Are you gearing up for an interview for a Winder Operator position? Whether you’re a seasoned professional or just stepping into the role, understanding what’s expected can make all the difference. In this blog, we dive deep into the essential interview questions for Winder Operator and break down the key responsibilities of the role. By exploring these insights, you’ll gain a clearer picture of what employers are looking for and how you can stand out. Read on to equip yourself with the knowledge and confidence needed to ace your next interview and land your dream job!

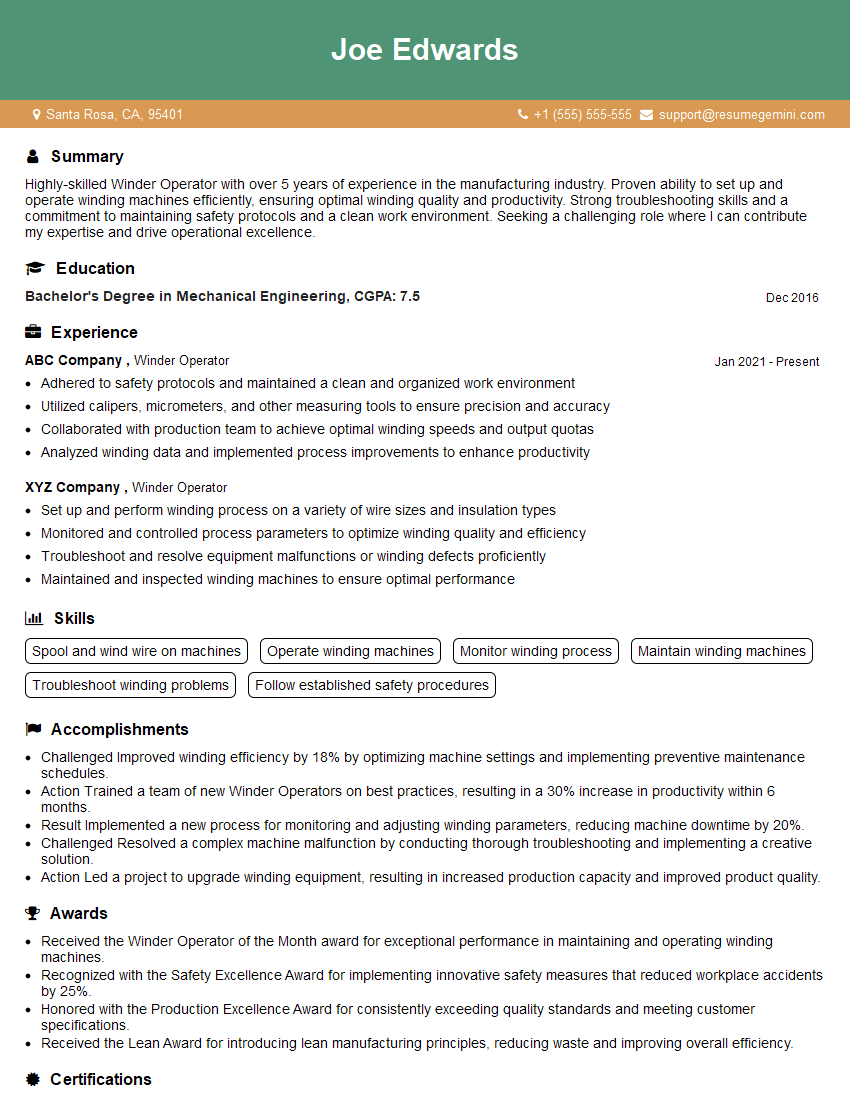

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winder Operator

1. Explain the process of winding a coil on the winder machine?

The process of winding a coil on the winder machine involves several steps:

- Prepare the wire by cutting it to the desired length and stripping the insulation from the ends.

- Mount the wire on the winder machine and secure it with clamps.

- Set the winding parameters, including the number of turns, the pitch, and the tension.

- Start the winding process and monitor the progress to ensure that the coil is being wound correctly.

- Once the winding is complete, remove the coil from the machine and inspect it for any defects.

2. What are the different types of winding patterns used in coil winding?

There are several different types of winding patterns used in coil winding, including:

Progressive Winding

- Lay the turns side-by-side in even layers.

- Each layer has the same direction of winding.

Concentric Winding

- Turns are wound in the same direction on top of each other.

- Each layer has a different winding direction.

3. How do you determine the correct tension for winding a coil?

The correct tension for winding a coil depends on several factors, including the type of wire, the size of the coil, and the winding speed.

- Too much tension can cause the wire to break.

- Too little tension can result in a loose winding that is more susceptible to damage.

4. What are the common problems that can occur during coil winding and how do you troubleshoot them?

Some common problems that can occur during coil winding include:

- Broken wires – Caused by excessive tension, improper handling, or sharp edges on the machine.

- Loose windings – Caused by insufficient tension, improper winding technique, or a worn winding head.

- Shorted turns – Caused by insulation damage, overlapping turns, or contamination.

Troubleshooting involves identifying the cause of the problem and taking corrective action, such as adjusting tension, replacing worn parts, or inspecting for damage.

5. How do you maintain and calibrate a winder machine?

Maintaining and calibrating a winder machine involves several tasks, including:

- Regularly cleaning and lubricating the machine.

- Inspecting and replacing worn or damaged parts.

- Calibrating the machine to ensure accurate winding parameters.

- Following the manufacturer’s recommended maintenance schedule.

6. What safety precautions should be taken when operating a winder machine?

When operating a winder machine, it is important to follow several safety precautions, including:

- Wear appropriate safety gear, such as gloves, safety glasses, and a lab coat.

- Keep the work area clean and free of debris.

- Be aware of the location of the emergency stop button.

- Never operate the machine with damaged or missing parts.

7. How do you ensure the quality of the coils produced on the winder machine?

Ensuring the quality of the coils produced on the winder machine involves several steps, including:

- Using high-quality materials.

- Following the manufacturer’s recommended winding parameters.

- Inspecting the coils for defects after winding.

- Testing the coils to ensure that they meet the required specifications.

8. What are the different types of coils that can be wound on a winder machine?

A winder machine can be used to wind a variety of coils, including:

- Inductor coils

- Transformer coils

- Motor coils

- Solenoid coils

9. What is the difference between a progressive winding and a concentric winding?

Progressive winding involves winding the turns of the coil side-by-side in even layers, while concentric winding involves winding the turns on top of each other.

10. What are the advantages of using a winder machine?

Using a winder machine offers several advantages, including:

- Faster winding speed

- Higher precision and accuracy

- Reduced labor costs

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winder Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winder Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Winder Operators play a pivotal role in manufacturing by operating and maintaining winding machinery to process and package materials. Their responsibilities encompass various aspects of the winding process, ensuring quality and efficiency throughout.

1. Winder Operation

Skilled in operating winding machines of varying types, Winder Operators are entrusted with meticulously coiling or wrapping materials onto spools, reels, or other designated substrates.

- Set up and adjust winding machines according to specified parameters.

- Monitor and control winding tension, speed, and other process variables to attain optimal results.

2. Material Handling

Adhering to workplace safety protocols, Winder Operators handle materials with care, ensuring their integrity and minimizing waste.

- Load and unload materials, such as yarn, wire, or paper, onto winding machines.

- Inspect materials for defects and ensure they meet quality standards before processing.

3. Quality Assurance

To maintain high standards, Winder Operators are trained to identify and rectify defects in wound materials.

- Monitor winding processes to detect interruptions or irregularities and take corrective actions.

- Inspect finished products to verify compliance with specifications, identifying and addressing any discrepancies.

4. Equipment Maintenance

Winder Operators are instrumental in maintaining the functionality and longevity of winding machinery.

- Perform routine maintenance tasks, such as cleaning, lubricating, and adjusting machines.

- Identify and report any equipment malfunctions or issues to ensure timely repairs.

Interview Tips

Preparing for a Winder Operator interview requires a holistic approach. Candidates should possess a thorough understanding of the role’s responsibilities, as well as strong communication and problem-solving skills. Here are some crucial interview tips to help you ace your interview:

1. Research the Company and Position

Before the interview, conduct thorough research on the company’s background, industry, and the specific role you are applying for. This will demonstrate your interest and enthusiasm for the opportunity.

- Visit the company’s website and social media pages to gather information about their culture, values, and recent developments.

- Review the job description meticulously to identify the key responsibilities and qualifications required for the role.

2. Prepare Your Elevator Pitch

Craft a concise and compelling 30-second to 1-minute elevator pitch that highlights your skills, experience, and why you are the ideal candidate for the position.

- Emphasize your proficiency in winding machine operation, material handling, and quality assurance.

- Quantify your accomplishments whenever possible to demonstrate your impact on previous roles.

3. Practice Active Listening and Communication

Throughout the interview, pay close attention to the interviewer’s questions and respond with clear, concise, and relevant answers. Ask clarifying questions to ensure you fully understand the requirements of the role.

- Maintain eye contact, smile, and use a professional and respectful tone of voice.

- Use specific examples from your work experience to illustrate your skills and abilities.

4. Highlight Your Problem-Solving Abilities

Winder Operators are often faced with challenges and unexpected situations. Provide examples of how you have successfully solved problems and overcome obstacles in previous roles.

- Describe a situation where you identified a problem with the winding process and implemented a solution to improve efficiency.

- Explain how you handled a defective material issue and ensured the production of high-quality products.

5. Emphasize Safety and Attention to Detail

Safety and attention to detail are paramount in the manufacturing industry. Highlight your commitment to maintaining a safe working environment and your ability to identify and address potential hazards.

- Describe your knowledge of industry safety regulations and how you ensure compliance in your work.

- Provide examples of how you have proactively identified and resolved quality issues to prevent errors.

Next Step:

Now that you’re armed with a solid understanding of what it takes to succeed as a Winder Operator, it’s time to turn that knowledge into action. Take a moment to revisit your resume, ensuring it highlights your relevant skills and experiences. Tailor it to reflect the insights you’ve gained from this blog and make it shine with your unique qualifications. Don’t wait for opportunities to come to you—start applying for Winder Operator positions today and take the first step towards your next career milestone. Your dream job is within reach, and with a polished resume and targeted applications, you’ll be well on your way to achieving your career goals! Build your resume now with ResumeGemini.