Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wheel Presser position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

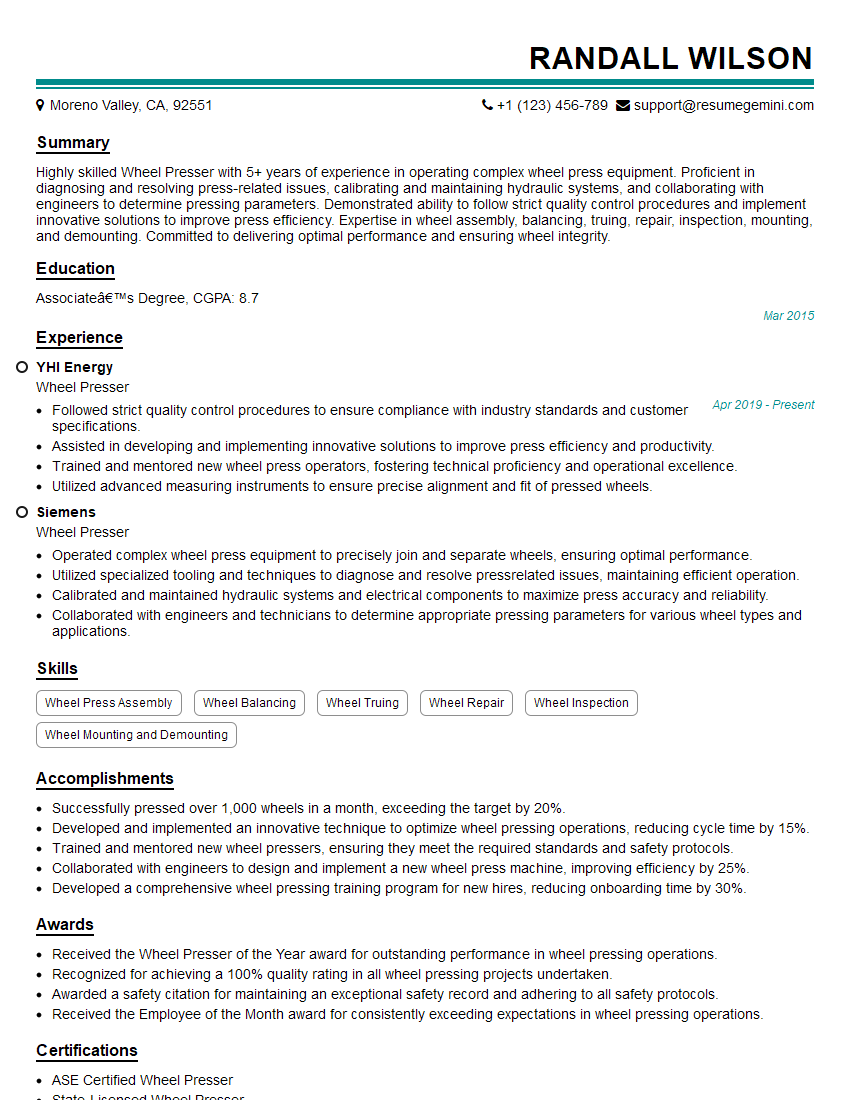

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Presser

1. Describe the key steps involved in operating a wheel press.

- Inspect the wheel and select the appropriate adapter.

- Position the wheel on the press’s turntable and center it.

- Secure the wheel using bolts or clamps.

- Select the desired pressure and cycle time.

- Initiate the press cycle and monitor the progress.

2. What safety precautions should be taken when using a wheel press?

- Ensure that the press is properly calibrated and maintained.

- Wear appropriate safety gear, including gloves, safety glasses, and hearing protection.

- Keep the work area clear of obstructions and tripping hazards.

- Do not operate the press while under the influence of drugs or alcohol.

3. How do you troubleshoot common issues that may occur during wheel pressing?

- If the wheel does not seat properly, ensure that the adapter and wheel are properly aligned.

- If the press does not cycle properly, check the hydraulic fluid level and the pressure relief valve.

- If the wheel is damaged during pressing, inspect the adapter and the press components for damage.

4. What types of wheels can be pressed using this equipment?

- Steel wheels

- Aluminum wheels

- Alloy wheels

5. What is the maximum pressure that can be applied using this wheel press?

- The maximum pressure will vary depending on the specific model of the wheel press.

6. What is the minimum and maximum size of wheels that can be pressed using this equipment?

- The minimum and maximum wheel sizes will vary depending on the specific model of the wheel press.

7. What are the key maintenance tasks that need to be performed on a wheel press?

- Regularly clean and lubricate the press components.

- Inspect the hydraulic hoses and connections for leaks.

- Check the calibration of the press.

8. What are the potential hazards associated with operating a wheel press?

- Eye injuries from flying debris

- Hand injuries from being caught in the press

- Back injuries from lifting heavy wheels

9. What are the advantages of using a wheel press over other methods of removing or installing wheels?

- Wheel presses provide a safe and controlled method of removing and installing wheels.

- They can be used on a wide variety of wheel sizes and types.

- They are relatively easy to operate and maintain.

10. What are the different types of wheel press machines available?

- Manual wheel presses

- Hydraulic wheel presses

- Air-operated wheel presses

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Presser.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Presser‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheel Pressers are responsible for assembling and disassembling wheels and tires, ensuring they meet safety and quality standards. They perform various tasks to maintain and repair wheels, tires, and associated components.

1. Wheel Assembly and Disassembly

Unpack and inspect wheels and tires for any damage.

- Assemble wheels by mounting tires onto rims, using specialized equipment.

- Disassemble wheels by separating tires from rims, using appropriate tools.

2. Wheel Maintenance and Repair

Inspect wheels and tires for wear, damage, or any irregularities.

- Repair minor wheel damage, such as dents or scratches.

- Replace worn or damaged tires, ensuring correct size and specifications.

3. Quality Control

Inspect assembled wheels and tires to ensure they meet specifications and industry standards.

- Use measuring tools to verify dimensions and clearances.

- Perform leak tests to ensure proper tire pressure and seal.

4. Safety Compliance

Follow established safety protocols to prevent accidents and injuries.

- Wear appropriate protective gear, including gloves, safety glasses, and sturdy shoes.

- Operate equipment safely, adhering to established guidelines and procedures.

Interview Tips

To ace an interview for a Wheel Presser position, it’s crucial to prepare thoroughly and highlight your skills and experience relevant to the job requirements. Here are some interview tips and preparation hacks:

1. Research the Company and Position

Familiarize yourself with the company’s background, industry, and specific role requirements. Utilize the company website, LinkedIn, and industry publications to gather information.

2. Highlight Relevant Skills and Experience

In your resume and during the interview, emphasize your proficiency in wheel assembly and disassembly, wheel maintenance and repair, and quality control procedures. Quantify your accomplishments whenever possible to demonstrate your impact and value.

3. Practice Answering Common Interview Questions

Prepare for common interview questions related to your knowledge of wheel components, safety protocols, and problem-solving abilities. Practice your answers to showcase your understanding and competence.

4. Prepare Questions for the Interviewer

Show your interest and engagement by preparing thoughtful questions for the interviewer. This demonstrates your enthusiasm and desire to learn more about the role and company.

5. Dress Professionally and Arrive on Time

First impressions matter. Dress appropriately for the interview, arrive on time, and maintain a professional demeanor throughout the process.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheel Presser interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.