Are you gearing up for an interview for a Wheel Roller position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Wheel Roller and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

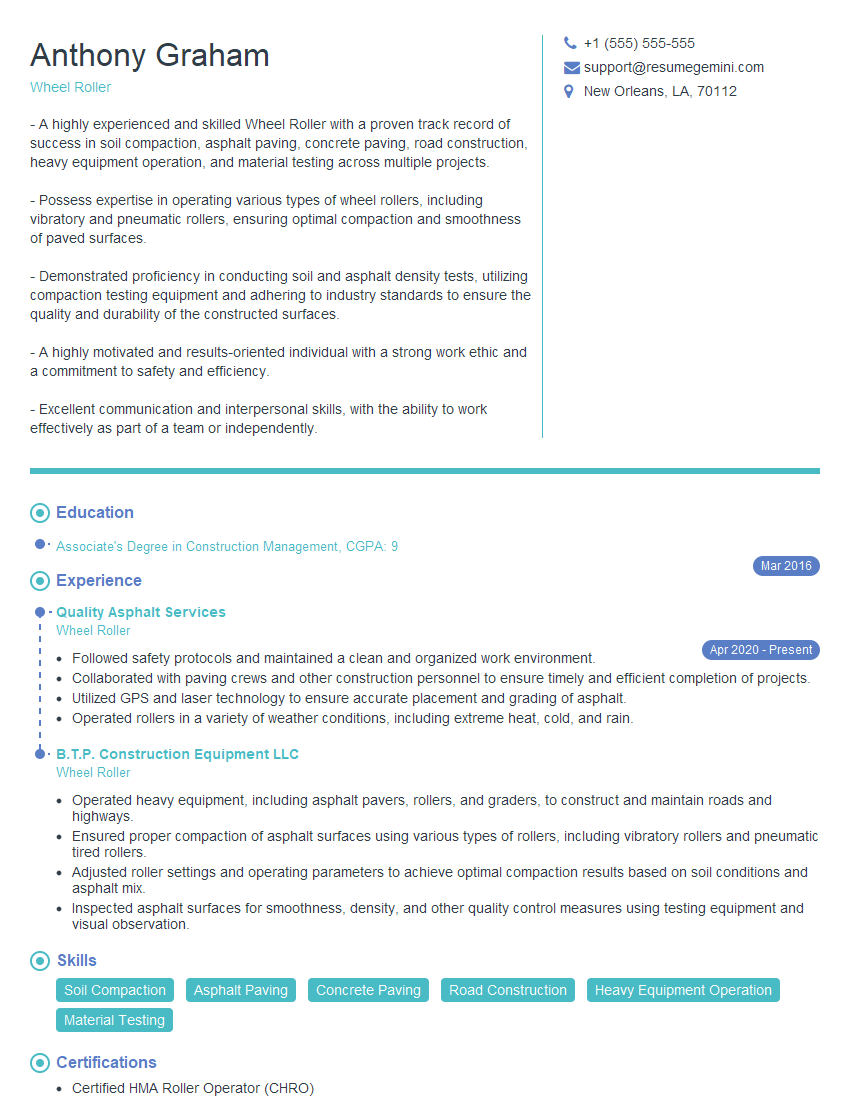

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheel Roller

1. What are the different types of wheel rollers and their applications?

Wheel rollers are classified into several types, each designed for specific applications:

- Static Wheel Rollers: These rollers are used for compacting cohesive soils and asphalt. They apply pressure through their weight and do not vibrate or oscillate.

- Vibratory Wheel Rollers: These rollers use vibration to compact soils and asphalt. The vibration helps to break down soil particles and increase density.

- Oscillatory Wheel Rollers: These rollers apply an oscillating motion to compact soils. The oscillation helps to create a smooth and level surface.

- Pneumatic Wheel Rollers: These rollers use pneumatic tires to compact soils and asphalt. They are often used on surfaces that are sensitive to vibration.

- Tamping Rollers: These rollers use a series of tamping feet to compact soils. They are often used for compacting granular soils and backfill.

2. Explain the factors that affect the compaction achieved by a wheel roller.

Weight of the Roller

- The weight of the roller determines the amount of force applied to the soil, which affects the compaction achieved.

- Heavier rollers are used for compacting deeper layers of soil or for achieving higher densities.

Vibration Frequency

- For vibratory rollers, the frequency of vibration affects the compaction achieved.

- Higher frequencies result in more intense vibration, which helps to break down soil particles and increase density.

Oscillation Amplitude

- For oscillatory rollers, the amplitude of oscillation affects the compaction achieved.

- Larger amplitudes result in more pronounced oscillation, which helps to create a smooth and level surface.

Roller Coverage

- The coverage of the roller, which is the area covered by its wheels or feet, affects the compaction achieved.

- Rollers with larger coverage can compact a wider area in a single pass.

Soil Conditions

- The compaction achieved by a wheel roller also depends on the soil conditions, such as its moisture content, particle size, and density.

- Soils with higher moisture content are more difficult to compact, while soils with smaller particle sizes require more compaction effort.

3. What are the safety precautions that need to be taken when operating a wheel roller?

- Always wear appropriate safety gear, including a hard hat, safety glasses, and gloves.

- Inspect the roller before each use to ensure it is in good working condition.

- Be aware of your surroundings and avoid operating the roller near hazards.

- Never operate the roller under the influence of drugs or alcohol.

- Follow the manufacturer’s instructions for operating the roller safely.

4. How do you determine the correct compaction pattern for a particular soil type?

- Consider the soil type and its compaction characteristics.

- Determine the desired level of compaction for the application.

- Select a roller type and operating parameters (weight, vibration frequency, etc.) that are appropriate for the soil conditions.

- Develop a compaction pattern that ensures uniform coverage and achieves the desired compaction level.

5. What are the signs of over-compaction and under-compaction in soil?

Over-compaction

- Hard, dry soil

- Cracks and fissures

- Reduced water infiltration

- Increased susceptibility to erosion

Under-compaction

- Soft, spongy soil

- Excessive settlement

- Poor load-bearing capacity

- Increased risk of failure

6. What are the maintenance procedures required for a wheel roller?

- Regularly check and clean the air filter.

- Check and adjust the tire pressure.

- Lubricate all moving parts.

- Inspect the hydraulic system for leaks.

- Follow the manufacturer’s recommended maintenance schedule.

7. How do you troubleshoot common problems that may occur with a wheel roller?

- Engine problems: Check the fuel level, air filter, and spark plugs.

- Hydraulic problems: Check the hydraulic fluid level and for any leaks.

- Electrical problems: Check the battery, wiring, and fuses.

- Compaction problems: Check the roller weight, vibration frequency, and coverage.

8. What are the latest advancements in wheel roller technology?

- GPS-based compaction control: Allows for precise compaction control and documentation.

- Automated compaction systems: Reduce operator error and improve compaction uniformity.

- Hybrid and electric rollers: Offer reduced emissions and noise levels.

- Remote monitoring systems: Allow for remote tracking and monitoring of roller performance.

9. How do you stay up-to-date with the latest industry best practices for wheel roller operation?

- Attend industry conferences and workshops.

- Read trade publications and research articles.

- Participate in online forums and discussion groups.

- Seek training from equipment manufacturers and industry experts.

10. What are your strengths and weaknesses as a wheel roller operator?

Strengths:

- Extensive experience operating wheel rollers of various types.

- Proficient in determining the correct compaction pattern for different soil conditions.

- Strong understanding of roller maintenance and troubleshooting.

- Excellent safety record and commitment to safe operating practices.

Weaknesses:

- Limited experience with GPS-based compaction control systems.

- Not familiar with all types of soil stabilization techniques.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheel Roller.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheel Roller‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wheel Roller, also known as a roller compactor, is a heavy-duty machine used in construction to compact soil, gravel, and asphalt. Key job responsibilities of a Wheel Roller include:

1. Compacting Soil and Asphalt

Use the wheel roller to compact soil and asphalt to achieve the desired density and stability. Ensure that the compaction meets specifications and industry standards.

2. Preparing Surfaces for Construction

Prepare surfaces for construction by rolling and leveling soil or asphalt. This ensures a smooth and stable base for further construction activities.

3. Repairing Roads and Pavements

Repair roads and pavements by compacting asphalt patches and overlays. Ensure that repairs meet quality standards and specifications.

4. Maintaining Equipment

Maintain the wheel roller and any associated equipment in good working condition. Perform regular inspections, cleaning, and lubrication to ensure optimal performance.

Interview Tips

To ace the interview for a Wheel Roller position, follow these tips:

1. Research the Company and Position

Thoroughly research the construction company and the specific Wheel Roller position. Familiarize yourself with their projects, values, and industry reputation. This knowledge will help you demonstrate your interest and alignment with the company’s goals.

2. Emphasize Relevant Experience

Highlight your previous experience operating wheel rollers or similar heavy machinery. Quantify your accomplishments by providing specific metrics, such as the number of square meters compacted per day or the percentage of projects completed within specified timeframes.

3. Demonstrate Technical Knowledge

Show your understanding of wheel roller operations, compaction techniques, and safety protocols. Discuss your knowledge of soil and asphalt compaction, as well as the ability to adjust roller settings based on job requirements.

4. Highlight Safety Awareness

Emphasize your commitment to safety and your knowledge of industry safety regulations. Discuss your experience in operating heavy machinery safely, including following proper procedures and using appropriate safety gear.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Wheel Roller, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Wheel Roller positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.