Are you gearing up for a career in Wheel Press Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wheel Press Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

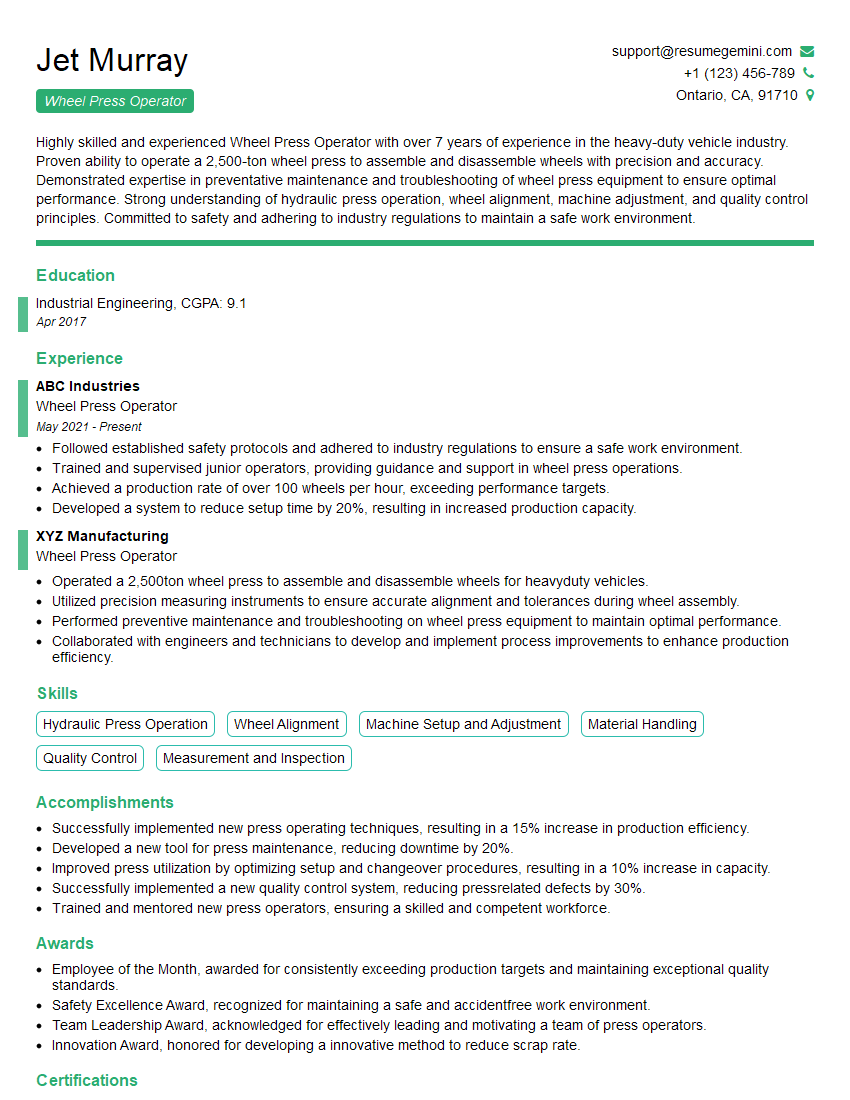

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Press Operator

1. What are the key responsibilities of a Wheel Press Operator?

As a Wheel Press Operator, my main responsibilities include:

- Operating wheel presses to assemble and disassemble components

- Ensuring that all components are securely fitted and meet quality standards

- Maintaining and calibrating wheel presses to ensure optimal performance

- Inspecting finished products to ensure they meet specifications

- Following established safety protocols and procedures

2. Can you describe the different types of wheel presses you have experience with?

Hydraulic Presses

- Use hydraulic fluid to generate high pressure for pressing and assembling

- Provide precise control over force and speed

- Commonly used for heavy-duty applications and large-scale production

Mechanical Presses

- Utilize a flywheel and gears to generate mechanical force

- Offer high speed and repetitive operation

- Suitable for smaller components and higher production rates

3. What are the safety precautions that you must observe when operating a wheel press?

To ensure a safe working environment, I adhere to the following safety precautions:

- Inspecting the wheel press and its components regularly for any defects or damage

- Wearing appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection

- Ensuring that the workpiece is securely placed and centered on the press bed

- Maintaining a safe distance from the press during operation

- Following established lockout/tagout procedures before performing maintenance or repairs

4. What are the common maintenance tasks required to keep a wheel press in optimal condition?

To ensure the proper functioning and longevity of the wheel press, I perform regular maintenance tasks, including:

- Lubricating all moving parts, such as bearings and gears

- Checking and adjusting fluid levels and pressure in hydraulic presses

- Inspecting electrical components for any loose connections or damage

- Monitoring press performance and identifying any potential issues

- Reporting any necessary repairs or replacements to the appropriate personnel

5. How do you determine the appropriate force and speed settings for different pressing operations?

To determine the optimal force and speed settings, I consider several factors:

- The material and thickness of the workpiece

- The type of pressing operation being performed (e.g., assembly, disassembly)

- The desired fit and finish of the finished product

- The recommendations provided by the manufacturer of the wheel press

6. What troubleshooting steps do you take when you encounter issues with the wheel press?

When troubleshooting issues with the wheel press, I follow a structured approach:

- Identifying the symptoms of the problem and observing its behavior

- Checking for any loose connections, leaks, or damage in the mechanical or electrical components

- Consulting the manufacturer’s manual or technical documents for guidance

- Performing diagnostic tests, such as checking fluid levels or pressure

- Seeking assistance from a qualified technician if necessary

7. Can you explain the importance of quality control in wheel press operations?

Quality control is crucial in wheel press operations to ensure that the finished products meet the desired specifications and standards.

- It helps prevent defects and ensures the reliability and safety of the products

- It minimizes rework and scrap, reducing production costs

- It maintains customer satisfaction and builds a positive reputation for the company

8. What are your methods for inspecting finished products and ensuring they meet quality standards?

To ensure the quality of finished products, I employ various inspection methods:

- Visual inspection to check for any visible defects, such as scratches, dents, or misalignment

- Dimensional inspection using measuring tools to verify the size and shape of the products

- Functional testing to ensure that the products perform as intended

- Adhering to established quality control procedures and documentation

9. How do you handle situations where the wheel press is not operating correctly or you encounter unexpected problems?

When faced with equipment issues or unexpected problems, I take the following steps:

- Stopping the operation and securing the press to prevent further damage or injury

- Identifying the cause of the problem through troubleshooting and inspection

- Taking appropriate corrective actions, such as adjusting settings, performing repairs, or replacing components

- Reporting the issue to my supervisor and seeking assistance if necessary

10. How do you prioritize your tasks and manage your time effectively when working as a Wheel Press Operator?

To prioritize my tasks and manage my time effectively, I:

- Create a daily or weekly schedule that outlines my tasks and their deadlines

- Prioritize tasks based on their urgency and importance

- Break down large tasks into smaller, manageable steps

- Delegate tasks to others when appropriate

- Use time management techniques, such as the Pomodoro Technique, to stay focused and productive

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Press Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Press Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities: Wheel Press Operator

A Wheel Press Operator is responsible for the efficient operation of wheel press machines in a manufacturing or repair setting. Here are some key job responsibilities:

1. Machine Operation

Operating wheel press machines to mount or dismount wheels from axles, shafts, or hubs

- Following established procedures and safety protocols

- Calibrating and adjusting machine settings based on job requirements

2. Material Handling

Loading and unloading heavy wheels and components onto the wheel press table

- Using proper material handling equipment and techniques

- Ensuring that all materials are handled safely and securely

3. Quality Inspection

Inspecting assembled components to ensure they meet specifications

- Using measuring tools and visual aids to verify dimensions and alignment

- Identifying and reporting any discrepancies or defects

4. Maintenance and Troubleshooting

Performing basic maintenance tasks on wheel press machines

- Lubricating and cleaning components

- Troubleshooting and resolving minor operational issues

Interview Preparation Tips: Wheel Press Operator

To ace your interview for a Wheel Press Operator position, consider the following preparation tips:

1. Research the Company and Industry

Familiarize yourself with the company’s history, products, and industry practices. This will help you understand their specific needs and how your skills align with their requirements.

2. Practice Your Technical Skills

Review the key job responsibilities and ensure you have a solid understanding of wheel press machine operation, material handling techniques, and quality inspection procedures. Practice describing your experiences in these areas using specific examples.

3. Highlight Your Safety Awareness

Emphasize your commitment to safety by discussing your knowledge of industry standards and your experience in following safety protocols. This is a critical aspect of being a Wheel Press Operator.

4. Demonstrate Your Problem-Solving Abilities

Provide examples of how you have successfully identified and resolved operational issues in the past. This will demonstrate your ability to analyze problems and find solutions, which is essential for a Wheel Press Operator.

5. Prepare Questions to Ask the Interviewer

Asking thoughtful questions at the end of the interview shows your interest in the position and the company. Consider questions about the job’s responsibilities, career advancement opportunities, or safety initiatives.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Press Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.