Are you gearing up for a career in Wind Tunnel Mechanic? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Wind Tunnel Mechanic and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

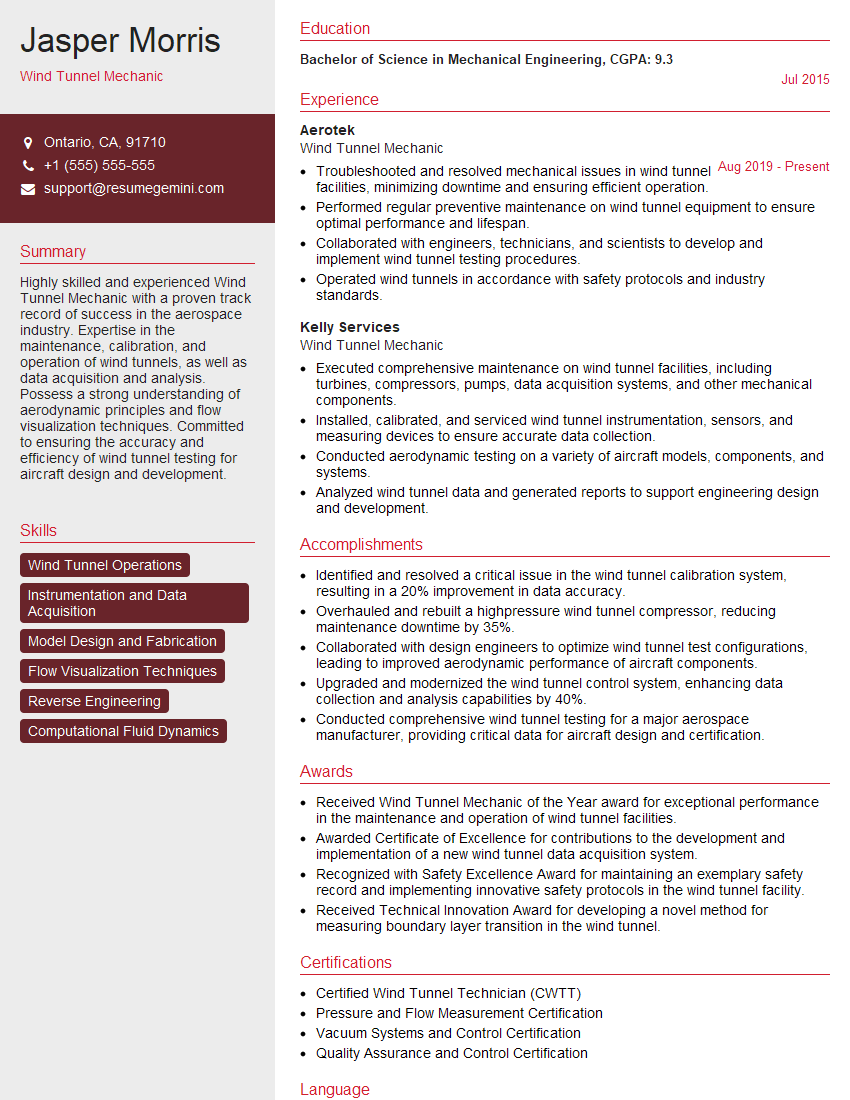

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wind Tunnel Mechanic

1. Describe the key components of a wind tunnel and explain their functions.

A wind tunnel is a device used to study the effects of air flowing around objects. The key components of a wind tunnel include:

- The test section: This is the section of the wind tunnel where the object being tested is placed. The test section is typically made of clear material so that the flow of air around the object can be observed.

- The fan: The fan is used to generate the flow of air in the wind tunnel. The fan is typically located at the upstream end of the wind tunnel.

- The diffuser: The diffuser is used to slow down the flow of air in the wind tunnel. The diffuser is typically located at the downstream end of the wind tunnel.

- The control system: The control system is used to control the speed of the fan and the angle of attack of the object being tested.

2. Explain the different types of wind tunnels and their applications.

Open-circuit wind tunnels:

- Most common type of wind tunnel

- Air is drawn through the tunnel by a fan and exhausted to the atmosphere

- Used for a wide variety of testing, including aerodynamic testing of aircraft, cars, and buildings

Closed-circuit wind tunnels:

- Air is circulated in a closed loop

- Used for testing at very high or very low speeds

- Also used for testing in controlled environments, such as low-pressure or high-temperature conditions

3. Describe the different types of measurements that can be made in a wind tunnel.

The different types of measurements that can be made in a wind tunnel include:

- Pressure measurements: Pressure measurements can be used to determine the pressure distribution around an object. Pressure measurements can be made using pressure transducers or pressure taps.

- Velocity measurements: Velocity measurements can be used to determine the velocity of the air flowing around an object. Velocity measurements can be made using anemometers or hot-wire anemometers.

- Temperature measurements: Temperature measurements can be used to determine the temperature of the air flowing around an object. Temperature measurements can be made using thermocouples or resistance temperature detectors.

- Force measurements: Force measurements can be used to determine the forces acting on an object in a wind tunnel. Force measurements can be made using force transducers or strain gauges.

4. Explain the importance of calibration in wind tunnel testing.

Calibration is important in wind tunnel testing to ensure that the measurements made in the wind tunnel are accurate. Calibration involves comparing the measurements made in the wind tunnel to known values. This allows the wind tunnel to be adjusted so that the measurements made in the wind tunnel are accurate.

5. Describe the different types of models that can be used in wind tunnel testing.

The different types of models that can be used in wind tunnel testing include:

- Physical models: Physical models are three-dimensional representations of the object being tested. Physical models can be made from a variety of materials, including wood, metal, and plastic.

- CFD models: CFD models are computer models that simulate the flow of air around an object. CFD models can be used to predict the aerodynamic performance of an object before it is built.

- Hybrid models: Hybrid models combine physical models and CFD models. Hybrid models can be used to improve the accuracy of CFD models.

6. Explain the different types of flow regimes that can occur in a wind tunnel.

The different types of flow regimes that can occur in a wind tunnel include:

- Laminar flow: Laminar flow is characterized by smooth, orderly flow. Laminar flow occurs at low Reynolds numbers.

- Turbulent flow: Turbulent flow is characterized by chaotic, disordered flow. Turbulent flow occurs at high Reynolds numbers.

- Transitional flow: Transitional flow is the region between laminar flow and turbulent flow. Transitional flow occurs at intermediate Reynolds numbers.

7. Describe the different types of boundary layer control techniques.

The different types of boundary layer control techniques include:

- Passive boundary layer control: Passive boundary layer control techniques do not require any external energy input. Passive boundary layer control techniques include using vortex generators and turbulators.

- Active boundary layer control: Active boundary layer control techniques require external energy input. Active boundary layer control techniques include using suction and blowing.

8. Explain the importance of wind tunnel testing in the design of aircraft.

Wind tunnel testing is important in the design of aircraft because it allows engineers to study the aerodynamic performance of an aircraft before it is built. Wind tunnel testing can be used to determine the lift, drag, and stability of an aircraft. Wind tunnel testing can also be used to study the effects of different design changes on the aerodynamic performance of an aircraft.

9. Describe the different types of wind tunnel facilities available.

The different types of wind tunnel facilities available include:

- Low-speed wind tunnels: Low-speed wind tunnels are used to test objects at speeds up to about 100 mph.

- Transonic wind tunnels: Transonic wind tunnels are used to test objects at speeds up to about 1,200 mph.

- Supersonic wind tunnels: Supersonic wind tunnels are used to test objects at speeds up to about 5,000 mph.

- Hypersonic wind tunnels: Hypersonic wind tunnels are used to test objects at speeds up to about 10,000 mph.

10. Explain the role of wind tunnel testing in the development of new technologies.

Wind tunnel testing plays a critical role in the development of new technologies. Wind tunnel testing can be used to study the aerodynamic performance of new designs and to identify potential problems. Wind tunnel testing can also be used to develop new technologies, such as new aircraft designs and new wind energy technologies.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wind Tunnel Mechanic.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wind Tunnel Mechanic‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Wind Tunnel Mechanic is responsible for the maintenance, repair, and operation of wind tunnels and auxiliary equipment. They ensure that the wind tunnels operate safely and efficiently, and they perform regular inspections and calibrations to maintain accuracy.

1. Maintenance and Repair

Wind Tunnel Mechanics are responsible for the upkeep of all wind tunnel components, including fans, motors, and instrumentation. They perform routine maintenance tasks such as lubrication, cleaning, and replacement of worn parts. In addition, they troubleshoot and repair any malfunctions that may occur.

2. Operation

Wind Tunnel Mechanics are also responsible for operating the wind tunnels. They set up the test section, control the airflow, and monitor the data acquisition system. They also ensure that all safety procedures are followed.

3. Inspection and Calibration

Wind Tunnel Mechanics perform regular inspections of the wind tunnel and its components to ensure that everything is in good working order. They also calibrate the instrumentation to ensure that the data collected is accurate.

4. Safety

Wind Tunnel Mechanics are responsible for ensuring the safety of everyone in the wind tunnel facility. They follow all safety procedures and wear appropriate safety gear.

Interview Tips

Preparing for an interview for a Wind Tunnel Mechanic position can be a daunting task, but with the right preparation, you can increase your chances of success.

1. Research the company and the position

Before you go to your interview, take some time to research the company and the position you are applying for. This will help you understand the company’s culture and values, as well as the specific requirements of the job.

2. Practice your answers to common interview questions

There are a number of common interview questions that you are likely to be asked, such as “Tell me about yourself” and “Why are you interested in this position?” Practice your answers to these questions in advance so that you can deliver them confidently and concisely.

3. Be prepared to talk about your experience and skills

The interviewer will want to know about your experience and skills as a Wind Tunnel Mechanic. Be prepared to talk about your experience in detail, including your responsibilities and accomplishments. Also, be sure to highlight any skills that are relevant to the position, such as your ability to troubleshoot and repair wind tunnels.

4. Ask questions about the company and the position

Asking questions at the end of the interview shows that you are interested in the position and the company. It also gives you a chance to get more information about the job and the company culture. Prepare a few questions in advance so that you can ask them at the end of the interview.

5. Follow up after the interview

After the interview, be sure to send a thank-you note to the interviewer. This is a simple way to show your appreciation for their time and consideration.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wind Tunnel Mechanic interview with confidence. Remember, a well-crafted resume is your first impression. Take the time to tailor your resume to highlight your relevant skills and experiences. And don’t forget to practice your answers to common interview questions. With a little preparation, you’ll be on your way to landing your dream job. So what are you waiting for? Start building your resume and start applying! Build an amazing resume with ResumeGemini.