Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted White Metal Caster position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

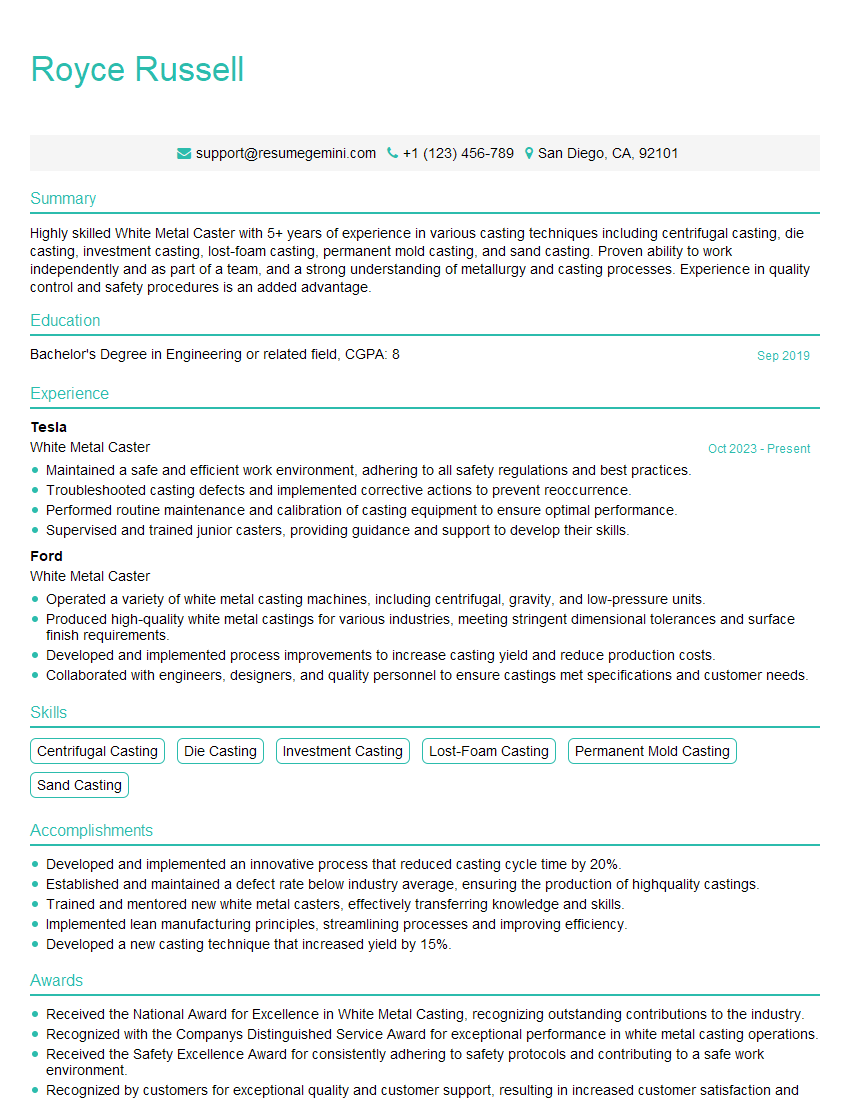

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For White Metal Caster

1. What are the responsibilities of a White Metal Caster?

As a White Metal Caster, my responsibilities typically include:

- Melting and casting white metal into molds to create various components and parts.

- Preparing and maintaining casting equipment, including furnaces, molds, and casting machines.

- Checking the quality of castings, identifying defects, and making adjustments to the casting process as needed.

- Maintaining a clean and organized work area, observing safety protocols, and adhering to quality standards.

2. Describe the process of casting white metal.

Mold preparation

- Prepare the mold by cleaning and applying a release agent to prevent the casting from sticking.

- Secure the mold halves together and ensure proper alignment.

Metal preparation

- Melt the white metal in a furnace to the appropriate temperature.

- Degas the molten metal to remove impurities and ensure a sound casting.

Pouring and solidification

- Pour the molten metal into the mold cavity carefully to avoid splashing or air entrapment.

- Allow the metal to solidify completely before removing the casting from the mold.

3. What are the different types of white metal casting processes?

- Gravity casting: Using gravity to fill the mold cavity with molten metal.

- Pressure casting: Applying pressure to force the molten metal into the mold cavity.

- Centrifugal casting: Spinning the mold to distribute the molten metal evenly.

- Vacuum casting: Evacuating air from the mold cavity to improve filling and prevent porosity.

4. How do you ensure the quality of white metal castings?

- Visual inspection: Examining the casting for defects such as cracks, voids, and surface imperfections.

- Dimensional measurement: Verifying that the casting meets the specified dimensions using measuring tools.

- Mechanical testing: Conducting tests to assess the strength, hardness, and other mechanical properties of the casting.

- Non-destructive testing: Using techniques such as radiography and ultrasonic testing to detect internal defects.

5. What are the common defects that can occur in white metal castings?

- Shrinkage cavities: Hollows caused by the solidification and contraction of the metal.

- Gas porosity: Bubbles trapped in the casting due to gas entrapment during pouring.

- Cold shuts: Areas where the molten metal has not completely fused together.

- Cracks: Breaks in the casting caused by thermal stresses or mechanical forces.

- Misruns: Incomplete filling of the mold cavity due to insufficient molten metal.

6. How do you prevent defects in white metal castings?

- Proper mold design: Ensuring that the mold is designed to facilitate proper filling and solidification.

- Accurate pouring temperature: Selecting the correct temperature for pouring to minimize shrinkage defects.

- Degassing: Removing impurities from the molten metal to prevent gas porosity.

- Controlled cooling: Allowing the casting to cool slowly and evenly to minimize thermal stresses.

- Proper mold release agents: Using suitable release agents to prevent sticking and ensure clean castings.

7. What safety precautions should be taken when working with white metal?

- Protective clothing: Wearing heat-resistant gloves, apron, and safety glasses.

- Ventilation: Ensuring adequate ventilation to remove fumes and gases generated during casting.

- Hot metal handling: Using proper tools and techniques to handle molten metal safely.

- Fire safety: Having fire extinguishers and other safety equipment readily available.

- Training: Receiving proper training on safety procedures and equipment operation.

8. What are your experiences in white metal casting?

In my previous role as a White Metal Caster, I was responsible for:

- Operating various casting machines, including gravity and pressure casting equipment.

- Casting white metal components for automotive, aerospace, and industrial applications.

- Maintaining and calibrating casting equipment to ensure accuracy and efficiency.

- Identifying and resolving casting defects, improving casting quality and yield.

- Working effectively in a team environment, coordinating with other departments to meet production goals.

9. How do you stay updated with advancements in white metal casting?

- Industry publications: Reading trade magazines and journals to keep abreast of new technologies and best practices.

- Conferences and seminars: Attending industry events to learn from experts and network with peers.

- Online resources: Utilizing websites, forums, and technical databases to access the latest information.

- Collaboration with suppliers: Consulting with material suppliers and equipment manufacturers to gain insights into product advancements.

10. Why are you interested in working as a White Metal Caster in our company?

I am eager to join your company as a White Metal Caster because:

- Your company has a strong reputation in the industry for producing high-quality white metal castings.

- The position aligns with my skills and experience in white metal casting.

- I am keen to contribute to your company’s success by leveraging my technical expertise and commitment to quality.

- I am confident that I can make a significant contribution to your team and support your production goals.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for White Metal Caster.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the White Metal Caster‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A White Metal Caster is responsible for the production of white metal castings. This involves setting up and operating casting equipment, pouring molten metal into molds, and removing finished castings.

1. Setup and Operate Casting Equipment

To ensure efficient and safe casting operations, it is important to properly set up and operate the casting equipment. This includes setting up and calibrating casting machines, preparing molds, and ensuring that the equipment is in good working condition.

- Set up and calibrate casting machines according to specifications.

- Prepare molds by cleaning, lubricating, and assembling them.

- Inspect equipment regularly to ensure that it is in good working condition.

- Troubleshoot and resolve any issues with casting equipment.

2. Pour Molten Metal into Molds

Pouring molten metal into molds is a critical step in the casting process, as it requires precision and safety. White Metal Casters must be able to accurately pour the molten metal into the molds without spilling or causing any defects.

- Wear appropriate protective gear, including gloves, safety glasses, and a face shield.

- Use a ladle or crucible to carefully pour molten metal into the molds.

- Control the pouring rate and temperature to ensure that the metal fills the mold properly.

- Inspect the poured metal for any defects or irregularities.

3. Remove Finished Castings

Once the molten metal has solidified, the finished castings must be removed from the molds. White Metal Casters must be able to carefully remove the castings without damaging them.

- Allow the castings to cool and solidify completely.

- Break open the molds and carefully remove the castings.

- Inspect the castings for any defects or irregularities.

- Clean and prepare the castings for further processing or shipment.

4. Maintain a Clean and Safe Work Area

Maintaining a clean and safe work area is essential for the efficient and safe operation of a casting facility. White Metal Casters must be able to keep their work area clean and organized, and they must be aware of and follow all safety protocols.

- Keep the work area clean and free of debris.

- Properly dispose of waste materials and hazardous substances.

- Follow all safety protocols, including wearing appropriate protective gear.

- Report any accidents or unsafe conditions to a supervisor.

Interview Tips

To ace an interview for a White Metal Caster position, it’s important to be well-prepared and to demonstrate your technical skills and knowledge. Here are some tips to help you prepare for the interview:

1. Research the Company and the Position

Before the interview, take the time to research the company and the specific position you’re applying for. This will help you to understand the company’s culture, values, and goals, as well as the specific requirements of the job.

- Visit the company’s website to learn about their history, products, and services.

- Read industry news and articles to stay up-to-date on the latest trends.

- Network with people in the industry to get insights into the company and the position.

2. Practice Your Technical Skills

As a White Metal Caster, you’ll need to have a strong understanding of the casting process and be able to demonstrate your technical skills. Practice setting up and operating casting equipment, pouring molten metal into molds, and removing finished castings.

- Set up a casting machine and practice pouring molten metal into molds.

- Practice removing finished castings from molds and inspecting them for defects.

- Take a course or workshop on casting techniques.

3. Prepare for Behavioral Interview Questions

In addition to technical questions, you’re likely to be asked behavioral interview questions during your interview. These questions are designed to assess your soft skills, such as your teamwork, communication, and problem-solving abilities.

- Prepare for common behavioral interview questions by thinking about specific examples from your work experience.

- Use the STAR method (Situation, Task, Action, Result) to answer behavioral interview questions.

- Practice answering behavioral interview questions with a friend or family member.

4. Dress Professionally and Arrive on Time

First impressions matter, so it’s important to dress professionally for your interview. Arrive on time for your interview and be prepared to make a good impression on the interviewer.

- Wear a suit or business casual attire.

- Be on time for your interview.

- Be polite and respectful to the interviewer.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the White Metal Caster interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.