Are you gearing up for a career in Winding Operator? Feeling nervous about the interview questions that might come your way? Don’t worry, you’re in the right place. In this blog post, we’ll dive deep into the most common interview questions for Winding Operator and provide you with expert-backed answers. We’ll also explore the key responsibilities of this role so you can tailor your responses to showcase your perfect fit.

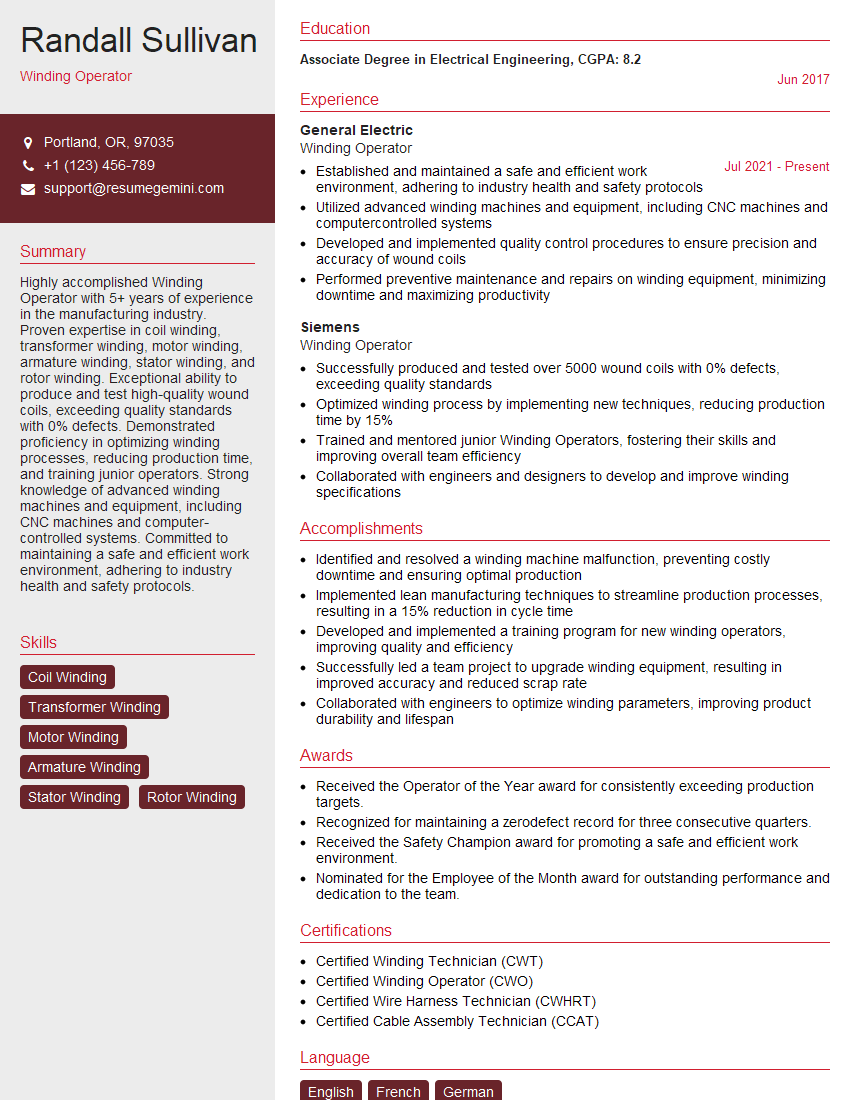

Acing the interview is crucial, but landing one requires a compelling resume that gets you noticed. Crafting a professional document that highlights your skills and experience is the first step toward interview success. ResumeGemini can help you build a standout resume that gets you called in for that dream job.

Essential Interview Questions For Winding Operator

1. what is the purpose of tension in winding?

The purpose of tension in winding is to:

- Control the tightness and uniformity of the winding.

- Prevent the wire from breaking or slipping during winding.

- Ensure that the windings are properly seated in the slots or on the core.

- Minimize the risk of electrical shorts or insulation failures.

2. What are the different types of winding machines?

Manual winding machines

- Used for small-scale production or prototyping.

- Require skilled operators.

- Relatively slow and inefficient.

Semi-automatic winding machines

- Used for medium-scale production.

- Offer some automation, such as automatic wire feeding and winding.

- Require less skilled operators than manual machines.

Fully-automatic winding machines

- Used for high-volume production.

- Highly automated, with little or no operator intervention required.

- Offer high precision and efficiency.

3. What are the key factors to consider when selecting a winding machine?

The key factors to consider when selecting a winding machine include:

- The type and size of wire to be wound.

- The required winding speed and accuracy.

- The desired level of automation.

- The available budget.

- The production volume.

4. How do you ensure the quality of wound coils?

To ensure the quality of wound coils, I follow several key steps, including:

- Inspecting the wire for any defects or damage before winding.

- Calibrating the winding machine to ensure accurate winding parameters.

- Monitoring the winding process to identify any potential issues.

- Testing the wound coils for electrical continuity and insulation resistance.

- Implementing quality control measures throughout the winding process.

5. What are the common winding defects and how do you prevent them?

Common winding defects include:

- Shorted turns: Caused by wire insulation damage or overlapping turns. Prevented by using high-quality wire and ensuring proper winding techniques.

- Open turns: Caused by breaks in the wire. Prevented by inspecting the wire before winding and using tension control to avoid wire breakage.

- Layer shorts: Caused by adjacent layers of winding touching. Prevented by using insulation between layers and maintaining proper winding tension.

- Ground faults: Caused by the winding touching the core or other grounded components. Prevented by using insulation and ensuring that the winding is properly seated.

6. what is the difference between single-layer and multi-layer winding?

Single-layer winding involves winding a single layer of wire around the core, while multi-layer winding involves winding multiple layers of wire on top of each other.

Single-layer winding

- Used for low-voltage, high-current applications.

- Provides good heat dissipation.

- Relatively easy to wind.

Multi-layer winding

- Used for high-voltage, low-current applications.

- Provides higher inductance.

- More difficult to wind due to the need for insulation between layers.

7. what are the factors that affect the efficiency of a transformer?

Factors that affect the efficiency of a transformer include:

- Core losses: Losses due to hysteresis and eddy currents in the core.

- Copper losses: Losses due to the resistance of the windings.

- Stray losses: Losses due to leakage flux and other factors.

- Design factors: The design of the transformer, including the core material, winding configuration, and insulation.

- Operating conditions: The load and voltage conditions under which the transformer is operating.

8. How do you troubleshoot a transformer that is not performing properly?

To troubleshoot a transformer that is not performing properly, I follow several steps, including:

- Inspecting the transformer for any physical damage or defects.

- Measuring the input and output voltages and currents.

- Checking the insulation resistance of the windings.

- Performing a turns ratio test.

- Analyzing the test results to identify the source of the problem.

9. what are the safety precautions that should be taken when working with transformers?

When working with transformers, it is important to take several safety precautions, including:

- Ensuring that the transformer is properly grounded.

- Wearing appropriate personal protective equipment (PPE), such as gloves and safety glasses.

- Working in a well-ventilated area.

- Avoiding touching any exposed electrical components.

- Following all manufacturer’s instructions and safety guidelines.

10. What are your career goals as a Winding Operator?

My career goals as a Winding Operator are to:

- Become a skilled and experienced operator.

- Contribute to the production of high-quality transformers.

- Advance my knowledge and skills through training and experience.

- Take on additional responsibilities and challenges.

- Eventually move into a supervisory or management role.

Interviewers often ask about specific skills and experiences. With ResumeGemini‘s customizable templates, you can tailor your resume to showcase the skills most relevant to the position, making a powerful first impression. Also check out Resume Template specially tailored for Winding Operator.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Great Savings With New Year Deals and Discounts! In 2025, boost your job search and build your dream resume with ResumeGemini’s ATS optimized templates.

Researching the company and tailoring your answers is essential. Once you have a clear understanding of the Winding Operator‘s requirements, you can use ResumeGemini to adjust your resume to perfectly match the job description.

Key Job Responsibilities

A Winding Operator is a skilled professional who operates winding machines to produce coils and windings for various electrical components. The primary responsibilities include:

1. Machine Operation and Maintenance

Operate and maintain winding machines, ensuring smooth and efficient functioning.

- Set up and adjust winding parameters based on product specifications.

- Monitor machine performance, troubleshoot problems, and perform basic repairs.

- Maintain a clean and organized work area.

2. Coil and Winding Production

Produce coils and windings according to specifications, using appropriate materials and techniques.

- Handle and inspect raw materials, such as wire and insulation.

- Wind coils and windings to precise dimensions and tolerances.

- Ensure the quality of finished products by conducting inspections and tests.

3. Production Planning and Monitoring

Plan and monitor production schedules to meet customer demands.

- Coordinate with other departments to ensure timely delivery of products.

- Monitor production rates and adjust processes to optimize efficiency.

- Identify bottlenecks and implement solutions to improve productivity.

4. Safety and Compliance

Adhere to safety protocols and maintain a safe work environment.

- Follow established safety procedures and wear appropriate protective gear.

- Comply with industry regulations and quality standards.

- Report any safety hazards or incidents to management.

Interview Tips

To ace your interview for a Winding Operator position, consider the following tips:

1. Research the Company and Role

Gather information about the company’s products, services, and industry. Understand the specific responsibilities and qualifications required for the role.

- Visit the company website and read about their mission, values, and recent projects.

- Review the job description carefully and identify the key skills and experience they are seeking.

2. Practice Your Answers

Anticipate common interview questions and prepare your responses. Focus on highlighting your relevant skills and experience.

- Explain your experience in operating winding machines and producing coils and windings.

- Describe your understanding of quality control and production standards.

- Share examples of how you have improved efficiency or resolved problems in previous roles.

3. Emphasize Your Commitment to Safety

Safety is paramount in a Winding Operator position. Demonstrate your understanding of safety protocols and your commitment to working in a safe environment.

- Describe your experience following safety procedures and wearing appropriate protective gear.

- Explain how you would handle a safety hazard or incident.

- Mention any safety training or certifications you have obtained.

4. Ask Thoughtful Questions

Asking thoughtful questions shows your interest in the role and the company. Prepare a few questions to ask the interviewer about the company’s goals, challenges, or opportunities.

- Inquire about the company’s plans for future product development or market expansion.

- Ask how the company measures success in the role of a Winding Operator.

- Request more information about the training and development opportunities available.

Next Step:

Now that you’re armed with the knowledge of Winding Operator interview questions and responsibilities, it’s time to take the next step. Build or refine your resume to highlight your skills and experiences that align with this role. Don’t be afraid to tailor your resume to each specific job application. Finally, start applying for Winding Operator positions with confidence. Remember, preparation is key, and with the right approach, you’ll be well on your way to landing your dream job. Build an amazing resume with ResumeGemini