Feeling lost in a sea of interview questions? Landed that dream interview for Winding Inspector but worried you might not have the answers? You’re not alone! This blog is your guide for interview success. We’ll break down the most common Winding Inspector interview questions, providing insightful answers and tips to leave a lasting impression. Plus, we’ll delve into the key responsibilities of this exciting role, so you can walk into your interview feeling confident and prepared.

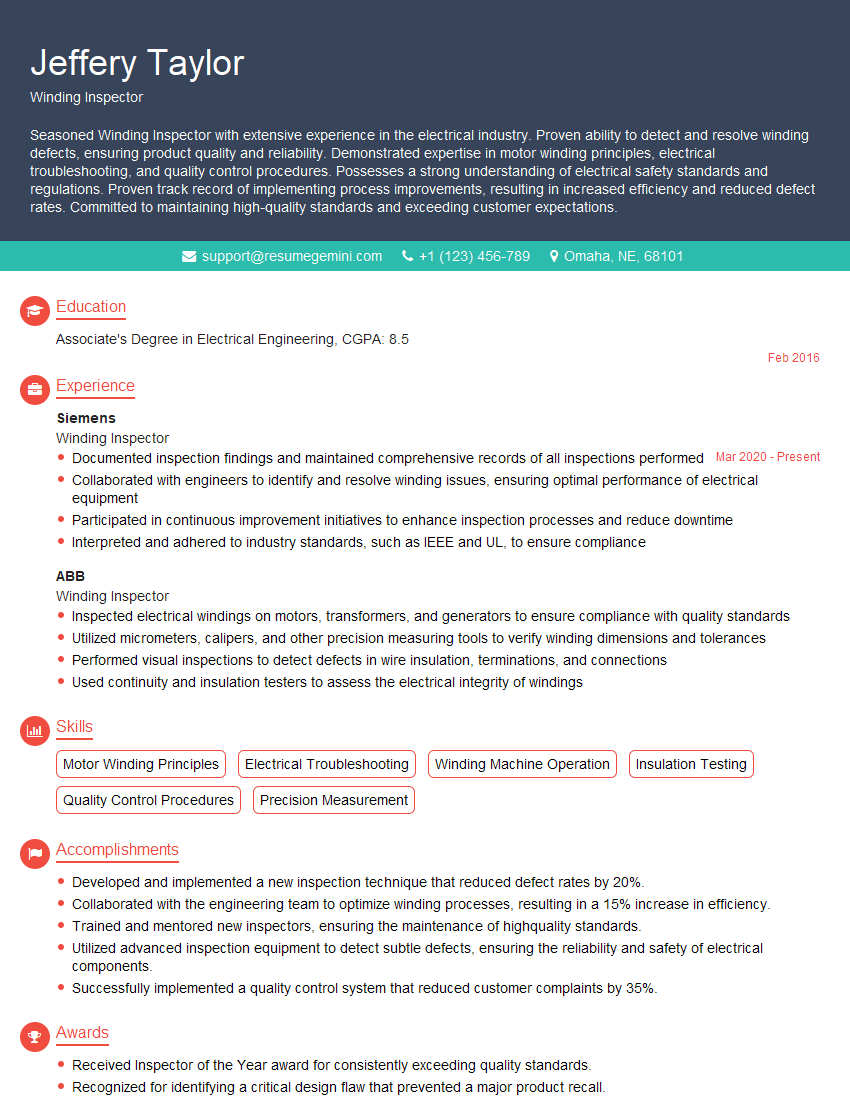

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Inspector

1. what are the different types of winding machines used in the industry?

there are many different types of winding machines used in the industry but the most common type is the coil winding machine.

2. what are the different types of windings that can be created on a winding machine?

- There are many different types of windings that can be created on a winding machine, including:

- single-layer windings

- multi-layer windings

- random windings

- precision windings

3. Describe the process of winding a coil on a winding machine.

- The process of winding a coil on a winding machine can be summarized as follows:

- The wire is fed from a spool into the winding machine.

- The wire is guided onto the coil form by a traverse mechanism.

- The wire is wound onto the coil form in the desired pattern.

- The wound coil is removed from the winding machine.

4. What are the key factors that affect the quality of a wound coil?

- The quality of a wound coil is affected by a number of factors, including:

- the type of wire used

- the type of winding machine used

- the winding parameters (such as the winding speed and tension)

- the operator’s skill level

5. Describe the different types of winding defects and how to prevent them.

- There are a number of different winding defects that can occur, including:

- shorts

- opens

- misaligned turns

- insulation damage

These defects can be prevented by using proper winding techniques and by inspecting the coils after they are wound.

6. What are the different types of winding insulation materials and their properties?

- There are a variety of different winding insulation materials available, each with its own unique properties.

- some of the most common types of winding insulation materials include:

- enamel

- varnish

- paper

- fiberglass

The type of winding insulation material used will depend on the application and the required properties.

7. What are the different types of winding test equipment and their uses?

- There are a variety of different winding test equipment available, each with its own unique uses.

- some of the most common types of winding test equipment include:

- hipot testers

- insulation testers

- continuity testers

The type of winding test equipment used will depend on the application and the required tests.

8. What are the different types of winding repair techniques?

- There are a number of different winding repair techniques available, depending on the type of damage.

- some of the most common winding repair techniques include:

- soldering

- welding

- insulation repair

The type of winding repair technique used will depend on the application and the required repair.

9. What are the different types of winding safety precautions?

- There are a number of different winding safety precautions that should be followed, including:

- wearing appropriate safety gear

- using proper winding techniques

- inspecting coils after they are wound

- following all safety procedures

By following these safety precautions, you can help to prevent accidents and injuries.

10. What are the different types of winding quality control procedures?

- There are a number of different winding quality control procedures that can be followed, including:

- visual inspection

- electrical testing

- dimensional measurement

By following these quality control procedures, you can help to ensure that your coils meet the required specifications

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Inspector.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Inspector‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winding Inspector plays a crucial role in ensuring the quality and reliability of electrical components by scrutinizing various aspects of wound coils. Their responsibilities encompass multiple facets of inspection, focusing on identifying and rectifying defects.

1. Visual Inspections

Inspect coils visually for any apparent defects, such as improper winding patterns, damaged insulation, or loose connections.

- Examine coil winding to ensure compliance with specifications and blueprints.

- Identify and rectify deviations from standard winding patterns.

2. Electrical Testing

Perform electrical tests to assess coil performance, insulation integrity, and resistance levels.

- Conduct continuity tests to verify proper electrical connections.

- Measure insulation resistance to ensure adequate protection against electrical breakdown.

3. Dimensional Measurements

Utilize precision measuring tools to ensure coils meet specified dimensions and tolerances.

- Measure coil dimensions, such as length, width, and height.

- Verify that coil dimensions conform to design specifications and drawings.

4. Record Keeping and Reporting

Maintain accurate records of inspection findings and provide timely reports to stakeholders.

- Document inspection results, including defects identified and corrective actions taken.

- Communicate inspection findings and recommendations to production and engineering teams.

Interview Tips

To ace the Winding Inspector interview, candidates should meticulously prepare by researching the role and company, practicing common interview questions, and showcasing their skills and experience.

1. Research the Role and Company

Thoroughly research the Winding Inspector role and the specific industry or company you are applying to. Understand the company’s products, processes, and quality standards.

- Visit the company’s website and social media pages to gather information.

- Read industry publications and articles to stay informed about current trends and best practices.

2. Practice Common Interview Questions

Prepare for common interview questions by rehearsing your answers and using specific examples to demonstrate your skills and experience. Consider questions such as:

- Tell me about your experience in winding inspection.

- Describe a situation where you identified and resolved a winding defect.

- How do you ensure accuracy and reliability in your inspections?

3. Showcase Your Skills and Experience

Highlight your proficiency in winding inspection techniques, electrical testing methods, and dimensional measurements. Emphasize your attention to detail, analytical abilities, and commitment to quality.

- Quantify your accomplishments whenever possible, using metrics to demonstrate your impact.

- Prepare examples of successful inspections where you identified and resolved critical defects.

4. Be Enthusiastic and Professional

Demonstrate your enthusiasm for the role and your eagerness to contribute to the team’s success. Maintain a professional demeanor throughout the interview, making eye contact, asking thoughtful questions, and thanking the interviewer for their time.

- Express your interest in the company and the industry.

- Ask questions to show your engagement and understanding of the role.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winding Inspector interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!