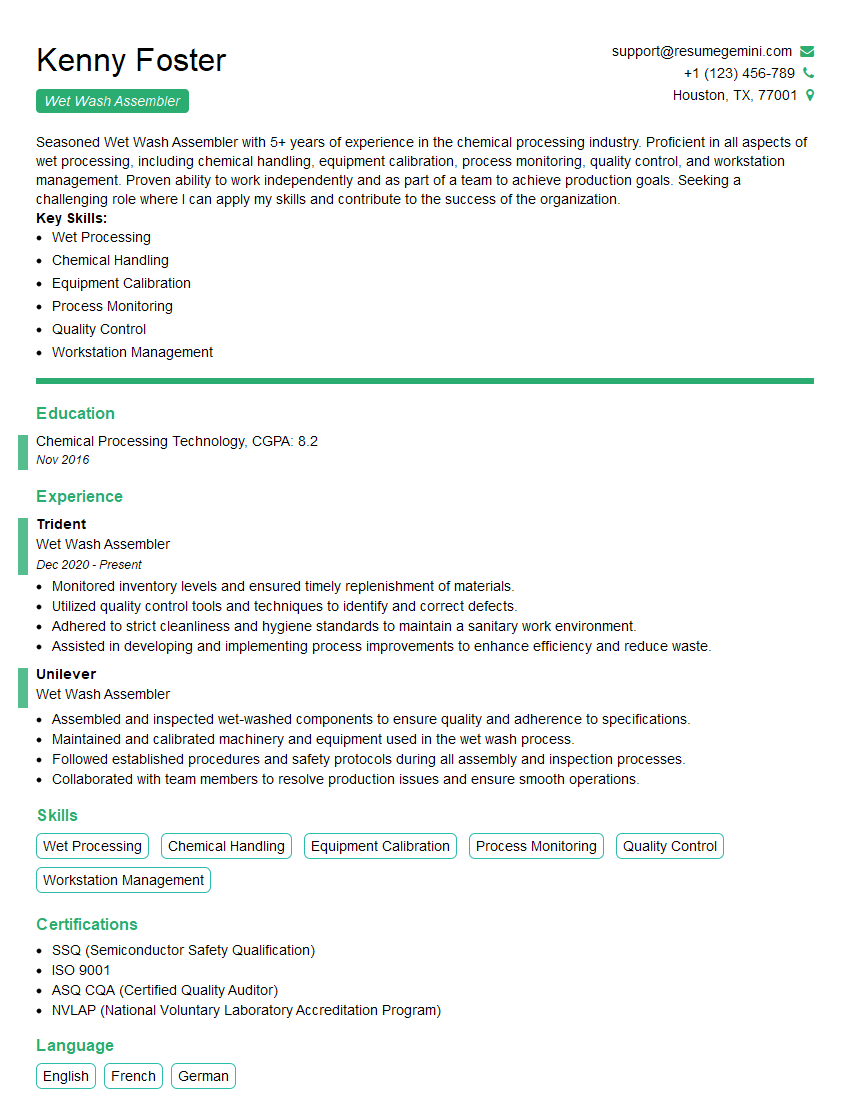

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wet Wash Assembler

1. What are the key responsibilities of a Wet Wash Assembler?

The key responsibilities of a Wet Wash Assembler include:

- Assemble and join components using wet wash techniques.

- Operate and maintain wet wash assembly equipment.

- Inspect and test assembled components to ensure they meet specifications.

- Follow safety protocols and procedures.

- Maintain a clean and organized work area.

- Work independently and as part of a team.

2. What are the different wet wash assembly techniques?

The different wet wash assembly techniques include:

Solvent cleaning

- Using solvents to remove contaminants from components.

- Requires specialized equipment and ventilation systems.

Aqueous cleaning

- Using water-based solutions to clean components.

- Less hazardous than solvent cleaning.

Ultrasonic cleaning

- Using high-frequency sound waves to remove contaminants from components.

- Effective for cleaning complex or delicate components.

3. What are the different types of wet wash assembly equipment?

The different types of wet wash assembly equipment include:

- Wet wash tanks

- Ultrasonic cleaners

- Conveyor systems

- Drying ovens

- Inspection stations

4. What are the challenges of working as a Wet Wash Assembler?

The challenges of working as a Wet Wash Assembler include:

- Working in a wet and potentially hazardous environment.

- Repetitive and physically demanding work.

- Meeting tight production deadlines.

- Working with chemicals and solvents.

- Maintaining a clean and organized work area.

5. What are the safety protocols and procedures that must be followed when working as a Wet Wash Assembler?

The safety protocols and procedures that must be followed when working as a Wet Wash Assembler include:

- Wearing appropriate personal protective equipment (PPE).

- Following safe work practices when handling chemicals and solvents.

- Maintaining a clean and organized work area.

- Reporting any accidents or incidents immediately.

- Receiving regular safety training.

6. What are the quality control procedures that must be followed when working as a Wet Wash Assembler?

The quality control procedures that must be followed when working as a Wet Wash Assembler include:

- Inspecting and testing assembled components to ensure they meet specifications.

- Maintaining records of inspection and test results.

- Reporting any defects or non-conformances immediately.

- Following corrective action procedures.

- Receiving regular quality training.

7. What are the maintenance procedures that must be followed when working as a Wet Wash Assembler?

The maintenance procedures that must be followed when working as a Wet Wash Assembler include:

- Cleaning and inspecting equipment regularly.

- Lubricating and adjusting equipment as needed.

- Performing preventive maintenance tasks.

- Reporting any equipment problems immediately.

- Receiving regular maintenance training.

8. What are the troubleshooting procedures that must be followed when working as a Wet Wash Assembler?

The troubleshooting procedures that must be followed when working as a Wet Wash Assembler include:

- Identifying the problem.

- Determining the cause of the problem.

- Taking corrective action to solve the problem.

- Testing the solution to ensure it works.

- Documenting the problem and the solution.

9. What are the communication skills that are required for a Wet Wash Assembler?

The communication skills that are required for a Wet Wash Assembler include:

- Ability to communicate effectively with supervisors, co-workers, and customers.

- Ability to read and understand technical documentation.

- Ability to write clear and concise reports.

- Ability to give and receive feedback.

- Ability to work in a team environment.

10. What are the interpersonal skills that are required for a Wet Wash Assembler?

The interpersonal skills that are required for a Wet Wash Assembler include:

- Ability to work independently and as part of a team.

- Ability to follow instructions and work under supervision.

- Ability to meet deadlines and work under pressure.

- Ability to maintain a positive attitude and work ethic.

- Ability to resolve conflicts and build relationships.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wet Wash Assembler.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wet Wash Assembler‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wet Wash Assemblers are responsible for a variety of tasks essential to ensuring the smooth operation of any manufacturing plant. The assembler is responsible for assembling and disassembling complex mechanisms that require specialized knowledge and skills.

1. Assembling and disassembling equipment

Wet Wash Assemblers must be able to correctly assemble and disassemble complex equipment, including electronic components, mechanical parts, and machinery. This requires a deep understanding of how each component works and how it fits together.

2. Inspecting and testing equipment

Once assembled, Wet Wash Assemblers must inspect and test equipment to ensure it is functioning properly. This includes conducting visual inspections, running diagnostic tests, and making necessary adjustments.

3. Troubleshooting and repairing equipment

Wet Wash Assemblers must be able to identify and resolve common problems with equipment. This requires knowledge of electrical, mechanical, and hydraulic systems, as well as the ability to use diagnostic tools and equipment.

4. Maintaining equipment records

Wet Wash Assemblers are responsible for maintaining accurate records of all equipment maintenance and repairs. This includes keeping track of parts used, labor hours, and any other relevant information.

Interview Tips

Interviewing for a Wet Wash Assembler position can be challenging, but with the right preparation, you can increase your chances of success. Here are a few tips to help you ace your interview:

1. Research the company and the position

Before you go on an interview, take the time to learn as much as you can about the company and the position you are applying for. This will help you answer questions intelligently and demonstrate your interest in the role.

2. Practice your answers to common interview questions

There are a number of common interview questions that you may be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice answering these questions in advance so that you can deliver your responses confidently and clearly.

3. Bring a portfolio of your work

If you have any examples of your work that you can bring to the interview, do so. This could include photos of projects you have completed, samples of reports you have written, or examples of your coding skills.

4. Be prepared to talk about your experience

The interviewer will want to know about your experience and qualifications, so be prepared to talk about your previous jobs, your education, and any relevant skills you have.

5. Be enthusiastic and positive

Interviewers are looking for candidates who are enthusiastic about the position and who have a positive attitude. Be sure to project a positive image and demonstrate your eagerness to learn and grow.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wet Wash Assembler interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!