Are you gearing up for a career in Wheel Lacer and Truer? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wheel Lacer and Truer and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

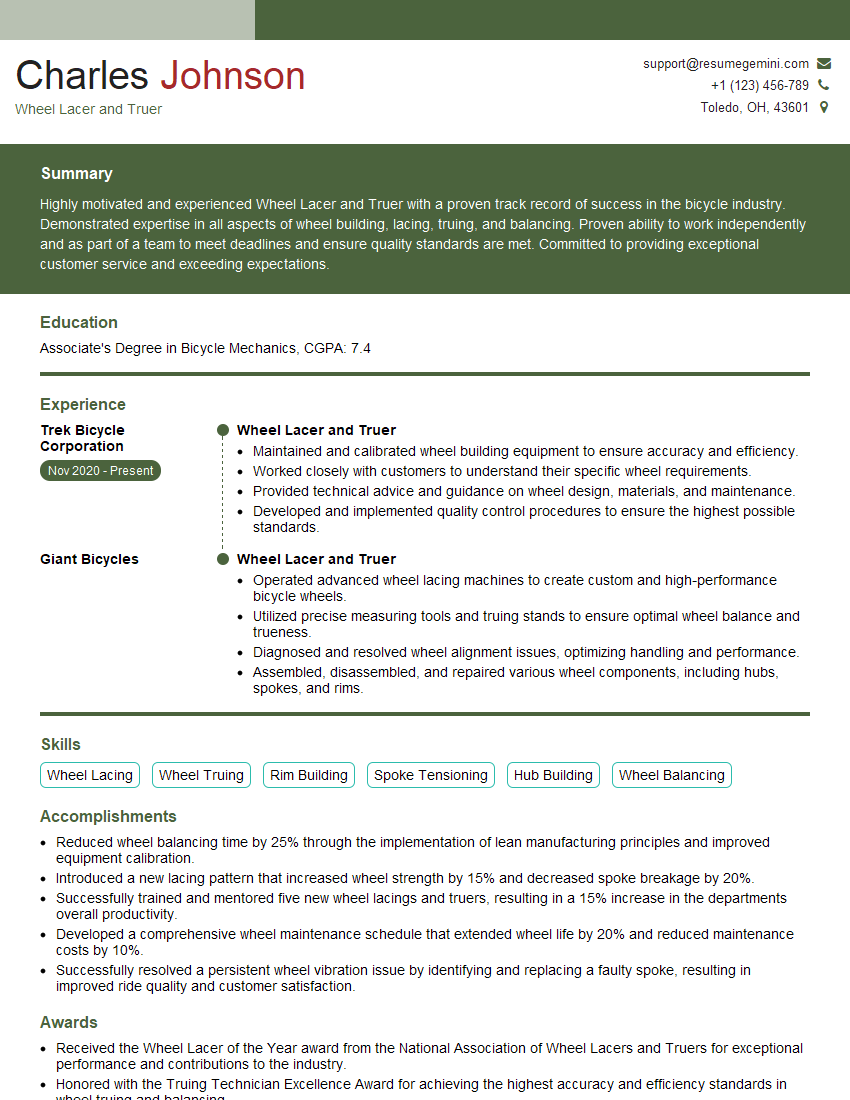

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Lacer and Truer

1. What are the major components of a wheel lacer and truer, and what is their function?

The major components of a wheel lacer and truer include:

- Frame: The frame provides a stable base for the machine and supports the other components.

- Lacing head: The lacing head holds the wheel and rotates it while the spokes are being laced.

- Spokes: The spokes connect the hub to the rim and provide support for the wheel.

- Nipples: The nipples are used to adjust the tension of the spokes.

- Truing stand: The truing stand is used to align the wheel so that it runs true.

2. How do you determine the correct spoke length for a wheel?

Spoke Calculator

- Use a spoke calculator to calculate the correct spoke length based on the hub, rim, and lacing pattern.

- The spoke calculator takes into account factors such as the hub flange diameter, rim diameter, and number of spokes.

Checking Spoke Length

- Measure the existing spokes on the wheel (if available) to determine the correct length.

- Alternatively, you can use a spoke length gauge to measure the distance between the hub flange and the rim flange.

3. What are the different lacing patterns used for bicycle wheels?

The most common lacing patterns used for bicycle wheels include:

- Radial lacing: The spokes are laced directly from the hub to the rim in a straight line.

- Cross lacing: The spokes are crossed over each other as they go from the hub to the rim.

- Tangential lacing: The spokes are laced tangentially to the rim, meaning they touch the rim at a point.

4. How do you tension spokes correctly?

To tension spokes correctly, follow these steps:

- Start by bringing all the spokes to a base tension using a spoke tension meter.

- Next, increase the tension of the spokes gradually, alternating between the spokes on each side of the wheel.

- Continue tensioning the spokes until the wheel is true and has the desired tension.

- Use a spoke tension meter to ensure that all the spokes are at the same tension.

5. What are the common problems that can occur with wheels, and how do you troubleshoot them?

Common problems that can occur with wheels include:

- Buckled wheel: A buckled wheel is a wheel that is out of true. This can be caused by a number of factors, such as a loose spoke, a bent rim, or a damaged hub.

- Loose spokes: Loose spokes can cause the wheel to be unstable and can lead to a buckled wheel.

- Bent rim: A bent rim can cause the wheel to be out of true and can make it difficult to ride.

- Damaged hub: A damaged hub can cause the wheel to be unstable and can make it difficult to ride.

6. How do you maintain a wheel lacer and truer?

To maintain a wheel lacer and truer, follow these steps:

- Keep the machine clean and free of debris.

- Lubricate the moving parts regularly.

- Inspect the machine regularly for any signs of damage or wear.

- Calibrate the machine regularly to ensure that it is operating correctly.

7. What are the safety precautions that should be taken when using a wheel lacer and truer?

When using a wheel lacer and truer, it is important to take the following safety precautions:

- Wear eye protection.

- Wear gloves.

- Do not operate the machine if you are tired or under the influence of alcohol or drugs.

- Keep children and pets away from the machine.

8. What are the different types of spokes that can be used on a bicycle wheel?

The different types of spokes that can be used on a bicycle wheel include:

- Steel spokes: Steel spokes are the most common type of spoke and are made from a variety of steel alloys.

- Stainless steel spokes: Stainless steel spokes are more corrosion-resistant than steel spokes and are often used on high-end bicycles.

- Titanium spokes: Titanium spokes are the lightest and strongest type of spoke, but they are also the most expensive.

- Aluminum spokes: Aluminum spokes are a good compromise between weight and strength, and they are often used on mid-range bicycles.

9. What are the different types of rims that can be used on a bicycle wheel?

The different types of rims that can be used on a bicycle wheel include:

- Aluminum rims: Aluminum rims are the most common type of rim and are made from a variety of aluminum alloys.

- Carbon fiber rims: Carbon fiber rims are lighter and stronger than aluminum rims, but they are also more expensive.

- Steel rims: Steel rims are the heaviest and least expensive type of rim, but they are also the most durable.

10. What are the different types of hubs that can be used on a bicycle wheel?

The different types of hubs that can be used on a bicycle wheel include:

- Freehub hubs: Freehub hubs allow the wheel to freewheel, which means that the rider can coast without pedaling.

- Fixed-gear hubs: Fixed-gear hubs do not allow the wheel to freewheel, which means that the rider must pedal constantly in order to move forward.

- Internally geared hubs: Internally geared hubs have a planetary gear system that is enclosed within the hub, which provides a wide range of gears without the need for a derailleur.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Lacer and Truer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Lacer and Truer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Lacers and Truers play a critical role in maintaining and repairing wheels for various vehicles, ensuring their proper alignment and balance. Their key responsibilities include:

1. Lacing and Truing of Wheels

Inspecting wheels for damage and defects, identifying any issues with spokes, rims, or hubs.

- Using specialized tools to lace wheels, ensuring proper tension and alignment of spokes.

- Truing wheels using specialized machines to restore their circular shape and ensure they run smoothly.

2. Balancing Wheels

Identifying and correcting imbalances in wheels using balancing equipment.

- Adding weights to wheels to ensure they rotate evenly and reduce vibration.

- Using laser alignment systems to ensure accurate wheel positioning and alignment.

3. Wheel Maintenance and Repair

Performing routine maintenance on wheels, including cleaning, lubrication, and spoke tension adjustments.

- Repairing damaged wheels by replacing or repairing spokes, hubs, or rims.

- Inspecting wheels for cracks, bends, and other defects, and recommending repairs or replacements as necessary.

4. Customer Service and Consultation

Providing excellent customer service by addressing customer inquiries and concerns related to wheel maintenance and repair.

- Advising customers on the best wheel maintenance practices and recommending appropriate repairs or upgrades.

- Building strong relationships with customers by providing professional and timely service.

Interview Tips

To ace the interview for a Wheel Lacer and Truer position, candidates should:

1. Prepare for Common Interview Questions

Research common interview questions specific to the industry and prepare well-rehearsed answers.

- Practice answering questions on your experience with wheel lacing, truing, and balancing.

- Be prepared to discuss your knowledge of wheel maintenance and repair techniques.

2. Showcase Your Technical Skills and Experience

Highlight your technical skills and experience in wheel lacing, truing, and balancing.

- Provide specific examples of projects where you demonstrated your expertise and the results achieved.

- Quantify your accomplishments whenever possible, using numbers and metrics to showcase your impact.

3. Demonstrate Your Problem-Solving Ability

Employers value candidates who can solve problems and make sound decisions.

- Share examples of how you have diagnosed and resolved wheel-related issues in the past.

- Explain your approach to problem-solving and how you prioritize tasks and manage your time.

4. Emphasize Your Customer Service Skills

Wheel Lacers and Truers often interact with customers, so it’s crucial to demonstrate your customer service skills.

- Provide examples of how you have handled difficult customers and resolved their concerns.

- Emphasize your ability to communicate effectively and build rapport with customers.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Lacer and Truer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!