Are you gearing up for a career shift or aiming to ace your next interview? Look no further! We’ve curated a comprehensive guide to help you crack the interview for the coveted Winding Lathe Operator position. From understanding the key responsibilities to mastering the most commonly asked questions, this blog has you covered. So, buckle up and let’s embark on this journey together.

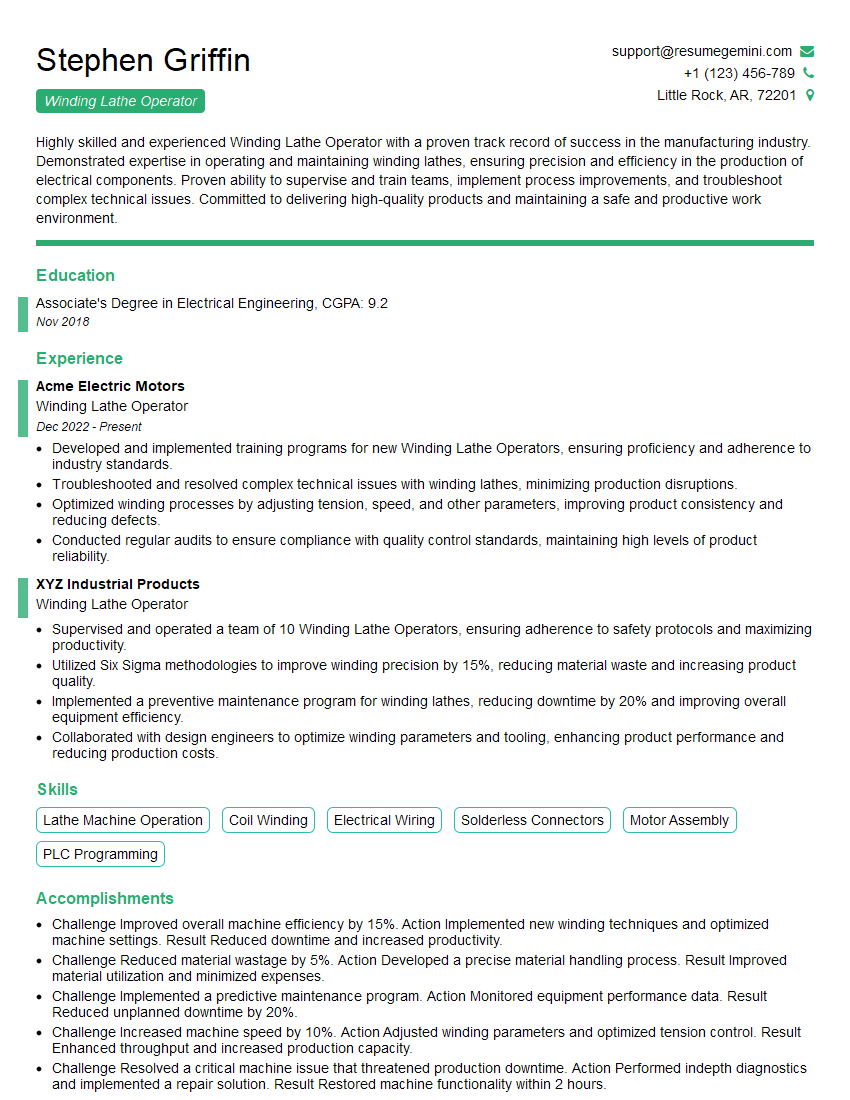

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Lathe Operator

1. How do you determine the correct winding tension for different types of wire?

- Calculate the correct tension based on the wire’s diameter and material properties.

- Use a tension gauge to measure the actual tension applied.

- Adjust the tension as needed to ensure proper winding quality.

2. What are the different types of winding patterns used for motors and generators?

Progressive winding

- Each coil is connected in series with the next, forming a continuous loop.

- Provides a smooth and evenly distributed magnetic field.

Lap winding

- Coils are connected in parallel, forming multiple closed loops.

- Results in a higher voltage output.

3. How do you troubleshoot and repair winding faults in electric motors?

- Identify the type of fault using diagnostic tools (e.g., megger).

- Locate the faulty winding using a winding diagram.

- Repair the fault by replacing damaged wires or insulation.

- Test the motor to ensure proper operation after repair.

4. What are the safety precautions that must be followed when operating a winding lathe?

- Wear appropriate PPE (e.g., gloves, safety glasses).

- Ensure the lathe is properly grounded.

- Secure the wire to the lathe spindle to prevent entanglement.

- Keep the work area clean and well-lit.

5. How do you calculate the number of turns required for a specific winding project?

- Determine the required magnetic field strength.

- Calculate the number of ampere-turns based on the motor or generator specifications.

- Select a suitable wire size and calculate the number of turns using the formula: Number of turns = Ampere-turns / (Current per turn).

6. What are the key factors that affect the quality of a wound coil?

- Proper wire tension

- Uniform winding pattern

- Adequate insulation

- Absence of short circuits or ground faults

7. How do you ensure the accuracy and precision of your winding work?

- Use calibrated equipment (e.g., tension gauge, winding machine).

- Follow established winding procedures and specifications.

- Inspect completed windings for defects.

- Continuously improve skills through training and experience.

8. What are the different types of winding machines used in the industry?

- Manual winding machines

- Semi-automatic winding machines

- Fully-automatic winding machines

- CNC winding machines

9. How do you maintain and calibrate winding machines?

- Regularly clean and lubricate machines.

- Calibrate tension gauges and other measuring devices.

- Follow manufacturer’s guidelines for maintenance and calibration.

- Keep maintenance records to ensure compliance.

10. How do you stay updated with the latest advancements in winding technology?

- Attend industry conferences and workshops.

- Read technical articles and journals.

- Network with other winding professionals.

- Participate in online forums and discussion groups.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Lathe Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Lathe Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

Winding Lathe Operators play a crucial role in various industries by operating and monitoring winding lathes to produce electrical coils, transformers, motors, and other components. Their key job responsibilities include:

1. Machine Operation and Setup

Setting up the winding lathe according to specifications and blueprints

- Positioning and securing the coil form or armature

- Selecting and loading the appropriate wire or conductor

2. Winding and Insulation

Operating the lathe to wind the wire or conductor onto the coil form with precision and accuracy

- Maintaining consistent tension and winding patterns

- Applying insulation materials between layers or windings to prevent short circuits

3. Quality Control and Inspection

Inspecting finished coils for defects and ensuring compliance with specifications

- Using precision measuring tools and gauges to verify dimensions and tolerances

- Identifying and rectifying any irregularities or errors

4. Maintenance and Troubleshooting

Performing preventive maintenance tasks to ensure optimal performance of the winding lathe

- Cleaning and lubricating machine components

- Troubleshooting and resolving operational issues

Interview Tips

Preparing for a Winding Lathe Operator interview requires a combination of technical knowledge and presentation skills. Here are some tips to help candidates ace the interview:

1. Research the Company and Position

Read the job description thoroughly and visit the company’s website to gain insights into their products, services, and culture

- Tailor your answers to the specific requirements of the role.

- Prepare questions to ask the interviewer about the company and the position.

2. Highlight Relevant Skills and Experience

Quantify your accomplishments and provide specific examples of your winding lathe operating skills, quality control processes, and troubleshooting abilities.

- Use action verbs and metrics to describe your contributions and impact.

- Mention any certifications or training programs that enhance your qualifications.

3. Practice Technical Questions

Be prepared to answer questions about winding lathe operation, coil design, insulation materials, and quality control standards

- Review the basics of winding techniques, such as progressive and random winding.

- Familiarize yourself with different types of insulation materials and their applications.

4. Emphasize Safety and Attention to Detail

Winding Lathe Operators must prioritize safety and maintain a meticulous approach to their work.

- Explain your understanding of safety protocols and your commitment to maintaining a safe work environment.

- Provide examples of situations where you demonstrated attention to detail and accuracy.

Next Step:

Armed with this knowledge, you’re now well-equipped to tackle the Winding Lathe Operator interview with confidence. Remember, preparation is key. So, start crafting your resume, highlighting your relevant skills and experiences. Don’t be afraid to tailor your application to each specific job posting. With the right approach and a bit of practice, you’ll be well on your way to landing your dream job. Build your resume now from scratch or optimize your existing resume with ResumeGemini. Wish you luck in your career journey!