Feeling lost in a sea of interview questions? Landed that dream interview for Winding Inspector and Tester but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Winding Inspector and Tester interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

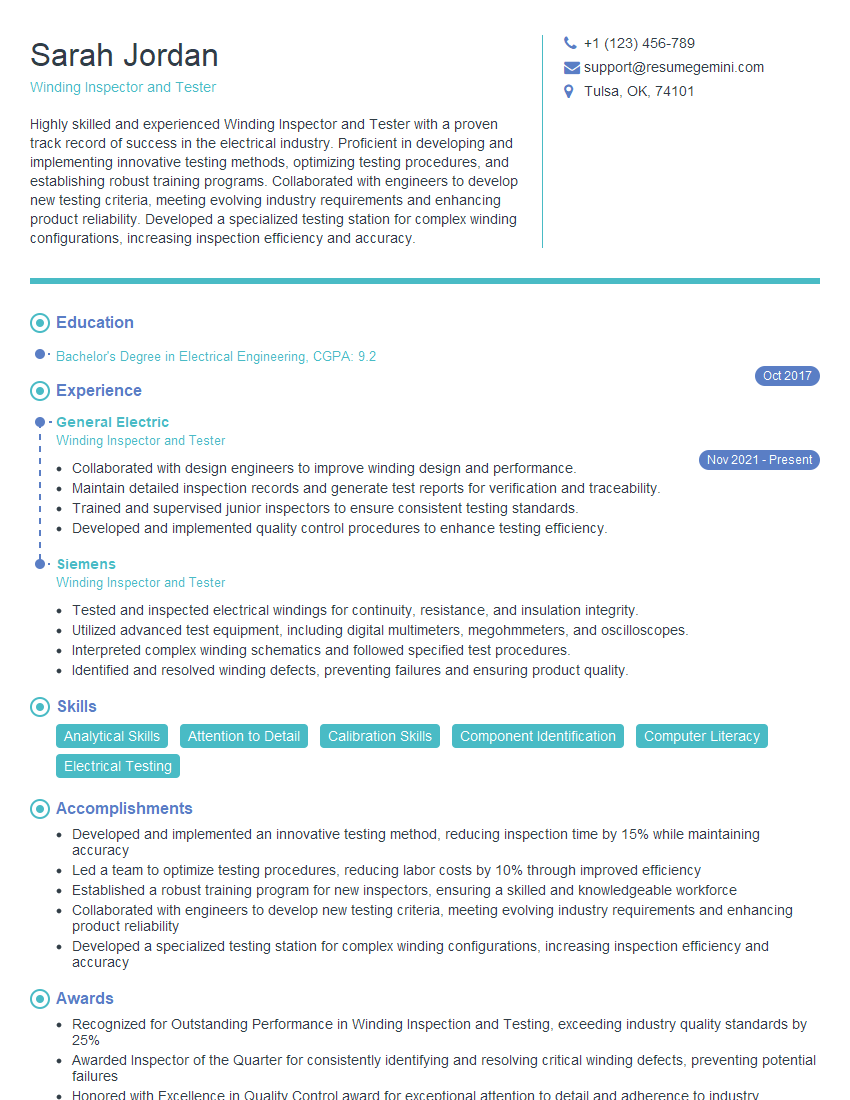

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Inspector and Tester

1. Define the primary responsibilities of a Winding Inspector and Tester?

- Inspecting and testing electrical windings for faults and defects.

- Conducting electrical, mechanical, and visual inspections.

- Using specialized testing equipment, such as continuity testers, insulation testers, and winding analyzers.

- Interpreting test results and identifying areas for improvement.

- Ensuring that windings meet specifications and quality standards.

- Documenting inspection and testing results.

- Providing feedback to manufacturing and design teams to enhance production processes.

2. Describe the different methods used to test electrical windings.

Continuity Test

- Verifies the electrical continuity of a winding.

- Checks for open circuits, breaks, and other discontinuities.

Insulation Test

- Assesses the insulation resistance of a winding.

- Prevents electrical leakage and ensures the safety of the equipment.

Winding Analysis

- Evaluates the overall performance of a winding.

- Detects imbalances, shorted turns, and other issues that may affect the efficiency of the motor.

3. How do you ensure the accuracy and reliability of your testing results?

- Calibrating testing equipment regularly.

- Following standardized testing procedures.

- Using control samples to verify the accuracy of the test results.

- Documenting the testing process and results thoroughly.

- Seeking feedback from other inspectors and testers to validate findings.

4. Discuss the importance of teamwork in the role of a Winding Inspector and Tester.

- Collaborating with manufacturing and design teams to identify and resolve issues.

- Sharing knowledge and expertise with other inspectors and testers.

- Working as part of a quality control team to ensure the production of high-quality products.

- Maintaining open communication and coordination to streamline the inspection and testing process.

5. Describe a situation where you identified a critical defect in a winding and the steps you took to resolve it.

In a recent inspection, I detected a short-circuited turn in a stator winding during a winding analysis test. I immediately notified the manufacturing team and provided them with detailed information about the fault. The team promptly investigated the issue and implemented corrective actions to prevent similar defects in future production batches. This proactive approach ensured that only high-quality products were released.

6. How do you stay updated with the latest advancements in winding inspection and testing technologies?

- Attending industry conferences and workshops.

- Reading technical journals and articles.

- Participating in online forums and discussions.

- Consulting with experts in the field.

- Researching new technologies and methodologies.

7. What is your understanding of the UL 1446 standard for electrical insulation systems?

UL 1446 is a widely recognized standard that defines the requirements and testing procedures for the evaluation of electrical insulation systems used in electrical equipment. It ensures the safety and reliability of insulation materials by specifying their thermal performance, dielectric strength, and resistance to environmental factors. As a Winding Inspector and Tester, I am familiar with the requirements of UL 1446 and incorporate them into my testing procedures to ensure compliance.

8. How do you handle discrepancies in test results obtained from different equipment or methods?

- Cross-checking results by repeating the tests.

- Investigating the equipment and methods to identify potential sources of error.

- Consulting with other inspectors or testers.

- Seeking guidance from manufacturers or experts.

- Documenting the discrepancies and the steps taken to resolve them.

9. Describe the role of automation in winding inspection and testing.

- Enhancing efficiency and productivity by automating repetitive tasks.

- Improving accuracy and consistency through precise measurements.

- Facilitating data collection and analysis for quality control and traceability.

- Reducing human error and increasing overall reliability.

10. How do you prioritize your workload when faced with multiple critical tasks?

- Assessing the urgency and impact of each task.

- Delegating tasks to team members when necessary.

- Communicating effectively with stakeholders to manage expectations.

- Using time management techniques to optimize efficiency.

- Maintaining a positive and proactive attitude even under pressure.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Inspector and Tester.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Inspector and Tester‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Winding Inspectors and Testers are essential members of the manufacturing team, responsible for ensuring the quality and reliability of electrical components. Their duties encompass a wide range of tasks, including:

1. Winding Inspection

Inspecting electrical windings for defects, including shorts, opens, and misalignments.

- Identifying and documenting any discrepancies found during inspection.

- Using specialized tools and equipment to conduct thorough examinations.

2. Electrical Testing

Performing electrical tests on windings to verify their performance and functionality.

- Measuring electrical parameters such as resistance, inductance, and capacitance.

- Analyzing test results to ensure compliance with specifications and standards.

3. Quality Control

Enforcing quality standards and ensuring that all products meet the required specifications.

- Inspecting finished products for defects and compliance with established guidelines.

- Documenting inspection results and providing feedback to the production team.

4. Troubleshooting

Diagnosing and resolving technical issues related to windings and electrical components.

- Analyzing symptoms and identifying the root causes of malfunctions.

- Implementing corrective actions to resolve issues and restore functionality.

Interview Tips

To excel in a Winding Inspector and Tester interview, candidates should focus on showcasing their technical expertise, problem-solving abilities, and attention to detail. Here are some essential tips to help prepare for the interview:

1. Research the Company and Position

Gain a thorough understanding of the company’s products, industry, and culture. Familiarize yourself with the specific job responsibilities and qualifications required for the role.

2. Prepare for Technical Questions

Review fundamental concepts related to electrical windings, testing procedures, and quality control standards. Practice answering questions about inspection techniques, troubleshooting methods, and quality assurance processes.

3. Highlight Relevant Experience and Skills

Emphasis your experience in winding inspection, electrical testing, and quality control. Quantify your accomplishments and provide specific examples of how you have contributed to improving product quality and efficiency.

4. Demonstrate Problem-Solving Abilities

Prepare to discuss situations where you have successfully diagnosed and resolved technical issues. Explain your thought process and how you applied your knowledge to find solutions.

5. Soft Skills and Communication

Emphasize your attention to detail, analytical thinking, and communication skills. Explain how you effectively collaborate with team members and communicate inspection results and troubleshooting findings.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winding Inspector and Tester interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!