Are you gearing up for an interview for a Whip Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Whip Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

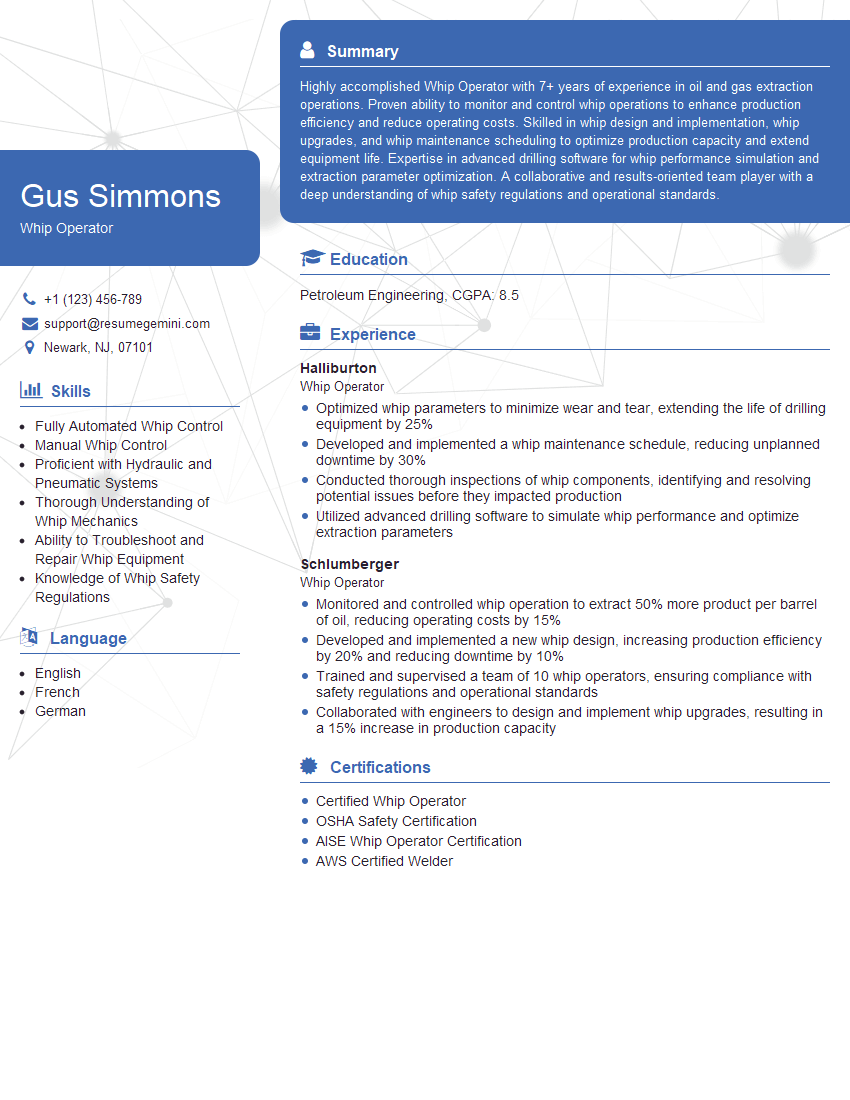

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Whip Operator

1. Can you describe the key responsibilities of a Whip Operator?

As a Whip Operator, my primary responsibilities entail:

- Operating and maintaining whip hoists and cranes used in offshore operations.

- Ensuring the safe and efficient transfer of loads from vessels to platforms and vice versa.

- Monitoring and controlling the movement of loads, utilizing remote controls or manual levers.

- Inspecting and maintaining equipment, identifying any potential issues or malfunctions.

- Communicating effectively with colleagues, supervisors, and vessel personnel to coordinate operations.

- Adhering to all safety protocols and emergency procedures.

2. How do you assess the weight and balance of a load before lifting it?

Load Assessment

- Utilize load charts provided by the manufacturer to determine the maximum load capacity of the whip hoist.

- Estimate the weight of the load visually or through consultation with other personnel.

- Consider the shape, size, and distribution of the load to ensure it can be lifted safely.

- Inspect the load for any loose or unstable components that could shift during lifting.

Balance Assessment

- Determine the center of gravity of the load by considering its shape and distribution.

- Ensure the load is suspended evenly and securely from the whip hoist.

- Monitor the load during lifting to identify any potential imbalances or shifting.

3. What is the proper procedure for attaching a load to the whip hoist?

To securely attach a load to the whip hoist, I follow these steps:

- Inspect the load and lifting equipment (slings, hooks, shackles) for any damage or defects.

- Choose the appropriate slings or lifting equipment based on the load’s weight and shape.

- Attach the slings or lifting equipment to the load securely using proper knots or connections.

- Hook the slings or lifting equipment to the whip hoist’s load hook.

- Ensure the load is balanced and stable before lifting.

4. How do you handle situations where the load is too heavy for the whip hoist?

In such scenarios, I prioritize the safety of personnel and equipment:

- Immediately stop the lifting operation and report the situation to the supervisor or designated personnel.

- Identify alternative lifting methods or equipment suitable for the load’s weight.

- Coordinate with colleagues or seek additional personnel to assist in handling the heavy load.

- Follow established protocols for load distribution or utilization of multiple whip hoists.

5. What are the common mechanical issues that you encounter as a Whip Operator?

During my experience as a Whip Operator, I’ve addressed various mechanical issues including:

- Mechanical failures in whip hoist components (e.g., motor, gearbox, brakes).

- Electrical malfunctions in control systems, wiring, or sensors.

- Hydraulic leaks or pressure issues in hydraulic whip hoists.

- Corrosion or wear in load hooks, slings, or shackles.

- Malfunctioning sensors or indicators related to load weight or position.

6. How do you ensure that the whip hoist and surrounding area are safe before operating it?

To ensure a safe operating environment, I conduct the following checks:

- Inspect the whip hoist thoroughly for any visible damage, leaks, or loose components.

- Check the surrounding area for obstacles, hazards, or potential conflicts.

- Verify that all safety guards and barriers are in place and functioning properly.

- Confirm that the load path is clear and free of any obstructions.

- Ensure proper lighting and visibility in the operating area.

7. What are the key safety protocols that you follow as a Whip Operator?

I strictly adhere to the following safety protocols:

- Never exceed the maximum load capacity of the whip hoist.

- Always maintain a safe distance from the load and lifting zone.

- Use proper hand signals or communication methods to coordinate with colleagues.

- Inspect and maintain equipment regularly to identify and address potential issues.

- Follow established emergency procedures in case of any malfunctions or accidents.

8. How do you handle emergencies or unexpected events during whip hoist operations?

In the event of emergencies, I prioritize the safety of personnel and equipment:

- Immediately stop the operation and alert the supervisor or designated personnel.

- Identify the source of the emergency and take appropriate action to mitigate the situation.

- Evacuate the area if necessary and follow established emergency protocols.

- Report the incident and cooperate with investigations to prevent similar occurrences.

9. What techniques do you use to minimize wear and tear on the whip hoist and its components?

To extend the lifespan of the whip hoist and its components, I employ the following techniques:

- Operate the whip hoist within its specified load capacity and operating parameters.

- Perform regular inspections and maintenance to identify and address potential issues early on.

- Lubricate moving parts and components as per manufacturer’s recommendations.

- Handle loads smoothly and avoid sudden jerks or excessive force.

- Store the whip hoist properly when not in use to protect it from environmental factors.

10. Can you describe a situation where you successfully handled a challenging whip hoist operation?

In one instance, I was tasked with lifting a heavy piece of equipment from a vessel to an offshore platform. The load was particularly large and required precise handling.

I carefully assessed the weight and balance of the load, selected the appropriate slings and lifting equipment, and attached them securely. I coordinated with colleagues to ensure a clear load path and maintained constant communication throughout the operation.

Despite strong winds and limited visibility, I successfully lifted and transferred the load to the platform without any incidents. My attention to detail, adherence to safety protocols, and effective communication played a crucial role in the successful completion of this challenging task.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Whip Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Whip Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Whip Operators are responsible for operating and maintaining the whip in a manufacturing or production environment. Their primary duties involve monitoring and controlling the movement of materials or products through the whip, ensuring smooth and efficient production processes.

1. Whip Operation

Whip Operators are the primary operators of the whip, a machine that is used to move materials or products along a production line. They are responsible for controlling the speed, direction, and tension of the whip to ensure that the materials or products are moved safely and efficiently.

- Operate the whip to move materials or products along a production line.

- Control the speed, direction, and tension of the whip.

- Monitor the whip for any problems or malfunctions.

2. Whip Maintenance

Whip Operators are also responsible for maintaining the whip in good working condition. This includes inspecting the whip for any damage or wear, cleaning the whip, and lubricating the moving parts.

- Inspect the whip for any damage or wear.

- Clean the whip.

- Lubricate the moving parts.

3. Troubleshooting

Whip Operators are also responsible for troubleshooting any problems that may occur with the whip. This may involve identifying the source of the problem, repairing the problem, or calling for assistance.

- Identify the source of the problem.

- Repair the problem.

- Call for assistance.

4. Safety

Whip Operators must follow all safety procedures and regulations. This includes wearing appropriate safety gear, being aware of their surroundings, and operating the whip safely.

- Wear appropriate safety gear.

- Be aware of their surroundings.

- Operate the whip safely.

Interview Tips

Preparing for an interview for a Whip Operator position requires a comprehensive approach that encompasses both technical knowledge and soft skills. Here are some tips to help candidates ace their interview:

1. Research the Company and the Position

Before attending the interview, candidates should gründlich research the company and the specific Whip Operator position they are applying for. This includes gathering information about the company’s products or services, its industry, its culture, and the specific responsibilities of the role.

- Visit the company’s website and social media pages.

- Read industry news and articles.

- Talk to people in your network who work for the company.

2. Practice Your Answers to Common Interview Questions

There are several common interview questions that candidates can expect to be asked, such as “Tell me about yourself,” “Why are you interested in this position?” and “What are your strengths and weaknesses?” Candidates should prepare their answers to these questions in advance and practice delivering them concisely and confidently.

- Use the STAR method to answer behavioral questions.

- Tailor your answers to the specific job you are applying for.

- Practice your answers with a friend or family member.

3. Highlight Your Relevant Skills and Experience

Candidates should emphasize their relevant skills and experience in their resume and during the interview. This includes both hard skills, such as operating and maintaining whips, and soft skills, such as teamwork and communication. Candidates should also be prepared to discuss their experience in troubleshooting whip problems and ensuring safety.

- Quantify your accomplishments whenever possible.

- Use action verbs to describe your skills and experience.

- Be prepared to give specific examples of your work.

4. Be Enthusiastic and Positive

Candidates should convey their enthusiasm for the position and their positive attitude during the interview. They should be mindful of their body language and make eye contact with the interviewer. Candidates should also be prepared to ask questions about the company and the position, which demonstrates their interest and engagement.

- Smile and make eye contact.

- Speak clearly and confidently.

- Ask thoughtful questions about the company and the position.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Whip Operator interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.