Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wheel Grinder position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

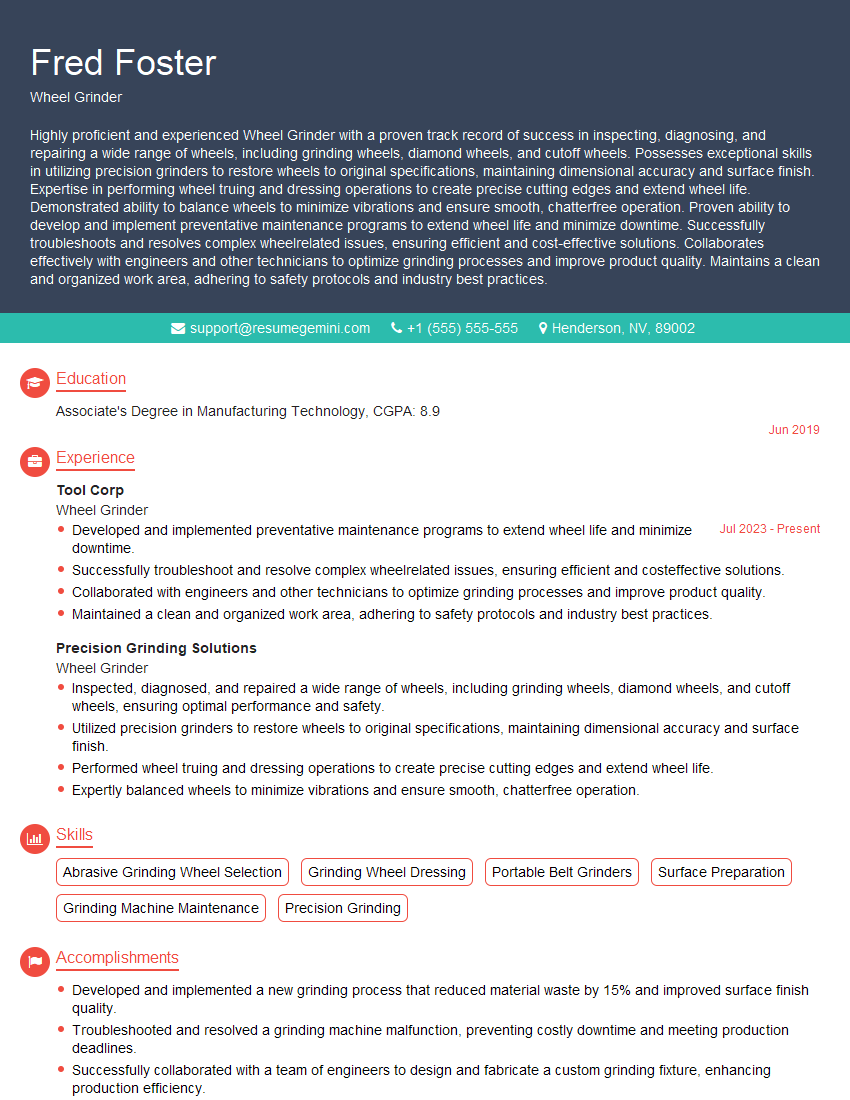

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Grinder

1. Explain the process of grinding a wheel?

The process of grinding a wheel involves several steps:

- Mounting the wheel: The wheel is mounted on a grinding machine using appropriate fixtures.

- Dressing the wheel: The grinding wheel is dressed using a dressing tool to remove any glazed or uneven surfaces.

- Selecting the grinding parameters: The grinding parameters, such as wheel speed, feed rate, and depth of cut, are selected based on the material and desired finish.

- Grinding the wheel: The wheel is brought into contact with the workpiece and moved with specified parameters to remove material and achieve the desired shape and finish.

- Checking the results: The ground wheel is inspected to ensure it meets the required specifications, such as dimensional accuracy and surface finish.

2. What are the different types of grinding wheels?

Abrasives

- Aluminum oxide: General-purpose abrasive, suitable for a wide range of materials.

- Silicon carbide: Used for grinding harder materials, such as ceramics and glass.

Bonds

- Vitrified bond: Strong and durable, suitable for heavy-duty grinding.

- Resinoid bond: Flexible, allowing for faster grinding but less durable.

- Rubber bond: Used for grinding delicate materials.

Shapes

- Cylinder wheels: Used for cylindrical grinding.

- Cup wheels: Used for surface grinding and shaping.

- Dish wheels: Used for grinding internal surfaces.

3. How do you select the right grinding wheel for a specific application?

Selecting the right grinding wheel involves considering several factors:

- Material of the workpiece: The abrasive should be compatible with the workpiece material.

- Desired surface finish: Finer abrasives produce smoother finishes.

- Removal rate: Coarser abrasives remove material faster.

- Grinding machine capabilities: The wheel size and shape must fit the machine.

- Cost and availability: Consider the price and availability of the wheel.

4. What are the safety precautions that should be taken when grinding?

- Wear appropriate PPE, including eye protection, gloves, and respiratory protection.

- Ensure the grinding machine is properly guarded.

- Inspect the grinding wheel before use and replace any damaged or worn wheels.

- Mount the wheel securely and balance it properly.

- Use the correct grinding parameters and avoid excessive forces.

5. How do you troubleshoot common grinding problems?

- Chattering: Adjust the feed rate or dressing the wheel.

- Burning: Reduce the depth of cut or increase the coolant flow.

- Glazing: Dress the wheel to remove glazed surfaces.

- Vibration: Check the wheel balance or machine alignment.

- Wheel breakage: Replace the wheel immediately and investigate the cause of breakage.

6. What is the difference between surface grinding and cylindrical grinding?

- Surface grinding: Used to create a flat surface on a workpiece.

- Cylindrical grinding: Used to create a cylindrical shape on a workpiece.

7. How do you calculate the surface roughness of a ground surface?

Surface roughness can be calculated using various methods, including:

- Ra (Roughness Average): The average height of the peaks and valleys within a specified sampling length.

- Rz (Ten-Point Height): The average height of the five highest peaks and five deepest valleys within a specified sampling length.

8. What are the advantages of using a CNC grinding machine?

- Increased precision and accuracy

- Reduced cycle times

- Improved surface finish

- Automated operation

9. What is the role of coolant in grinding?

Coolant in grinding serves several purposes:

- Cooling: Remove heat generated during grinding, preventing thermal damage to the workpiece and wheel.

- Lubrication: Reduce friction between the wheel and workpiece, improving grinding efficiency.

- Chip removal: Flush away grinding chips, preventing clogging and improving surface finish.

10. How do you maintain a grinding machine?

Maintaining a grinding machine involves regular tasks, including:

- Cleaning and lubricating the machine

- Replacing worn parts, such as bearings and belts

- Checking and adjusting the alignment of the machine components

- Calibrating the machine to ensure accuracy

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Grinder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Grinder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Grinders are responsible for grinding and finishing metal surfaces to meet specific dimensions and tolerances. They use a variety of grinding machines and tools to remove excess material and create smooth, polished surfaces. Key job responsibilities include:

1. Grinding and finishing metal surfaces

Wheel Grinders use a variety of grinding machines to remove excess material from metal surfaces. They may also use abrasive belts, stones, or other tools to create a smooth, polished finish.

2. Inspecting and measuring surfaces

Wheel Grinders are responsible for ensuring that the surfaces they grind meet specific dimensions and tolerances. They use a variety of measuring tools to inspect surfaces and ensure that they are within the required specifications.

3. Maintaining and repairing grinding machines

Wheel Grinders are responsible for maintaining and repairing the grinding machines they use. This includes regular cleaning, lubrication, and calibration. They may also perform minor repairs, such as replacing belts or stones.

4. Following safety procedures

Wheel Grinders work with hazardous materials and equipment. They are responsible for following all safety procedures to protect themselves and others. This includes wearing appropriate personal protective equipment (PPE), such as gloves, goggles, and a dust mask.

Interview Tips

To ace your interview for a Wheel Grinder position, it is important to be prepared and to have a clear understanding of the job requirements. Here are a few tips to help you succeed:

1. Research the company and the position

Before your interview, take some time to research the company and the specific position you are applying for. This will help you understand the company’s culture, values, and what they are looking for in a Wheel Grinder.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?” It is helpful to practice your answers to these questions in advance so that you can deliver them confidently and clearly.

3. Highlight your skills and experience

When answering interview questions, be sure to highlight the skills and experience that are relevant to the Wheel Grinder position. For example, you might discuss your experience using grinding machines, your ability to inspect and measure surfaces, or your commitment to safety.

4. Be prepared to talk about your safety record

Wheel Grinders work with hazardous materials and equipment, so it is important to have a strong safety record. In your interview, be prepared to talk about your safety record and how you have followed safety procedures in the past.

Next Step:

Now that you’re armed with the knowledge of Wheel Grinder interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Wheel Grinder positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini