Are you gearing up for a career in Winding Machine Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Winding Machine Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

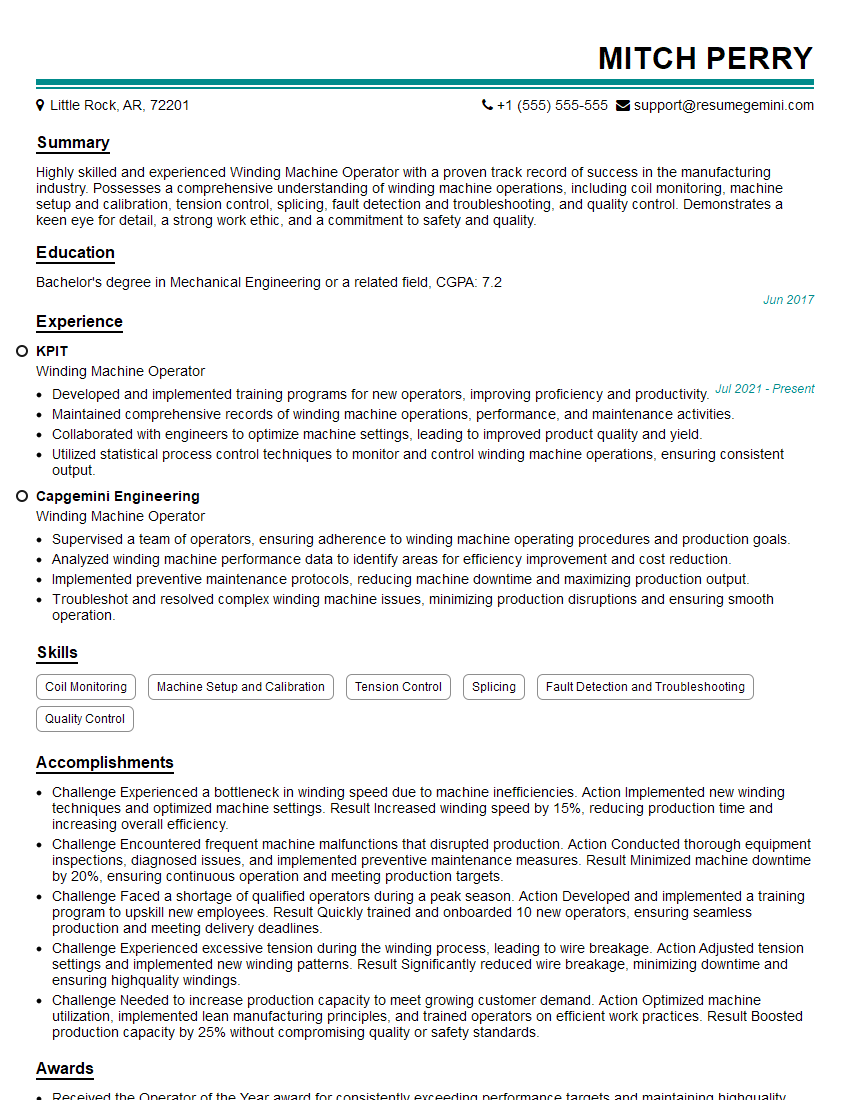

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Machine Operator

1. How do you determine the correct tension during winding?

To determine the correct tension during winding, I consider the following factors:

- Wire type and material: Different wire types and materials have different tensile strengths and require different tension settings.

- Winding speed: Higher winding speeds require higher tension to prevent wire breakage.

- Coil geometry: The size, shape, and number of turns in the coil influence the required tension.

2. Explain the winding machine’s electrical system.

Power Supply

- Provides electrical power to the machine.

- Consists of a transformer, rectifier, and filter.

Control Circuit

- Controls the machine’s operation.

- Includes a PLC, sensors, and switches.

Drive System

- Converts electrical power into mechanical motion.

- Consists of a motor, encoder, and drive.

3. What steps do you take to maintain the winding machine?

My regular maintenance routine includes:

- Cleaning and lubrication: Lubricating moving parts and cleaning debris to prevent wear and tear.

- Calibration and adjustments: Calibrating sensors, adjusting tension settings, and checking machine alignment.

- Inspections: Regularly inspecting electrical components, wiring, and mechanical parts for any signs of damage.

4. How do you troubleshoot common winding problems?

I follow a systematic approach to troubleshoot winding problems:

- Identify the symptom: Describe the specific problem encountered, such as wire breakage, uneven winding, or incorrect coil dimensions.

- Check the equipment: Inspect the winding machine, wire supply, and tooling for any visible defects or malfunctions.

- Analyze the process: Review the winding parameters, tension settings, and other factors that may be affecting the problem.

- Adjust or repair: Make necessary adjustments to the machine or process based on the identified issue.

5. Describe the different types of winding patterns and their applications.

There are several common winding patterns used for different applications:

- Layer winding: Used for low-voltage coils with a low number of turns.

- Helical winding: Used for high-voltage coils with a large number of turns.

- Universal winding: A combination of layer and helical winding, suitable for a wide range of applications.

6. How do you ensure the safety of the winding machine and yourself while operating?

I prioritize safety by adhering to the following measures:

- Machine guarding: Verify that all safety guards and covers are in place and functioning properly.

- Lockout/tagout procedures: Follow established procedures for isolating and de-energizing the machine before maintenance or repairs.

- PPE: Wear appropriate personal protective equipment, such as safety glasses, gloves, and hearing protection.

7. Explain the importance of quality control in winding operations.

Quality control is crucial in winding operations to ensure:

- Customer satisfaction: High-quality windings lead to reliable and efficient end products.

- Production efficiency: Reduced defects minimize downtime and scrap.

- Compliance with standards: Adherence to industry and regulatory standards ensures safety and performance.

8. Describe your experience with winding different wire types and gauges.

I have experience winding a variety of wire types and gauges, including:

- Copper: Widely used in electrical applications.

- Aluminum: Lightweight and corrosion-resistant.

- Magnet wire: Used in transformers and motors.

9. How do you handle complex winding operations, such as multilayer or multi-section coils?

For complex winding operations, I utilize advanced techniques to ensure accuracy and efficiency:

- Pre-winding setup: Plan the winding pattern and determine the necessary tooling.

- Precise tension control: Adjust the tension settings for each layer or section to prevent wire damage.

- Specialized tooling: Use specialized tooling to guide and hold the wire during complex winding operations.

10. What quality assurance measures do you implement to ensure the accuracy and reliability of your winding operations?

I implement the following quality assurance measures:

- Visual inspection: Regularly inspect wound coils for any defects or inconsistencies.

- Electrical testing: Perform electrical tests, such as insulation resistance and continuity, to ensure proper functionality.

- Dimensional measurement: Measure the dimensions of wound coils to verify compliance with specifications.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Machine Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Machine Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

The Winding Machine Operator plays a vital role in manufacturing a diverse range of products, including electrical equipment, transformers, and motors. Their responsibilities encompass the operation, monitoring, and maintenance of winding machines to produce coils with precise specifications.

1. Machine Operation and Setup

Execute machine setup processes as per specified instructions, including adjusting tension levels, wire speed, and winding patterns.

- Follow standard operating procedures (SOPs) and ensure machine settings align with production requirements.

- Load wire or other materials onto winding machines and initiate the winding process.

2. Quality Control and Inspection

Monitor and inspect coils throughout the winding process to ensure they meet quality standards and specifications.

- Identify and rectify any defects or deviations in the winding process.

- Conduct testing and measurements to verify coil properties, such as resistance, inductance, and insulation integrity.

3. Production Planning and Scheduling

Understand production schedules and plan winding operations accordingly to meet deadlines.

- Coordinate with other manufacturing teams to ensure a smooth production flow.

- Monitor machine output and adjust parameters to optimize production efficiency.

4. Machine Maintenance and Troubleshooting

Perform routine maintenance and troubleshooting tasks to ensure optimal machine performance and prevent breakdowns.

- Clean and lubricate machine components according to maintenance schedules.

- Identify and resolve minor operational issues to minimize downtime.

Interview Tips

Preparing for an interview for the role of Winding Machine Operator requires a combination of technical knowledge, industry-specific skills, and interview preparedness strategies. Here are some key tips to help you ace the interview:

1. Research the Company and Position

Thoroughly research the company’s background, products or services, and company culture to demonstrate your interest and understanding of their operations.

- Review the job description carefully and identify the key requirements and responsibilities.

- Connect with current or former employees on LinkedIn to gain insights into the company’s work environment and expectations.

2. Prepare for Technical Questions

Expect questions related to your technical skills and experience in operating winding machines.

- Practice explaining your proficiency in machine setup, wire handling, and quality control procedures.

- Be prepared to discuss your troubleshooting abilities and how you handle common operational issues.

3. Emphasize Safety and Attention to Detail

Highlight your commitment to safety and your meticulous attention to detail in your responses.

- Provide examples of how you ensure a safe working environment and adhere to safety protocols.

- Describe your methods for inspecting coils and maintaining high-quality standards in your previous roles.

4. Showcase Your Problem-Solving Abilities

Demonstrate your problem-solving skills by sharing real-life examples of how you identified and resolved operational challenges.

- Use the STAR method (Situation, Task, Action, Result) to structure your answers and provide specific details.

- Explain how you analyzed the problem, developed solutions, and implemented them to improve machine efficiency or product quality.

5. Ask Thoughtful Questions

Ask well-prepared questions during the interview to show your interest and engagement with the role and the company.

- Inquire about opportunities for professional development and advancement within the organization.

- Ask about the company’s commitment to quality control and customer satisfaction.

Next Step:

Now that you’re armed with the knowledge of Winding Machine Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Winding Machine Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini