Are you gearing up for an interview for a Wheel Buffer position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wheel Buffer and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

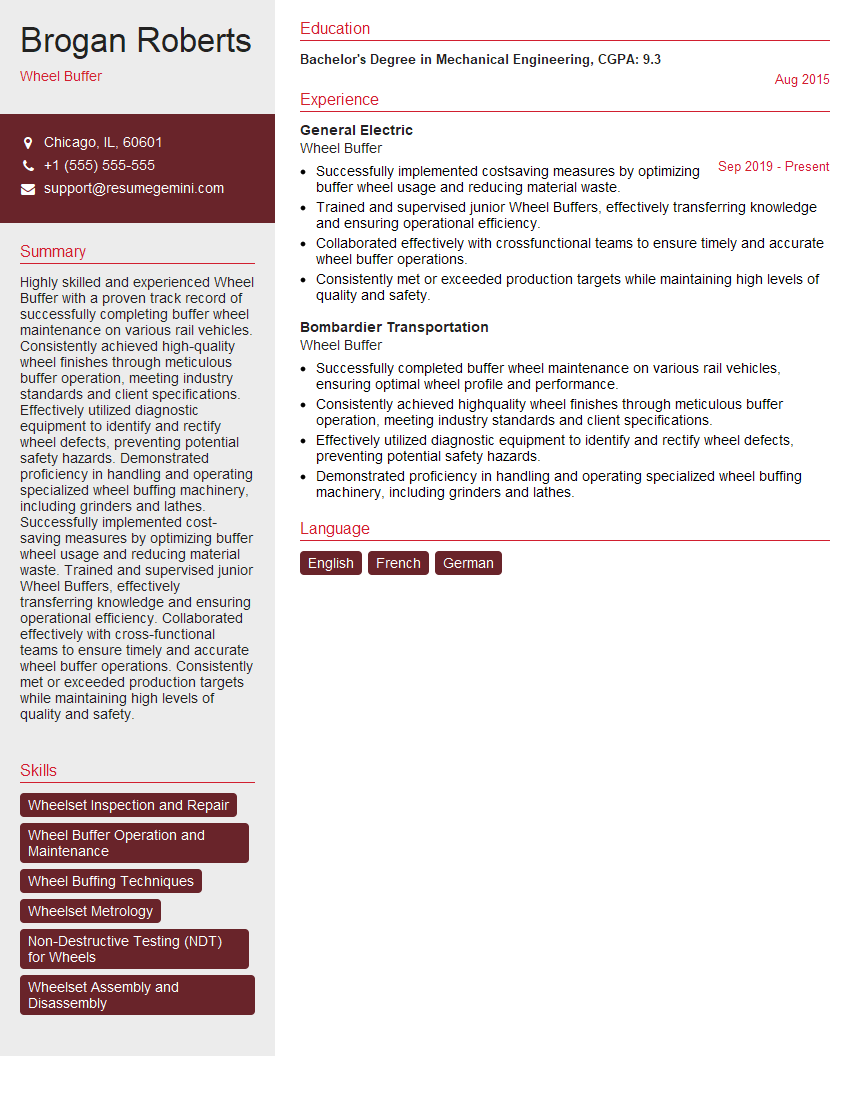

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Buffer

1. How would you describe the process of wheel buffing?

Wheel buffing is a process of using a rotating abrasive wheel to remove scratches and other surface imperfections from a metal surface. It can be used to create a variety of finishes, from a matte to a high polish. The process is typically carried out by hand, but automated systems are also available.

- The first step in wheel buffing is to select the appropriate abrasive wheel. The type of wheel used will depend on the material being buffed and the desired finish.

- Once the wheel has been selected, it is mounted on a buffing machine. The machine is then started and the wheel is brought into contact with the metal surface.

- The wheel is rotated at a high speed and the abrasive particles on the wheel remove the surface imperfections from the metal.

- The buffing process is continued until the desired finish is achieved.

2. What are the different types of abrasive wheels used in wheel buffing?

Ceramic wheels

- Ceramic wheels are made from a mixture of ceramic oxides, such as aluminum oxide and zirconium oxide.

- They are very hard and durable, and can be used to remove heavy scratches and other surface imperfections.

Cloth wheels

- Cloth wheels are made from a variety of materials, such as cotton, canvas, and linen.

- They are less abrasive than ceramic wheels, and are used for polishing and finishing surfaces.

Felt wheels

- Felt wheels are made from wool or other natural fibers.

- They are very soft and are used for polishing delicate surfaces.

3. How do you determine the correct speed for wheel buffing?

The correct speed for wheel buffing depends on the material being buffed and the desired finish. Generally, a higher speed will produce a more aggressive cut, while a lower speed will produce a finer finish.

- For soft materials, such as aluminum, a lower speed is typically used.

- For harder materials, such as steel, a higher speed is typically used.

- The desired finish will also affect the speed. A higher speed will produce a more polished finish, while a lower speed will produce a more matte finish.

4. What are the safety precautions that should be taken when wheel buffing?

Wheel buffing can be a hazardous process if proper safety precautions are not taken. The following are some of the most important safety precautions to follow:

- Wear appropriate safety gear, including gloves, safety glasses, and a dust mask.

- Keep the buffing machine in good condition and make sure that all guards are in place.

- Never operate the buffing machine without proper training.

- Be aware of the potential for sparks and fire, and have a fire extinguisher nearby.

5. What are some common problems that can occur when wheel buffing?

- Chattering: This is a vibration that can occur when the wheel is not properly balanced or the surface being buffed is uneven.

- Gouging: This is a deep scratch that can be caused by a chipped or damaged wheel.

- Burning: This is a discoloration of the metal surface that can be caused by excessive heat from the wheel.

- Loading: This is a buildup of material on the wheel that can reduce its effectiveness.

6. How do you troubleshoot and correct common problems that can occur when wheel buffing?

- Chattering: This can be corrected by balancing the wheel or by using a softer wheel.

- Gouging: This can be corrected by using a new or undamaged wheel.

- Burning: This can be corrected by reducing the speed of the wheel or by using a less abrasive wheel.

- Loading: This can be corrected by cleaning the wheel with a wire brush or by using a dressing stick.

7. What are the different types of finishes that can be achieved with wheel buffing?

- Matte finish: This is a dull, non-reflective finish that is created by using a low speed and a coarse abrasive wheel.

- Satin finish: This is a semi-glossy finish that is created by using a medium speed and a medium abrasive wheel.

- Glossy finish: This is a high-gloss finish that is created by using a high speed and a fine abrasive wheel.

8. How do you choose the right wheel buffing compound for a particular job?

The type of wheel buffing compound used will depend on the material being buffed and the desired finish. The following are some of the most common types of wheel buffing compounds:

- Aluminum oxide: This is a general-purpose compound that can be used on a variety of materials, including aluminum, steel, and stainless steel.

- Chromium oxide: This is a harder compound that is used for polishing hard materials, such as steel and cast iron.

- Tripoli: This is a softer compound that is used for polishing soft materials, such as aluminum and brass.

9. How do you maintain a wheel buffing machine?

Regular maintenance is essential to keep a wheel buffing machine running smoothly and efficiently. The following are some of the most important maintenance tasks:

- Inspect the machine regularly for any signs of damage or wear.

- Clean the machine regularly to remove any dust or debris.

- Lubricate the machine regularly to keep it running smoothly.

- Calibrate the machine regularly to ensure that it is operating at the correct speed.

10. What are some of the latest trends in wheel buffing technology?

- Automated wheel buffing machines: These machines can be programmed to perform a variety of buffing operations, including cutting, polishing, and finishing.

- Laser wheel buffing: This technology uses a laser to remove surface imperfections from metal surfaces.

- Nanotechnology wheel buffing: This technology uses nanoparticles to create a more uniform and durable finish on metal surfaces.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Buffer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Buffer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Buffers are responsible for maintaining the cleanliness and appearance of aircraft wheels and tires. They play a crucial role in ensuring the safety and efficiency of aircraft operations.

1. Wheel Cleaning and Inspection

The primary responsibility of a Wheel Buffer is to clean and inspect aircraft wheels and tires.

- Use specialized equipment and cleaning solutions to remove dirt, debris, and contaminants.

- Inspect wheels and tires for any signs of damage, wear, or corrosion.

- Report any issues or potential hazards to maintenance personnel.

2. Tire Pressure Maintenance

Wheel Buffers are responsible for maintaining proper tire pressure in accordance with manufacturer’s specifications.

- Check tire pressure using a tire gauge.

- Adjust tire pressure as necessary using an inflation device.

3. Wheel and Tire Maintenance

In addition to cleaning and inspecting wheels and tires, Wheel Buffers also perform basic maintenance tasks.

- Apply protective coatings to wheels and tires to prevent corrosion.

- Replace worn or damaged valve caps.

4. Safety and Compliance

Wheel Buffers are required to adhere to strict safety and compliance protocols.

- Wear appropriate safety gear including gloves, apron, and safety glasses.

- Follow all established safety procedures and guidelines.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a Wheel Buffer interview requires a combination of research, practice, and self-reflection.

1. Research the Company and Role

Take the time to learn about the airline or company you’re applying to and the specific job responsibilities of a Wheel Buffer in their organization.

- Visit the company’s website to gather information.

- Read industry news and articles to stay updated on best practices.

2. Practice Common Interview Questions

Anticipate commonly asked interview questions and prepare your responses accordingly. Here are some examples:

- Tell me about your experience in cleaning and inspecting aircraft wheels and tires.

- How do you ensure tire pressure is maintained at optimal levels?

- Describe your knowledge of wheel and tire maintenance procedures.

3. Highlight Relevant Skills and Experience

Emphasize your skills and experience that are most relevant to the job requirements. For instance:

- Attention to detail and a keen eye for spotting potential issues.

- Experience using specialized cleaning equipment and solutions.

- Understanding of tire pressure maintenance and troubleshooting.

4. Prepare Questions for the Interviewer

Asking thoughtful questions at the end of the interview demonstrates your interest and engagement.

- Inquire about the company’s safety protocols and training opportunities.

- Ask about the team structure and advancement possibilities.

- Seek clarification on any aspects of the job responsibilities.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Buffer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!