Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wheel Polisher position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

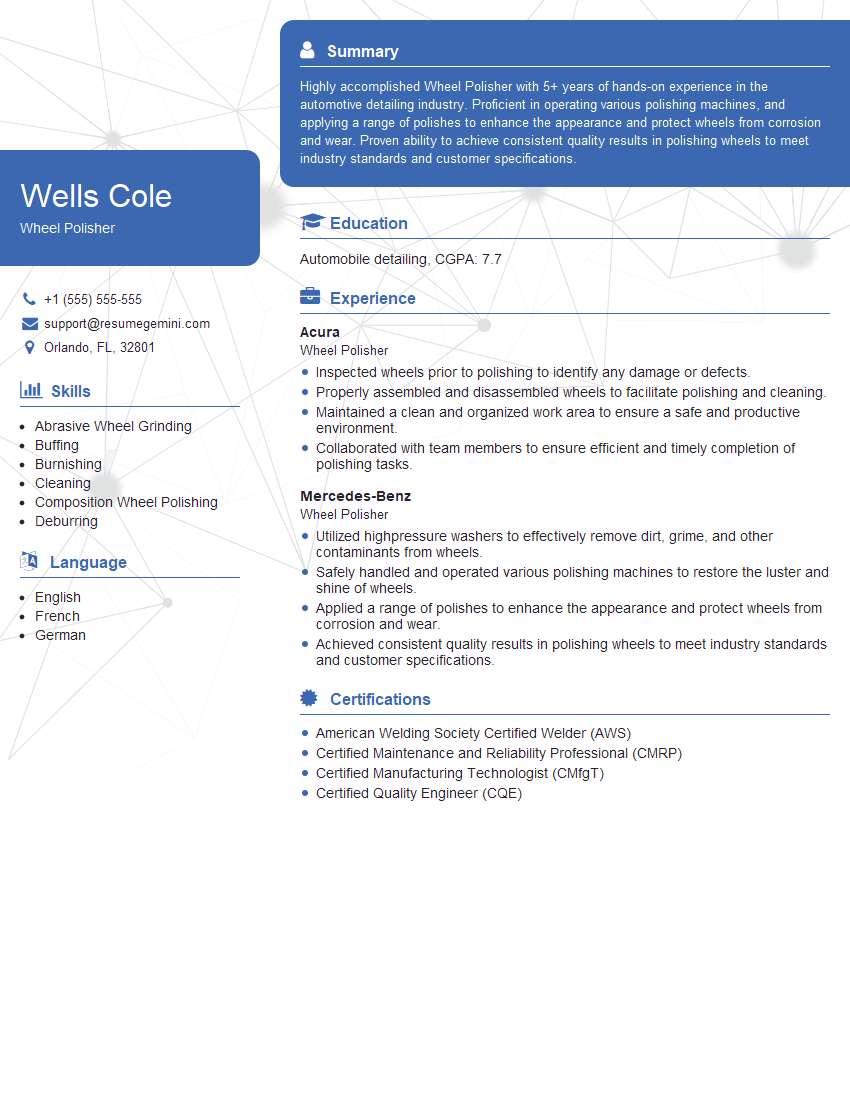

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Polisher

1. How do you prepare a vehicle’s surface for wheel polishing?

To prepare a vehicle’s surface for wheel polishing, I follow these steps:

- Clean the wheels and tires thoroughly using a wheel cleaner.

- Decontaminate the wheels using a clay bar to remove any impurities or contaminants.

- Mask off any areas that should not be polished, such as brake pads.

- Protect the surrounding areas with a protective cover.

2. What types of polishing compounds and pads do you use for different wheel finishes?

Polishing Compounds:

Heavy-cut compound

- Removes deep scratches and imperfections.

- Used on heavily oxidized or damaged wheels.

Medium-cut compound

- Removes moderate scratches and imperfections.

- Used to refine the surface after heavy-cut compound.

Light-cut compound

- Removes light scratches and imperfections.

- Used to finish and restore the wheel’s shine.

Polishing Pads:

- Wool pad: Aggressive cut, used with heavy-cut compound.

- Foam pad: Medium cut to light cut, versatile for various compounds.

- Microfiber pad: Light cut to finishing, produces a fine finish.

3. How do you identify and treat different types of wheel damage?

I can identify and treat various types of wheel damage, including:

- Scratches: Use a suitable polishing compound and pad to remove them.

- Curb rash: Requires sanding to smooth out the area, followed by polishing.

- Corrosion: Remove corrosion with a chemical or abrasive cleaner, then polish to restore finish.

- Oxidation: Use a heavy-cut compound to remove the oxidized layer, then follow with finer compounds to restore the shine.

4. How do you determine the correct polishing technique for different wheel materials?

The polishing technique depends on the wheel material:

- Painted wheels: Use light to medium-cut compounds and avoid excessive heat.

- Chrome wheels: Use non-abrasive compounds to maintain the chrome finish.

- Aluminum wheels: Use medium to heavy-cut compounds and a firm pad to remove imperfections.

- Mag wheels: Avoid aggressive polishing techniques to prevent damage.

5. How do you ensure the quality of your wheel polishing services?

I ensure quality by:

- Using high-quality materials and equipment.

- Following proper polishing techniques.

- Inspecting the wheels thoroughly before and after polishing.

- Seeking customer feedback to improve my services.

6. What safety precautions do you take while wheel polishing?

For safety, I:

- Wear appropriate personal protective equipment, including gloves, safety glasses, and a respirator.

- Operate the polishing equipment in a well-ventilated area.

- Handle chemicals carefully and dispose of them properly.

- Avoid overheating the wheels during polishing.

7. How do you stay up-to-date with the latest wheel polishing techniques and trends?

I stay current with industry best practices by:

- Attending workshops and conferences.

- Reading industry publications.

- Connecting with other professionals in the field.

- Experimenting with new techniques and products.

8. What is the most challenging aspect of wheel polishing?

The most challenging aspect is restoring severely damaged wheels while ensuring the best possible finish.

- Deep curb rash and corrosion require extensive repair.

- Matching the original finish and texture can be difficult.

- Balancing speed and precision to achieve both efficiency and quality.

9. How do you deal with customers who are not satisfied with your work?

When a customer is not satisfied, I:

- Listen attentively to their concerns.

- Inspect the wheels to identify any issues.

- Offer a solution, such as re-polishing or a refund.

- Maintain a positive and professional attitude.

10. Why are you the best candidate for this wheel polishing position?

I am the best candidate for this position because:

- I have extensive experience in wheel polishing and detailing.

- I am proficient in using various polishing techniques and materials.

- I am committed to providing high-quality results and customer satisfaction.

- I am a hard worker and I am always willing to go the extra mile.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Polisher.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Polisher‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Polishers are responsible for polishing and refinishing wheels to restore their original appearance. They typically work in a manufacturing or automotive repair setting, using specialized equipment to remove scratches, oxidation, and other imperfections from wheels. Some of the key job responsibilities include:

1. Wheel preparation

Prior to polishing, they must prepare the wheels by removing any dirt, grease, or other contaminants. This may involve using a variety of cleaning agents and tools, such as brushes, rags, and degreasers.

2. Polishing and refinishing

Once the wheels are clean, they can begin the polishing process. This typically involves using a polishing wheel or machine, along with a polishing compound, to remove scratches and other imperfections from the surface of the wheel. The type of polishing compound used will depend on the material of the wheel and the desired finish.

3. Buffing

After polishing, the wheels are buffed to remove any remaining polishing compound and to create a smooth, shiny finish. This process may involve using a buffing wheel or machine, along with a buffing compound.

4. Other duties

In addition to polishing and refinishing wheels, Wheel Polishers may also be responsible for performing other tasks, such as:

- Inspecting wheels for damage or wear

- Repairing minor damage to wheels

- Maintaining and cleaning polishing equipment

Interview Tips

To increase your chances of success in the interview, consider the following tips:

1. Research the company and the position

Before the interview, take some time to research the company you are applying to and the position you are interested in. This will help you to understand the company’s culture, values, and goals, and to tailor your answers to the specific requirements of the position.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” or “Why are you interested in this position?”. Take some time to practice your answers to these questions in advance, so that you can deliver them confidently and effectively.

3. Prepare questions to ask the interviewer

Asking thoughtful questions at the end of the interview shows that you are interested in the position and the company, and that you have done your research. Prepare a few questions in advance, such as “What are the biggest challenges facing the company right now?” or “What is the company’s culture like?”.

4. Dress professionally and arrive on time

First impressions matter, so make sure to dress professionally for your interview and arrive on time. This shows that you are respectful of the interviewer’s time and that you take the interview seriously.

5. Be yourself and be enthusiastic

The most important thing is to be yourself and to be enthusiastic about the position. The interviewer wants to get to know you and to see if you are a good fit for the company. So be genuine, be yourself, and let your passion for the position shine through.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Polisher interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!