Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Wind Up Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

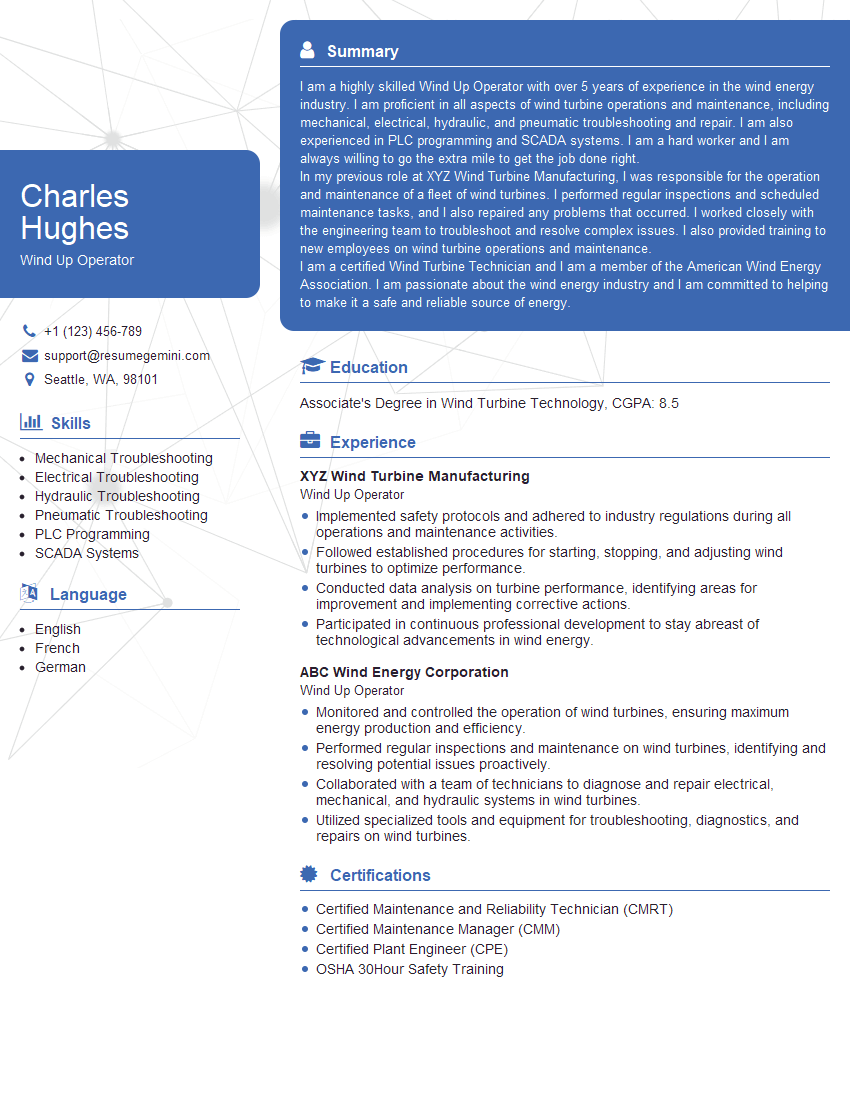

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Wind Up Operator

1. Explain the principle operation of a wind up machine?

A wind up machine is a device used to wind up a coil or wire onto a bobbin or spool. The principle of operation is based on the transfer of mechanical energy from a motor or hand crank to the coil or wire, causing it to rotate and wind onto the bobbin or spool.

- The machine consists of a rotating spindle or arbor that holds the bobbin or spool.

- The coil or wire is fed into the machine and guided onto the bobbin or spool.

- The rotation of the spindle or arbor causes the coil or wire to wrap around the bobbin or spool, creating a wound coil.

- The tension of the coil or wire is controlled to ensure proper winding and prevent tangling or breakage.

- The wind up machine can be manually operated with a hand crank or powered by an electric motor for automated operation.

2. Describe the different types of wind up machines and their applications?

Manual Wind Up Machines

- Operated by hand crank.

- Suitable for small-scale winding applications or prototyping.

- offer limited speed and precision.

Semi-Automatic Wind Up Machines

- Powered by an electric motor.

- Controlled by a foot pedal or switch.

- Allow for faster winding speeds and improved precision.

Fully Automatic Wind Up Machines

- Computer-controlled.

- Capable of high-volume production.

- Offer high accuracy and repeatability.

3. What are the key parameters to consider when selecting a wind up machine?

- Winding speed: The speed at which the coil or wire is wound.

- Coil or wire size: The diameter and length of the coil or wire to be wound.

- Bobbin or spool size: The dimensions of the bobbin or spool used for winding.

- Tension control: The ability to control the tension of the coil or wire during winding.

- Automation level: The degree of automation required, from manual to fully automatic.

- Accuracy and precision: The tolerance and repeatability of the winding process.

4. Explain the process of setting up and operating a wind up machine?

- Install the bobbin or spool onto the spindle or arbor.

- Feed the coil or wire into the machine and guide it onto the bobbin or spool.

- Set the winding parameters, such as speed, tension, and winding direction.

- Start the winding process and monitor the progress.

- Once the winding is complete, remove the wound coil from the machine.

5. What are the common troubleshooting techniques for wind up machine malfunctions?

- Check for wire tangles or breaks.

- Adjust the tension settings.

- Clean the machine and remove any debris.

- Inspect the electrical connections.

- Refer to the manufacturer’s manual for specific troubleshooting steps.

6. Describe the safety precautions to follow when operating a wind up machine?

- Wear appropriate safety gear, such as gloves and safety glasses.

- Keep hands and loose clothing away from moving parts.

- Do not operate the machine if it is damaged or malfunctioning.

- Follow the manufacturer’s instructions for safe operation.

- Be aware of the potential for electrical hazards.

7. What are the maintenance tasks required to keep a wind up machine in good working condition?

- Regular cleaning and lubrication.

- Inspection of electrical components.

- Calibration and adjustment of winding parameters.

- Replacement of worn or damaged parts.

- Following the manufacturer’s recommended maintenance schedule.

8. Explain the role of quality control in wind up machine operations?

- Ensuring the accuracy and precision of winding.

- Preventing defects and maintaining product quality.

- Testing wound coils for electrical and mechanical properties.

- Identifying and correcting any process deviations.

- Implementing quality control measures to meet customer specifications.

9. Describe the advancements in wind up machine technology?

- Automated winding processes.

- Computer-controlled winding parameters.

- High-speed winding capabilities.

- Improved tension control systems.

- Integration with other manufacturing processes.

10. How do you stay updated with the latest developments in wind up machine technology?

- Attending industry conferences and exhibitions.

- Reading technical journals and publications.

- Consulting with equipment manufacturers and suppliers.

- Participating in online forums and discussion groups.

- Seeking training and certification opportunities.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Wind Up Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Wind Up Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities of a Wind Up Operator

A Wind Up Operator plays a crucial role in the manufacturing industry, ensuring the smooth and efficient production of products. This position requires a combination of technical proficiency and attention to detail.

1. Monitoring and Maintaining Machinery

Wind Up Operators are responsible for monitoring and maintaining the winding machinery, including regular inspections and adjustments to ensure optimal performance.

- Conduct routine inspections to identify any potential issues or malfunctions.

- Perform preventive maintenance tasks, such as cleaning, lubrication, and tightening bolts, to minimize downtime.

2. Operating and Controlling Winding Process

Operators handle the winding process, ensuring the proper tension, speed, and alignment of the materials being wound.

- Load and unload materials onto the winding machine.

- Set and adjust machine parameters based on production specifications.

- Monitor the winding process to ensure consistent quality and avoid defects.

3. Quality Control and Inspection

Wind Up Operators play a crucial role in maintaining product quality by conducting visual and physical inspections of the finished products.

- Inspect wound products for defects, such as breaks, uneven winding, or incorrect tension.

- Record and report any quality deviations to supervisors or quality control personnel.

4. Safety and Housekeeping

Safety is paramount in the manufacturing industry, and Wind Up Operators are responsible for maintaining a safe work environment.

- Follow established safety procedures and wear appropriate personal protective equipment.

- Maintain a clean and organized work area to minimize hazards and ensure efficient operations.

Interview Preparation Tips for Wind Up Operator

Preparing for a Wind Up Operator interview requires a combination of research, practice, and confidence. Here are some tips to help candidates ace this interview.

1. Research the Company and Position

Thoroughly research the company’s website, industry publications, and social media pages to gain insights into their business operations, culture, and specific requirements for a Wind Up Operator.

- Identify key responsibilities and qualifications outlined in the job description.

- Note any specific industry terms or technical requirements.

2. Highlight Relevant Experience and Skills

Tailor your resume and cover letter to emphasize your relevant experience and skills.

- Quantify your accomplishments and provide specific examples of your contributions.

- Highlight your technical abilities, such as machinery operation, maintenance, and quality control procedures.

3. Practice Answering Common Interview Questions

Prepare for common interview questions that may be asked, such as:

- “Tell me about your experience with winding machinery.”

- “How do you maintain quality standards in a manufacturing environment?”

- “Describe a time when you identified and resolved a problem on the production line.”

4. Dress Professionally and Arrive on Time

First impressions matter in an interview. Dress professionally and arrive on time to demonstrate your respect for the interviewer and the company.

- Wear clean and ironed business attire.

- Be punctual and allow ample time to find the interview location.

5. Confidence and Enthusiasm

Confidence and enthusiasm are essential for success in any interview. Project a positive attitude and convey your genuine interest in the position.

- Make eye contact, smile, and speak clearly with conviction.

- Express your enthusiasm for the opportunity and the company’s mission.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Wind Up Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!