Are you gearing up for an interview for a Whitesmith position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Whitesmith and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

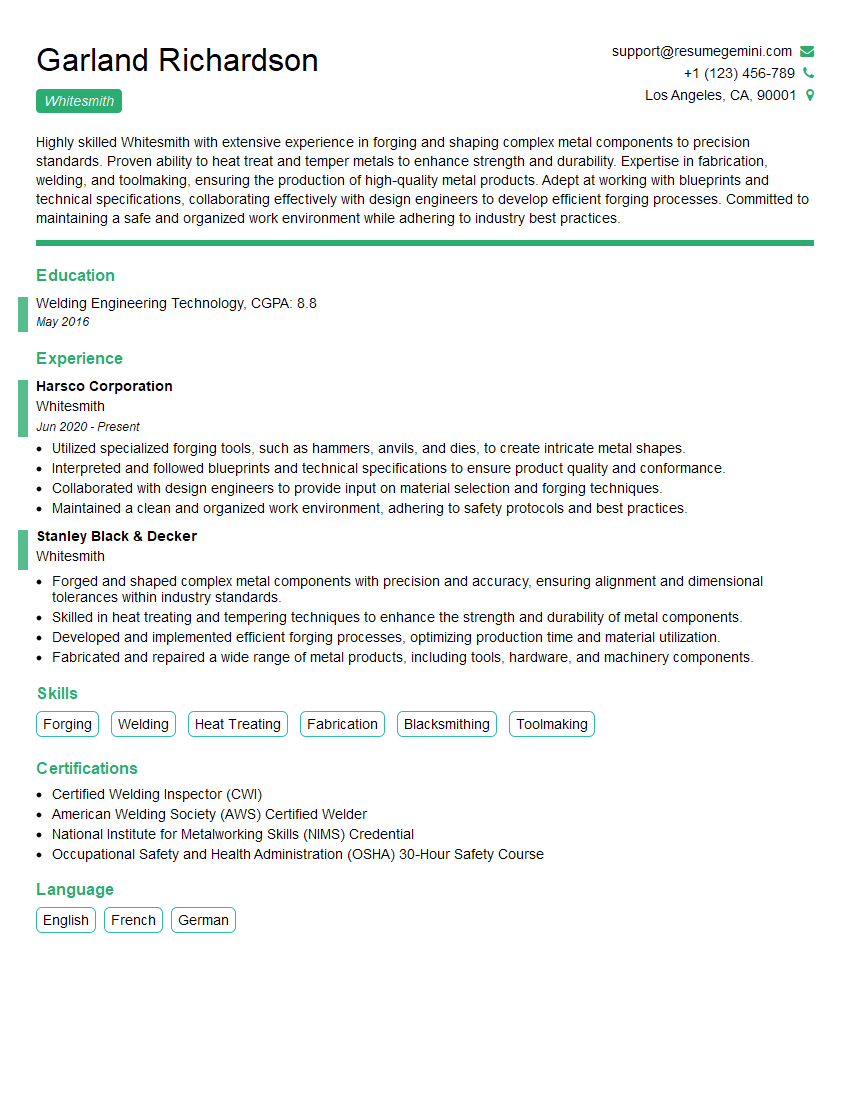

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Whitesmith

1. What is the difference between a whitesmith and a blacksmith?

A whitesmith is a metalworker who specializes in the fabrication of tin, iron, copper, and other white metals. A blacksmith, on the other hand, is a metalworker who specializes in the fabrication of iron. Whitesmiths typically use lighter tools and techniques than blacksmiths, and they often work with sheet metal rather than solid metal.

2. What are the different types of whitesmithing techniques?

Forging

- Forging is the process of shaping metal by heating it and hammering it into the desired shape. Whitesmiths can use a variety of forging techniques, including hand forging, drop forging, and press forging.

Soldering

- Soldering is the process of joining two pieces of metal together using a molten metal alloy called solder. Whitesmiths can use a variety of soldering techniques, including soft soldering, hard soldering, and brazing.

Welding

- Welding is the process of joining two pieces of metal together by melting them together. Whitesmiths can use a variety of welding techniques, including arc welding, gas welding, and resistance welding.

3. What are the different types of whitesmithing tools?

- Anvil: A heavy block of metal on which metal is hammered into shape.

- Forge: A furnace used to heat metal for forging.

- Hammer: A tool used to strike metal and shape it.

- Pliers: A tool used to hold and manipulate metal.

- Soldering iron: A tool used to melt solder and join metal together.

- Welding torch: A tool used to melt metal and join it together.

4. What are the different types of whitesmithing projects?

- Cooking utensils: Whitesmiths can make a variety of cooking utensils, such as pots, pans, and skillets.

- Lighting fixtures: Whitesmiths can make a variety of lighting fixtures, such as chandeliers, sconces, and lamps.

- Furniture: Whitesmiths can make a variety of furniture, such as chairs, tables, and beds.

- Decorative items: Whitesmiths can make a variety of decorative items, such as sculptures, jewelry, and picture frames.

5. What are the challenges of whitesmithing?

- Whitesmithing can be a physically demanding job, as it requires a great deal of strength and endurance.

- Whitesmiths must be able to work with precision and accuracy, as even small mistakes can ruin a project.

- Whitesmiths must be able to work with a variety of tools and materials, and they must be able to adapt to different working conditions.

6. What are the rewards of whitesmithing?

- Whitesmithing can be a very rewarding job, as it allows you to create beautiful and functional objects with your own hands.

- Whitesmithing is a trade that is in high demand, so you can be sure of finding work if you are skilled in this trade.

- Whitesmithing is a challenging but rewarding career that can provide you with a sense of accomplishment and satisfaction.

7. What are your strengths as a whitesmith?

I am a highly skilled whitesmith with over 10 years of experience in the trade. I am proficient in all aspects of whitesmithing, including forging, soldering, welding, and finishing. I am also a certified welder and have a strong understanding of metalworking principles.

8. What are your weaknesses as a whitesmith?

I am always looking for ways to improve my skills, but I would say that my biggest weakness is my lack of experience in working with large-scale projects. However, I am eager to learn and I am confident that I can quickly develop the skills necessary to work on larger projects.

9. What are your career goals as a whitesmith?

My career goal is to become a master whitesmith. I want to continue to develop my skills and knowledge in this trade, and I eventually hope to start my own whitesmithing business.

10. Why do you want to work for our company?

I am very interested in working for your company because I am impressed by your commitment to quality and craftsmanship. I believe that my skills and experience would be a valuable asset to your team, and I am eager to learn from your experienced whitesmiths.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Whitesmith.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Whitesmith‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Whitesmiths, also known as blacksmiths, are skilled artisans who work with ferrous metals, particularly iron and steel. They use various tools and techniques to shape, forge, and weld metal into a wide range of products, from structural components to decorative pieces.

1. Shaping and Forging

Whitesmiths use hammers, anvils, and other tools to shape and forge metal into desired forms. They heat the metal to high temperatures, making it malleable and easier to work with. They then use various techniques, such as hammering, bending, and welding, to create the desired shape and size.

2. Welding and Joining

Whitesmiths use different welding techniques, such as arc welding, gas welding, and forge welding, to join pieces of metal together. They ensure strong and durable connections between components by carefully preparing the metal surfaces and applying the appropriate welding process.

3. Heat Treatment

Whitesmiths perform heat treatment processes to alter the properties of metal, such as its strength, hardness, and flexibility. They control the temperature and duration of heating and cooling cycles to achieve the desired material characteristics.

4. Design and Development

Whitesmiths may be involved in the design and development of metal products. They work with engineers, designers, and other stakeholders to create new products or improve existing ones. Their knowledge of metal properties and fabrication techniques allows them to contribute to the design process.

Interview Tips

Preparing for an interview for a whitesmith position requires a combination of technical knowledge and soft skills. Here are some tips to help you ace your interview:

1. Research the Company and Position

Before the interview, thoroughly research the company and the specific whitesmith position you’re applying for. This will give you insights into their business, culture, and the requirements of the role. It will also demonstrate your enthusiasm and interest in the opportunity.

2. Showcase Your Technical Skills

During the interview, be prepared to discuss your technical abilities and experience in whitesmithing. Highlight your proficiency in metalworking techniques, welding methods, and heat treatment processes. Bring examples of your work or projects to showcase your skills and craftsmanship.

3. Emphasize Your Attention to Detail

Whitesmithing requires a high level of precision and attention to detail. In your interview, emphasize your ability to work accurately and meticulously. Share examples where you effectively followed specifications and achieved high-quality results in your work.

4. Highlight Your Safety Consciousness

Working with metal and equipment requires a strong safety consciousness. During the interview, discuss your safety practices and knowledge of industry regulations. Demonstrate your commitment to maintaining a safe work environment and following safety protocols.

5. Practice Common Interview Questions

Familiarize yourself with common interview questions related to the whitesmith profession. Practice answering questions about your experience, skills, and why you’re interested in the position. Prepare well-structured and specific responses that highlight your strengths and qualifications.

6. Be Enthusiastic and Professional

Throughout the interview, maintain a positive and professional demeanor. Express your enthusiasm for whitesmithing and the opportunity to contribute to the company. Demonstrate your passion for the craft and your desire to learn and grow in the field.

Next Step:

Now that you’re armed with the knowledge of Whitesmith interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Whitesmith positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini