Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Winder Fixer position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together

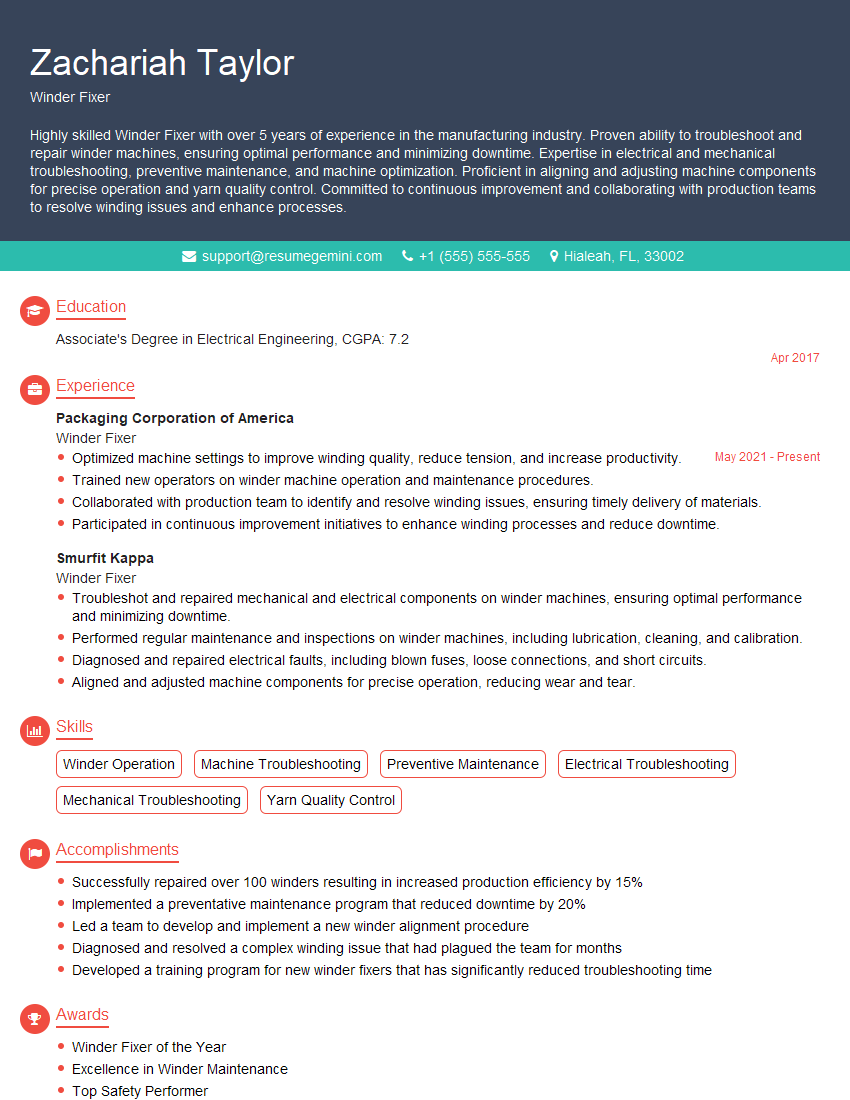

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winder Fixer

1. What are the primary responsibilities of a Winder Fixer?

The primary responsibilities of a Winder Fixer include:

- Inspecting and repairing winding machines to ensure optimal performance.

- Diagnosing mechanical and electrical faults in winding machines.

- Adjusting and calibrating winding parameters to optimize yarn quality.

- Maintaining inventory of spare parts and materials.

- Maintaining a clean and safe work area.

2. Describe the different types of winding machines you have worked on and your experience with them.

I have experience working with a variety of winding machines, including:

Cone Winders

- Able to operate Schlafhorst Autoconer and Savio Orion machines.

- Proficient in troubleshooting and repairing mechanical and electrical issues.

Ring Winders

- Experience with Rieter R1 and Zinser Impact winding machines.

- Skillful in adjusting tension and traverse settings for optimal yarn quality.

3. What are the safety precautions that must be taken when working on winding machines?

When working on winding machines, it is crucial to adhere to the following safety precautions:

- Wear appropriate safety gear, including gloves, safety glasses, and earplugs.

- Ensure that the machine is turned off and disconnected from power before performing any maintenance.

- Be aware of moving parts and potential hazards.

- Follow lockout/tagout procedures when working on electrical components.

- Report any safety concerns or potential hazards to a supervisor immediately.

4. How do you diagnose and troubleshoot common winding machine problems?

To diagnose and troubleshoot common winding machine problems, I follow these steps:

- Listen for unusual noises or vibrations that may indicate a problem.

- Inspect the machine for any visible signs of damage or wear.

- Check sensors and other critical components to ensure they are functioning properly.

- Use diagnostic tools to identify the root cause of the issue.

- Refer to technical documentation and consult with experienced colleagues or supervisors if necessary.

5. Describe the process of setting up and calibrating a winding machine for a new yarn type.

Setting up and calibrating a winding machine for a new yarn type involves the following steps:

- Obtain the yarn specifications and winding parameters.

- Adjust the machine settings accordingly, including tension, traverse, and winding speed.

- Run test samples to ensure the yarn is being wound correctly.

- Calibrate sensors and other critical components using appropriate tools and procedures.

- Document the settings and procedures for future reference.

6. What maintenance tasks are required to keep winding machines operating smoothly?

Regular maintenance tasks are essential to keep winding machines operating smoothly and prevent breakdowns:

- Daily cleaning and inspection of the machine.

- Regular lubrication of moving parts.

- Checking and adjusting tension settings to prevent yarn breakage.

- Inspecting and cleaning sensors to ensure accuracy.

- Performing preventive maintenance tasks as per the manufacturer’s recommendations.

7. How do you stay up-to-date on the latest winding machine technology and advancements?

To stay current with the latest winding machine technology and advancements, I:

- Attend industry conferences and workshops.

- Read trade publications and technical journals.

- Connect with other professionals in the field.

- Participate in online forums and discussion groups.

- Explore new technologies and innovations at trade shows and exhibitions.

8. What quality control measures do you implement to ensure the production of high-quality wound yarn?

To ensure the production of high-quality wound yarn, I implement the following quality control measures:

- Regularly monitor yarn tension and winding parameters.

- Inspect wound packages for defects and inconsistencies.

- Use testing equipment to assess yarn quality, such as tensile strength and evenness.

- Document all quality control results and take corrective actions as necessary.

- Work closely with other departments to maintain high standards throughout the production process.

9. How do you prioritize your workload and manage multiple tasks effectively?

To prioritize my workload and manage multiple tasks effectively, I:

- Plan my day and set priorities based on urgency and importance.

- Break down large tasks into smaller, manageable steps.

- Delegate tasks to others when appropriate.

- Use technology tools, such as project management software, to stay organized.

- Communicate regularly with my supervisor and colleagues to ensure we are aligned.

10. What is your approach to working in a team environment?

In a team environment, I am:

- Collaborative and supportive, sharing knowledge and resources.

- Open to feedback and constructive criticism.

- Respectful of different perspectives and approaches.

- Willing to take on leadership roles when necessary.

- Committed to achieving team goals and objectives.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winder Fixer.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winder Fixer‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winder Fixer plays a vital role in ensuring the smooth production of wound goods in a manufacturing plant.

1. Winding Machine Maintenance

Winder Fixers are responsible for performing routine maintenance and repairs on winding machines to prevent breakdowns and keep them in optimal working condition.

- Inspect, clean, and lubricate winding machines

- Troubleshoot and resolve mechanical and electrical problems

- Replace worn or damaged parts as needed

2. Process Monitoring

They closely monitor the winding process and make necessary adjustments to ensure the production of high-quality wound goods.

- Monitor tension, speed, and other parameters during winding

- Detect and correct winding defects such as loose ends, uneven edges, or splicing errors

- Make adjustments to machine settings to optimize winding quality

3. Quality Control

Winder Fixers conduct quality control checks on wound goods to ensure they meet specified standards and customer requirements.

- Inspect wound goods for defects, including breaks, tears, or misalignment

- Rewind or discard substandard products as needed

- Keep records of quality control checks for compliance purposes

4. Safety and Compliance

They adhere to safety regulations and maintain a clean and organized work area to prevent accidents and ensure the health and safety of themselves and others.

- Follow established safety procedures and wear appropriate protective gear

- Maintain a clean and uncluttered work area

- Report any safety hazards or concerns to supervisors promptly

Interview Tips

To enhance your chances of success in the interview, consider the following preparation tips:

1. Research the Company and Position

Familiarize yourself with the company’s history, mission, and values. Learn about the specific role and its requirements to tailor your answers accordingly.

2. Practice Your Answers

Prepare thoughtful responses to common interview questions, emphasizing your relevant skills and experience. Practice delivering your answers confidently and concisely.

3. Highlight Your Technical Abilities

Demonstrate your expertise in winding machine maintenance and repair. Share examples of complex problems you have solved and the positive outcomes achieved.

4. Emphasize Your Attention to Detail

Winder Fixers must be meticulous in their work. Showcase your strong attention to detail and provide instances where you detected and resolved defects in wound goods.

5. Prepare Situational Questions

Think about potential situational questions related to your role. For instance, how you would handle a machine breakdown that affects production deadlines.

6. Dress Professionally and Arrive on Time

Make a positive first impression by dressing appropriately and arriving punctually for your interview. Be polite and respectful to everyone you meet.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winder Fixer interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!