Feeling lost in a sea of interview questions? Landed that dream interview for Wheelwright but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Wheelwright interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

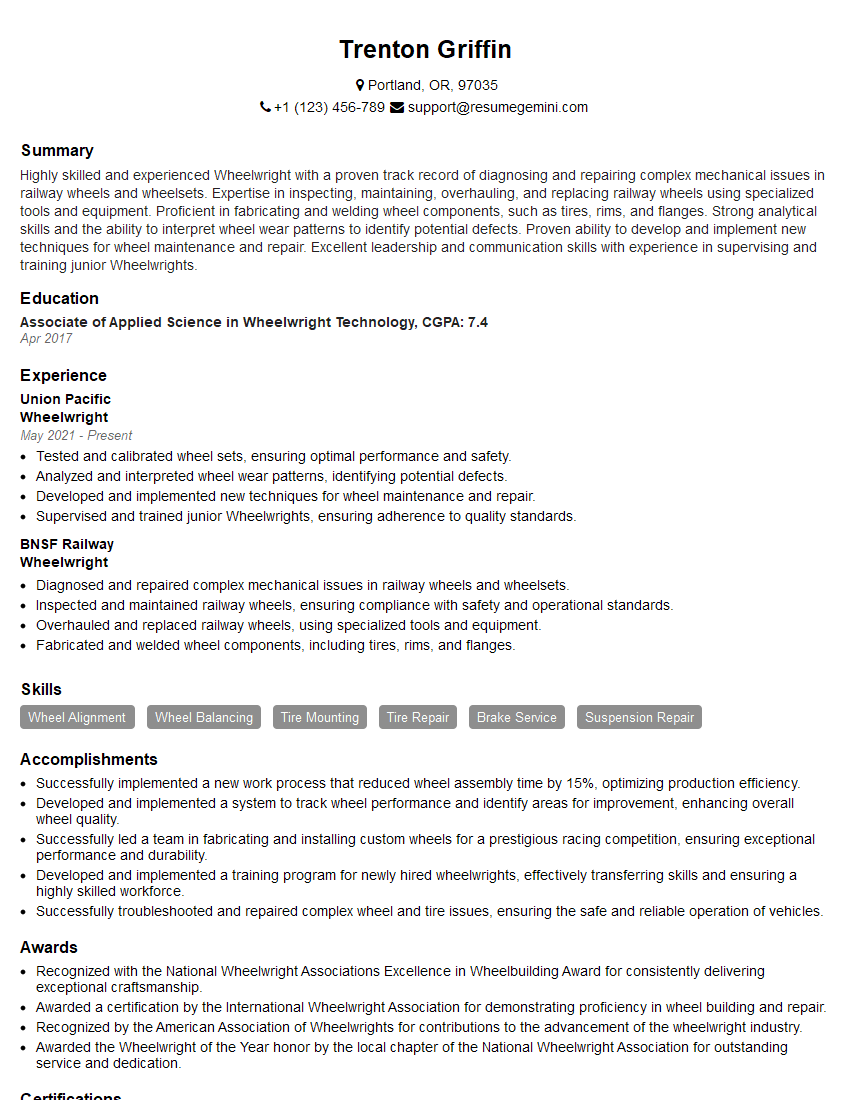

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wheelwright

1. Explain the types of wheels and their applications in the automotive industry?

There are various types of wheels used in the automotive industry, each with specific applications and performance characteristics:

- Spoked Wheels: Lightweight and durable, often used in performance and racing applications due to their ability to handle high speeds and reduce unsprung weight.

- Alloy Wheels: Made from lightweight aluminum alloys, they offer a combination of strength and weight reduction, improving handling and fuel efficiency.

- Steel Wheels: Affordable and durable, they are commonly used in budget-friendly vehicles as they can withstand wear and tear.

- Forged Wheels: Exceptionally strong and durable, they are typically used in high-performance vehicles, as they can withstand extreme forces and provide excellent handling.

- Custom Wheels: Designed to enhance the aesthetics and performance of a vehicle, they allow for personalized modifications and can improve handling and braking.

2. Describe the manufacturing process of a wheel?

Raw Material Selection

- Choose high-quality materials such as aluminum alloys or steel.

- Ensure materials meet industry standards and performance requirements.

Mold Creation

- Design and create molds based on the desired wheel specifications (size, shape, etc.).

- Precision is crucial to ensure accurate and consistent wheel production.

Casting or Forging

- Casting: Molten metal is poured into the mold and allowed to solidify.

- Forging: Metal is heated and shaped under intense pressure, resulting in a stronger and lighter wheel.

Machining and Finishing

- Machine the wheel to remove excess material and achieve precise dimensions.

- Finish the surface through processes such as painting, powder coating, or polishing.

3. What are the key factors to consider when selecting the right wheel for a vehicle?

- Vehicle Specifications: Wheel size, bolt pattern, offset, and load capacity must align with the vehicle.

- Usage and Performance: Consider the intended use of the vehicle (daily driving, racing, etc.) and the desired performance characteristics.

- Style and Aesthetics: Choose wheels that complement the vehicle’s design and personal preferences.

- Durability and Maintenance: Ensure the wheels are built to withstand the rigors of everyday use and are easy to maintain.

- Safety and Regulations: Adhere to industry standards and ensure the wheels meet safety requirements.

4. Discuss the quality control measures implemented in the wheel manufacturing process?

- Raw Material Inspection: Verify the quality and consistency of incoming materials.

- Mold Validation: Ensure molds are accurate and produce wheels that meet specifications.

- Casting or Forging Process Monitoring: Control temperature, pressure, and other parameters to guarantee consistent quality.

- Machining and Finishing Inspection: Check dimensions, surface finish, and overall workmanship.

- Wheel Testing: Conduct tests such as strength, durability, and performance evaluations to meet industry standards.

5. Explain the importance of wheel alignment and its impact on vehicle performance?

- Improved Handling and Stability: Proper alignment ensures the tires make optimal contact with the road, resulting in better handling and stability.

- Reduced Tire Wear: Correct alignment prevents uneven tire wear, prolonging tire life and saving costs.

- Increased Fuel Efficiency: Reduced rolling resistance due to proper alignment improves fuel efficiency.

- Enhanced Safety: Correct alignment contributes to overall vehicle safety by ensuring proper braking and steering response.

6. Describe the process of wheel balancing and its benefits?

- Detection of Imbalances: The wheel is placed on a balancing machine to identify any weight imbalances.

- Weight Placement: Small weights are strategically placed on the wheel to counteract the imbalances.

- Reduced Vibrations: Balanced wheels minimize vibrations, resulting in a smoother and more comfortable ride.

- Improved Tire Life: Reduced vibrations prevent excessive tire wear, increasing tire longevity.

7. Discuss the technological advancements in wheel design and manufacturing?

- Advanced Materials: Lightweight and durable materials like carbon fiber and titanium are used to enhance performance.

- Computer-aided Design: Engineers use software to optimize wheel designs, reducing weight and improving strength.

- Additive Manufacturing: 3D printing allows for complex and customized wheel designs, enabling tailored solutions.

- Smart Wheels: Sensors embedded in wheels can monitor tire pressure, temperature, and other parameters, improving safety and convenience.

8. What are the current trends and challenges in the automotive wheel industry?

- Sustainability: Focus on eco-friendly materials and manufacturing practices to reduce environmental impact.

- Lightweighting: Demand for lightweight wheels to improve fuel efficiency and performance.

- Customization and Personalization: Growing trend towards customized and aftermarket wheels to cater to individual preferences.

- Advanced Technologies: Integration of smart wheels and other technologies to enhance safety, convenience, and efficiency.

9. What is your understanding of the wheel assembly process?

- Wheel Mounting: Mounting the wheel on the vehicle’s hub.

- Tire Mounting: Installing the tire on the wheel.

- Balancing and Alignment: Ensuring proper balance and alignment for optimal performance.

- Torque Specifications: Tightening the wheel lug nuts to the manufacturer’s specifications.

- Safety Checks: Verifying the integrity of the assembly and ensuring all components are secure.

10. Describe the role of the wheelwright in the automotive industry?

- Wheel Design and Engineering: Designing and developing wheels to meet performance and aesthetic requirements.

- Manufacturing and Quality Control: Overseeing the production process and ensuring the quality of wheels.

- Customer Support: Providing technical advice and support to customers on wheel selection, maintenance, and troubleshooting.

- Industry Collaboration: Working with engineers and designers to integrate wheels effectively into vehicle designs.

- Research and Development: Exploring new technologies and materials to advance wheel design and manufacturing.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wheelwright.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wheelwright‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Wheelwrights are highly skilled craftspeople responsible for the design, construction, repair, and maintenance of wooden wheels and other wooden components used in various industries, such as transportation, agriculture, and construction.

1. Wheel Design and Construction

Collaborate with engineers and designers to determine wheel specifications, materials, and designs.

- Select and prepare appropriate wood species for wheel construction.

- Use specialized tools and techniques to shape, join, and assemble wheel components.

2. Wheel Repair and Maintenance

Inspect wheels for damage, wear, and defects.

- Repair damaged wheels by replacing or repairing spokes, rims, and other components.

- Perform routine maintenance, such as tightening bolts, lubricating bearings, and replacing worn parts.

3. Other Responsibilities

Develop and maintain jigs, fixtures, and other tools for wheel production.

- Supervise and train apprentices and less experienced wheelwrights.

- Maintain a clean and organized work area.

Interview Tips

Preparing for a wheelwright interview requires research, practice, and confidence.

1. Research the Company and Role

Familiarize yourself with the company’s history, values, and products.

- Understand the specific requirements and responsibilities of the wheelwright position.

- Research industry trends and advancements in wheelwright techniques.

2. Practice Common Interview Questions

Prepare answers to common interview questions, such as:

- “Tell me about your experience in wheelwright.”

- “What are your strengths and weaknesses as a wheelwright?”

- “Why are you interested in this position?”

3. Showcase Your Skills and Experience

Highlight your relevant skills and experience in your resume and interview answers.

- Quantify your accomplishments using specific numbers and metrics.

- Provide examples of complex or challenging projects you have worked on.

4. Prepare Industry-Specific Questions

Demonstrate your knowledge of the wheelwright industry by asking thoughtful questions.

- “What is the company’s approach to sustainable wood sourcing?”

- “What are the latest advancements in wheel design and manufacturing?”

- “How does the company ensure the quality and safety of its wheels?”

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wheelwright interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!