Ever felt underprepared for that crucial job interview? Or perhaps you’ve landed the interview but struggled to articulate your skills and experiences effectively? Fear not! We’ve got you covered. In this blog post, we’re diving deep into the Wheel Molder interview questions that you’re most likely to encounter. But that’s not all. We’ll also provide expert insights into the key responsibilities of a Wheel Molder so you can tailor your answers to impress potential employers.

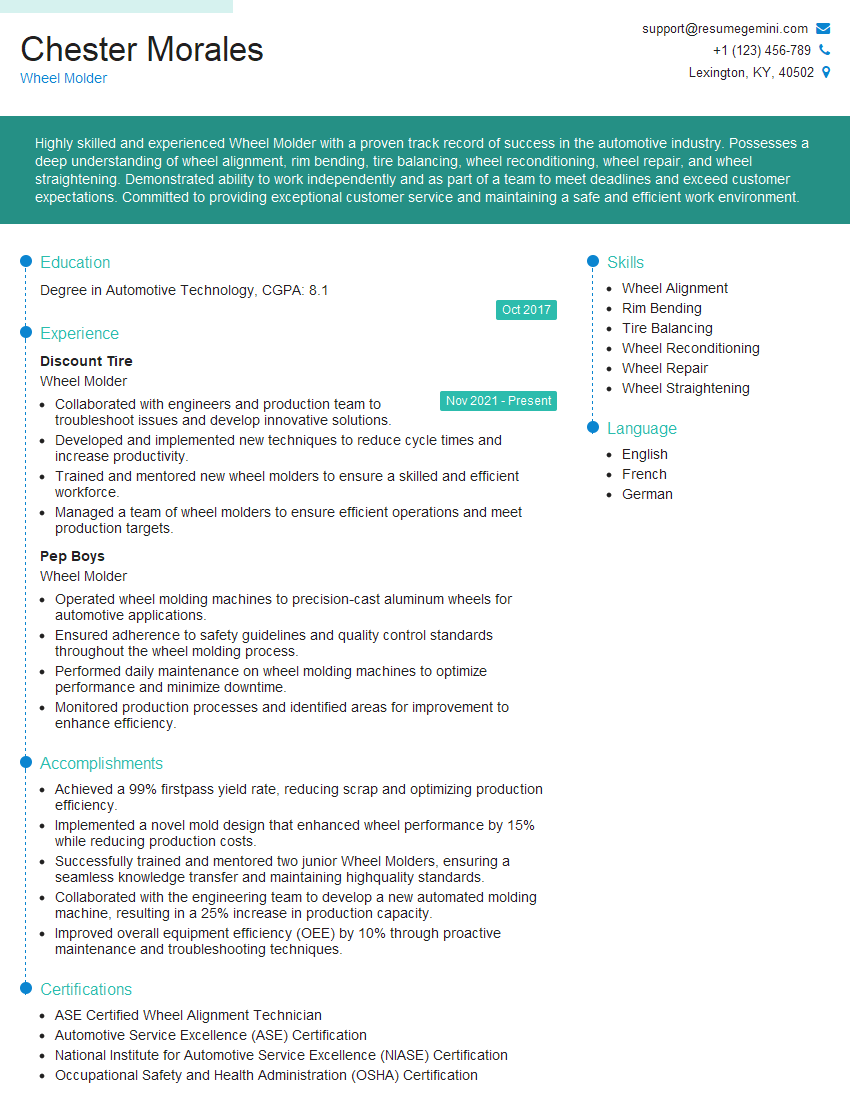

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Molder

1. Describe the key steps involved in wheel molding?

The key steps involved in wheel molding are:

- Pattern making: Creating a pattern of the desired wheel using wood, metal, or other materials.

- Mold making: Using the pattern to create a mold in sand, plaster, or other materials.

- Core making: Creating a core to shape the interior of the wheel.

- Molding: Pouring molten metal into the mold and around the core.

- Cooling: Allowing the metal to cool and solidify.

- Casting: Removing the wheel from the mold and core.

- Finishing: Trimming, grinding, and machining the wheel to the desired specifications.

2. What are the different types of molding processes used in wheel molding?

The different types of molding processes used in wheel molding include:

- Sand casting: Using sand as the mold material.

- Permanent mold casting: Using a reusable metal mold.

- Centrifugal casting: Pouring molten metal into a rotating mold.

- Die casting: Injecting molten metal into a steel die.

- Investment casting: Using a wax pattern and ceramic mold.

3. What are the critical quality control parameters in wheel molding?

The critical quality control parameters in wheel molding include:

- Dimensional accuracy: Ensuring that the wheel meets the specified dimensions.

- Surface finish: Inspecting the wheel for any defects or imperfections.

- Structural integrity: Testing the wheel for strength and durability.

- Metallurgical properties: Analyzing the wheel’s chemical composition and microstructure.

- Performance testing: Evaluating the wheel’s performance under various operating conditions.

4. What are the common defects that can occur in wheel molding and how can they be prevented?

Common defects in wheel molding include:

Defects

- Shrinkage porosity

- Gas porosity

- Cold shuts

- Cracks

- Inclusions

Prevention

- Using proper gating and risering techniques

- Controlling the pouring temperature

- Ensuring adequate mold venting

- Proper mold preparation

- Selecting the right mold materials

5. What are the safety precautions that must be followed in wheel molding?

The safety precautions that must be followed in wheel molding include:

- Wearing appropriate protective gear, including gloves, safety glasses, and a respirator.

- Handling molten metal with extreme care.

- Ensuring that the work area is well-ventilated.

- Using proper lifting techniques to avoid injuries.

- Following established safety procedures and protocols.

6. How do you ensure that the wheels produced meet the customer’s specifications?

To ensure that the wheels produced meet the customer’s specifications, I:

- Review the customer’s specifications thoroughly.

- Select the appropriate molding process and materials.

- Implement quality control measures throughout the molding process.

- Inspect the wheels carefully before delivery.

- Obtain feedback from customers and make adjustments as needed.

7. How do you stay updated with the latest advancements in wheel molding technology?

I stay updated with the latest advancements in wheel molding technology by:

- Reading industry publications and attending conferences.

- Participating in training and development programs.

- Networking with other professionals in the field.

- Researching and experimenting with new techniques.

8. Describe a challenging project you worked on in wheel molding and how you overcame the challenges.

One challenging project I worked on was developing a new type of wheel for a high-performance vehicle. The wheel needed to be lightweight, strong, and durable. I overcame the challenges by:

- Using a combination of different molding techniques.

- Experimenting with different materials and alloys.

- Consulting with experts in the field.

- Implementing rigorous quality control measures.

9. What are your strengths and weaknesses as a Wheel Molder?

Strengths

- Expertise in various wheel molding processes.

- Strong understanding of metallurgy and material properties.

- Excellent problem-solving and critical thinking skills.

- High attention to detail and commitment to quality.

Weaknesses

- Limited experience with certain specialized molding techniques.

- Working long hours can be physically demanding.

10. Why are you interested in working as a Wheel Molder in our company?

I am interested in working as a Wheel Molder in your company because:

- Your company has a reputation for excellence in the industry.

- You offer a competitive salary and benefits package.

- The opportunity to work on challenging and innovative projects.

- The chance to contribute to the success of your company.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Molder.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Molder‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Molders create and maintain molds used in the production of wheels for vehicles.

1. Mold Creation

Design and construct molds based on specifications, using various mold-making techniques

- Assemble and secure mold components, ensuring precision and accuracy

- Inspect molds for defects and make necessary adjustments

2. Mold Maintenance

Maintain and repair wheel molds to ensure optimal performance

- Identify and resolve mold issues, such as cracks, leaks, and corrosion

- Perform regular maintenance tasks to extend mold life

3. Production Support

Provide technical support to production teams during the wheel casting process

- Assist with troubleshooting and resolving casting problems

- Monitor production progress and make adjustments as needed

4. Quality Control

Inspect wheels produced from molds to ensure they meet quality standards

- Identify and correct defects in wheels

- Maintain quality records and report on mold performance

Interview Tips

Preparing for an interview as a Wheel Molder can increase your chances of success. Here are some tips to help you ace the interview:

1. Research the Company and Position

Gain insights into the company’s culture, values, and the specific requirements of the Wheel Molder position.

- Visit the company’s website and social media pages

- Read industry publications and articles

2. Showcase Your Molding Expertise

Highlight your knowledge and experience in mold design, fabrication, and maintenance.

- Provide specific examples of successful mold projects you’ve worked on

- Discuss your understanding of different mold-making techniques

3. Emphasize Your Problem-Solving Skills

Wheel Molders often encounter issues during the production process.

- Share examples of how you have identified and resolved mold problems

- Explain your approach to troubleshooting and root cause analysis

4. Prepare for Technical Questions

Be prepared to answer questions about mold design, materials, and casting processes.

- Review common mold-making techniques and materials

- Research the different types of casting processes used in wheel production

5. Practice Your Communication Skills

Clear and effective communication is essential.

- Practice articulating your technical knowledge and experience

- Be prepared to answer questions about your team-working and problem-solving abilities

6. Dress Professionally and Arrive on Time

Dressing appropriately and arriving on time for your interview conveys professionalism and respect for the employer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Molder interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!